Jan 3, 2026

Jan 3, 2026

Top 5 Manufacturing Eco-Industrial Parks Worldwide

Sustainability Strategy

Sustainability Strategy

In This Article

Shared energy, water and waste systems in eco-industrial parks show how industrial symbiosis and renewables cut costs, save resources, and lower emissions.

Top 5 Manufacturing Eco-Industrial Parks Worldwide

Eco-Industrial Parks (EIPs) are transforming manufacturing by turning waste into resources, cutting costs, and reducing environmental impact. These parks integrate businesses to share resources like energy, water, and waste systems, creating efficient and collaborative ecosystems. Here are five leading examples:

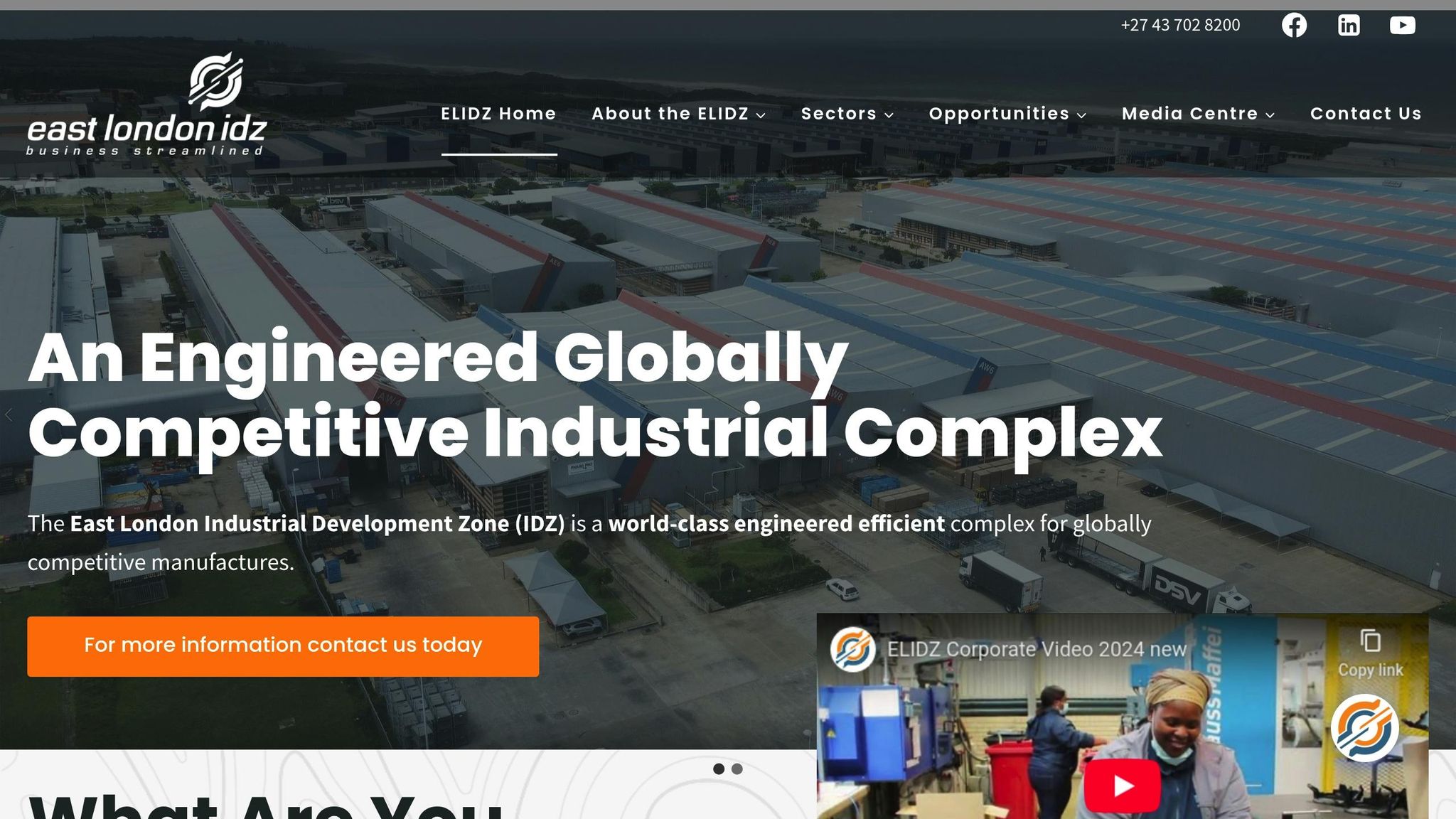

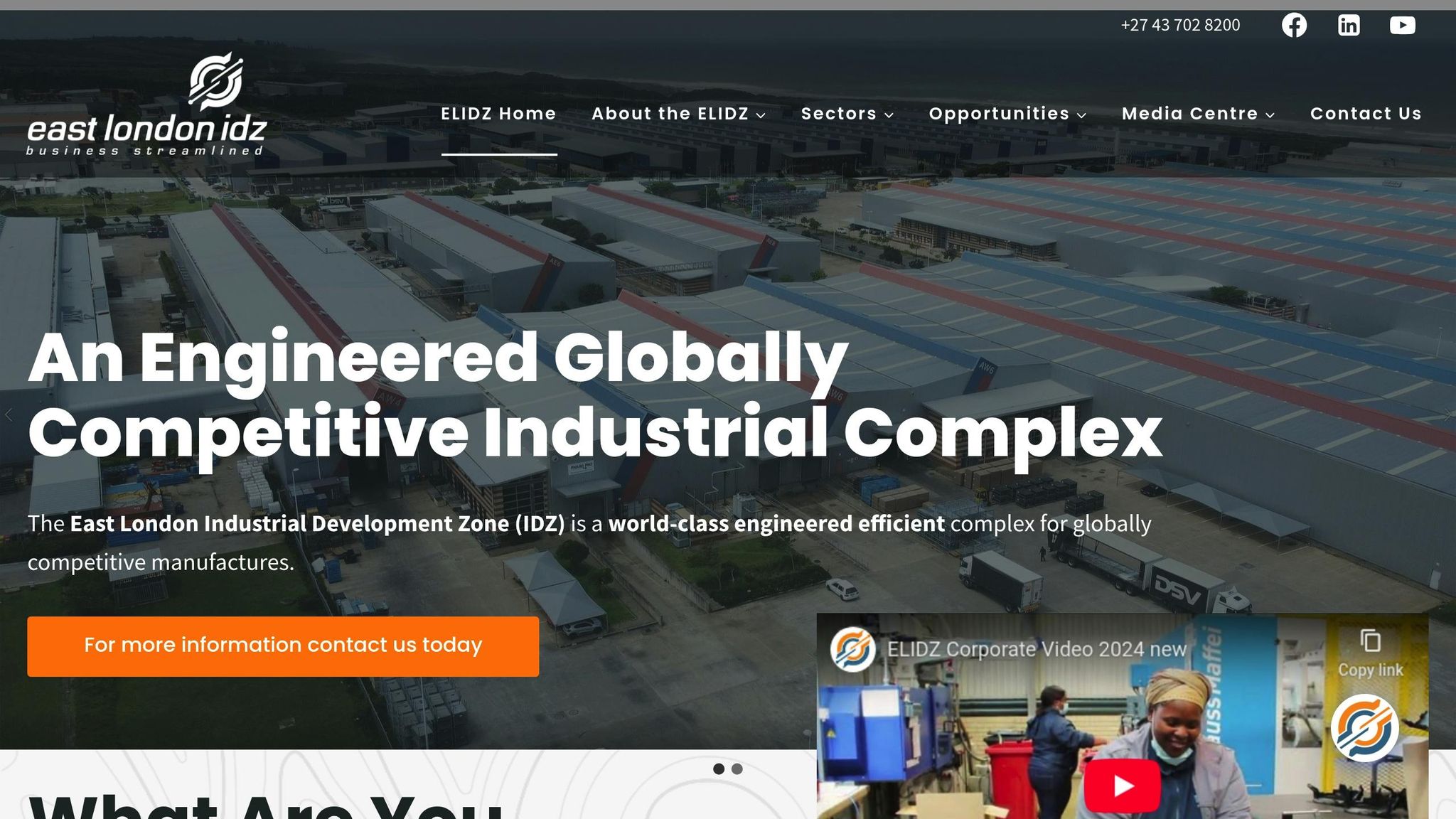

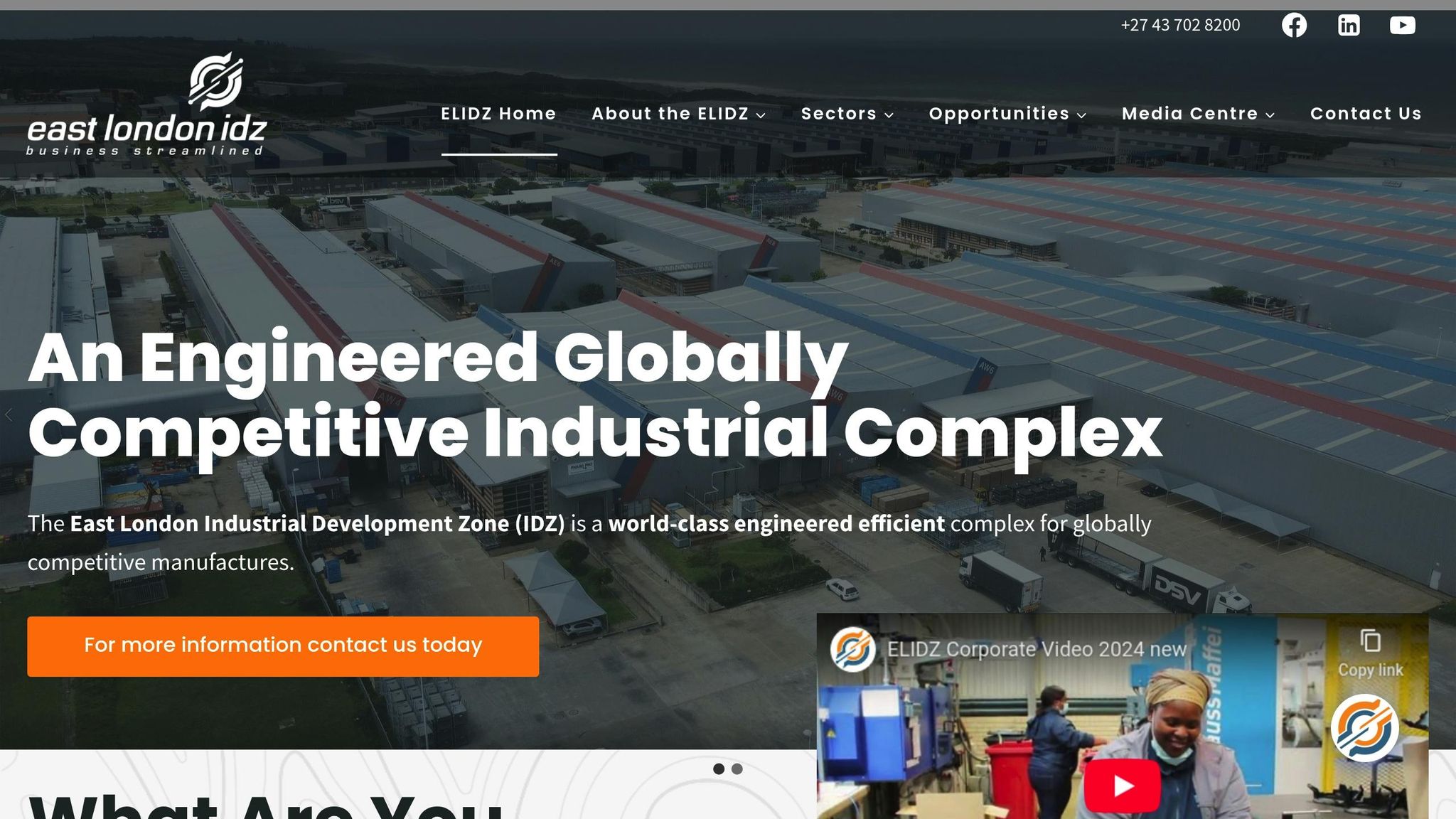

East London Industrial Development Zone (South Africa): Focuses on resource efficiency, industrial symbiosis, and renewable energy, generating over 3,945 jobs and saving costs through shared infrastructure.

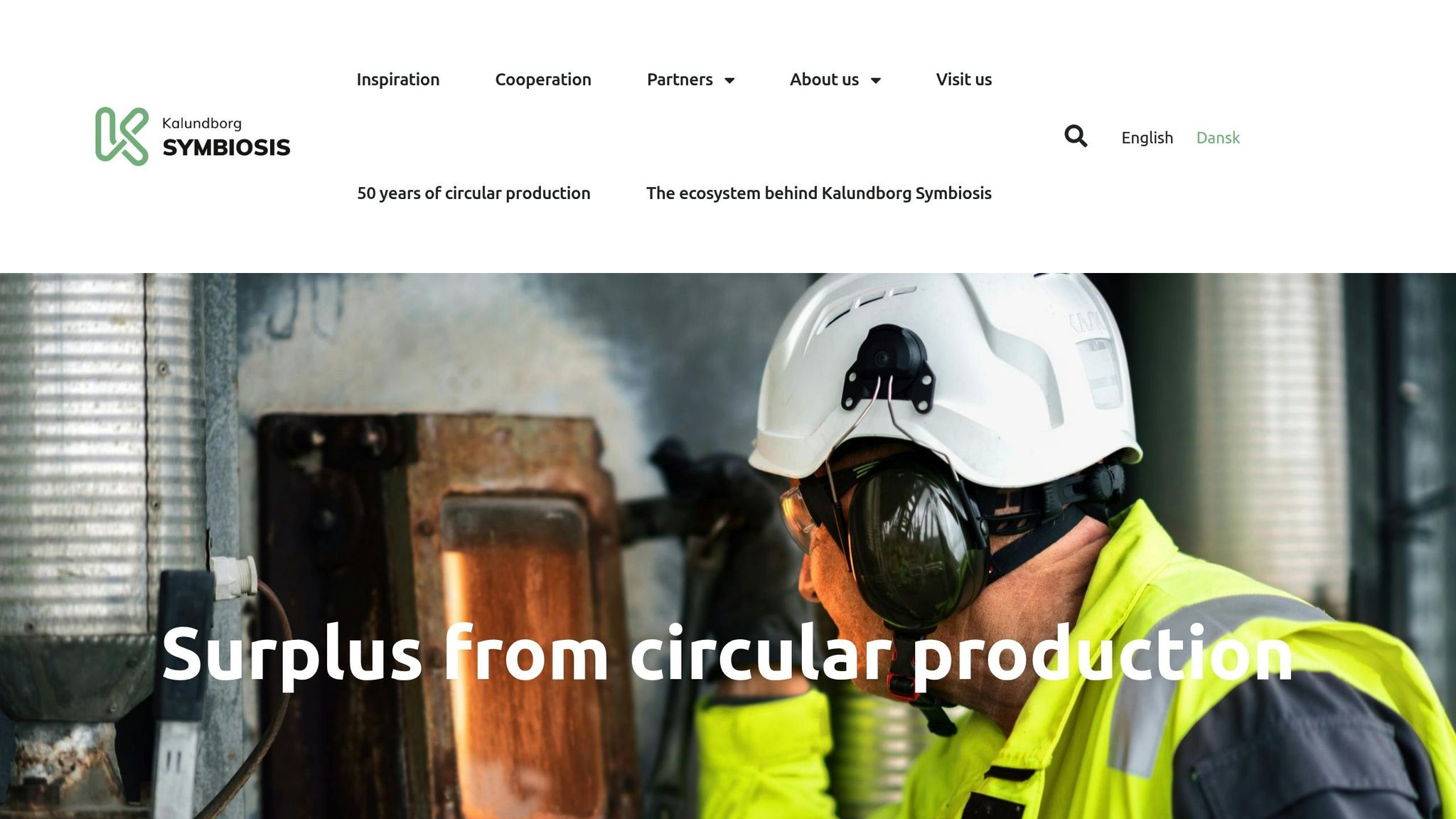

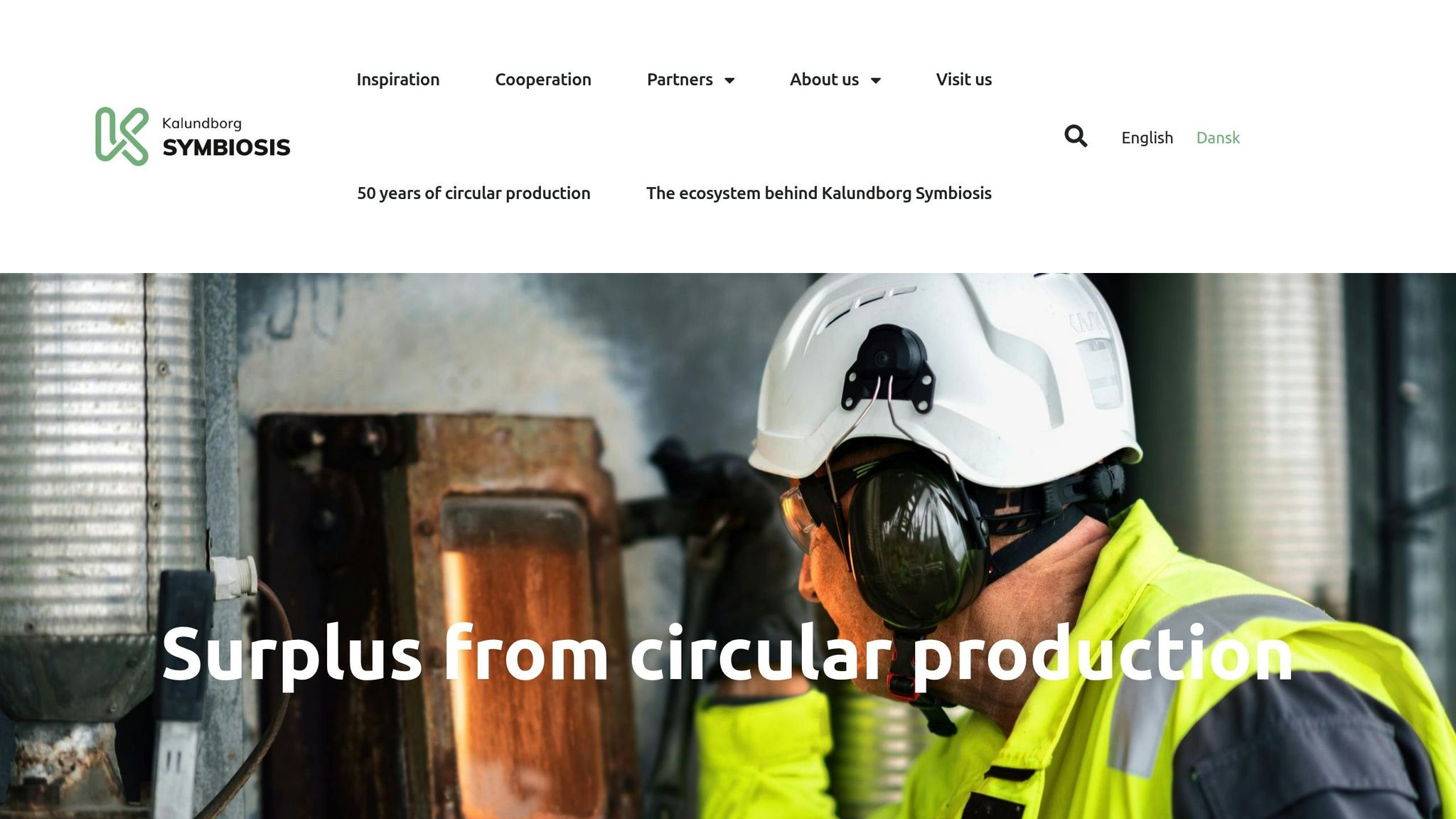

Kalundborg Symbiosis (Denmark): A pioneer in industrial symbiosis, saving 586,000 tons of CO₂ annually and achieving $72–$87 million in yearly savings by reusing resources across 12 businesses.

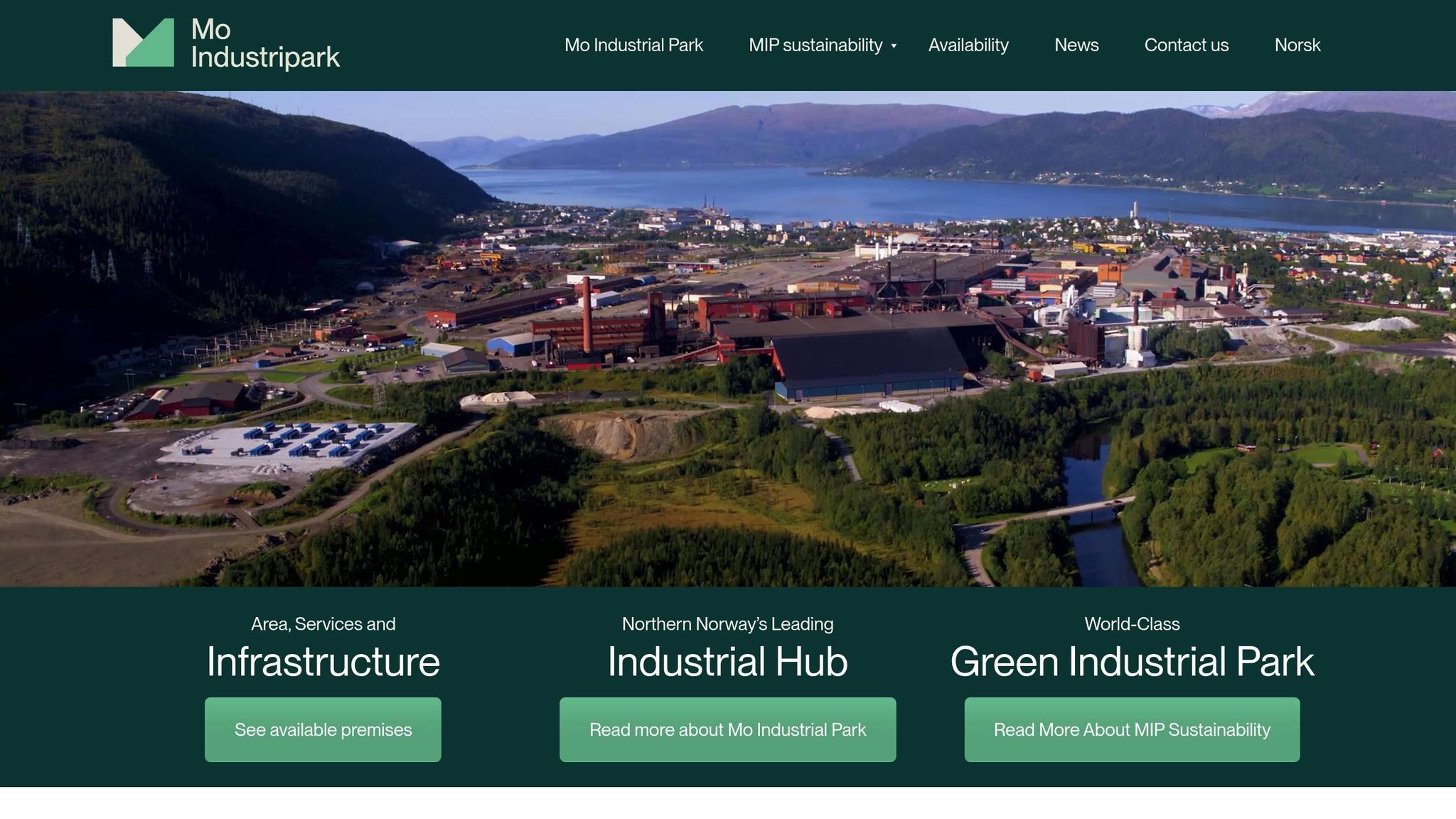

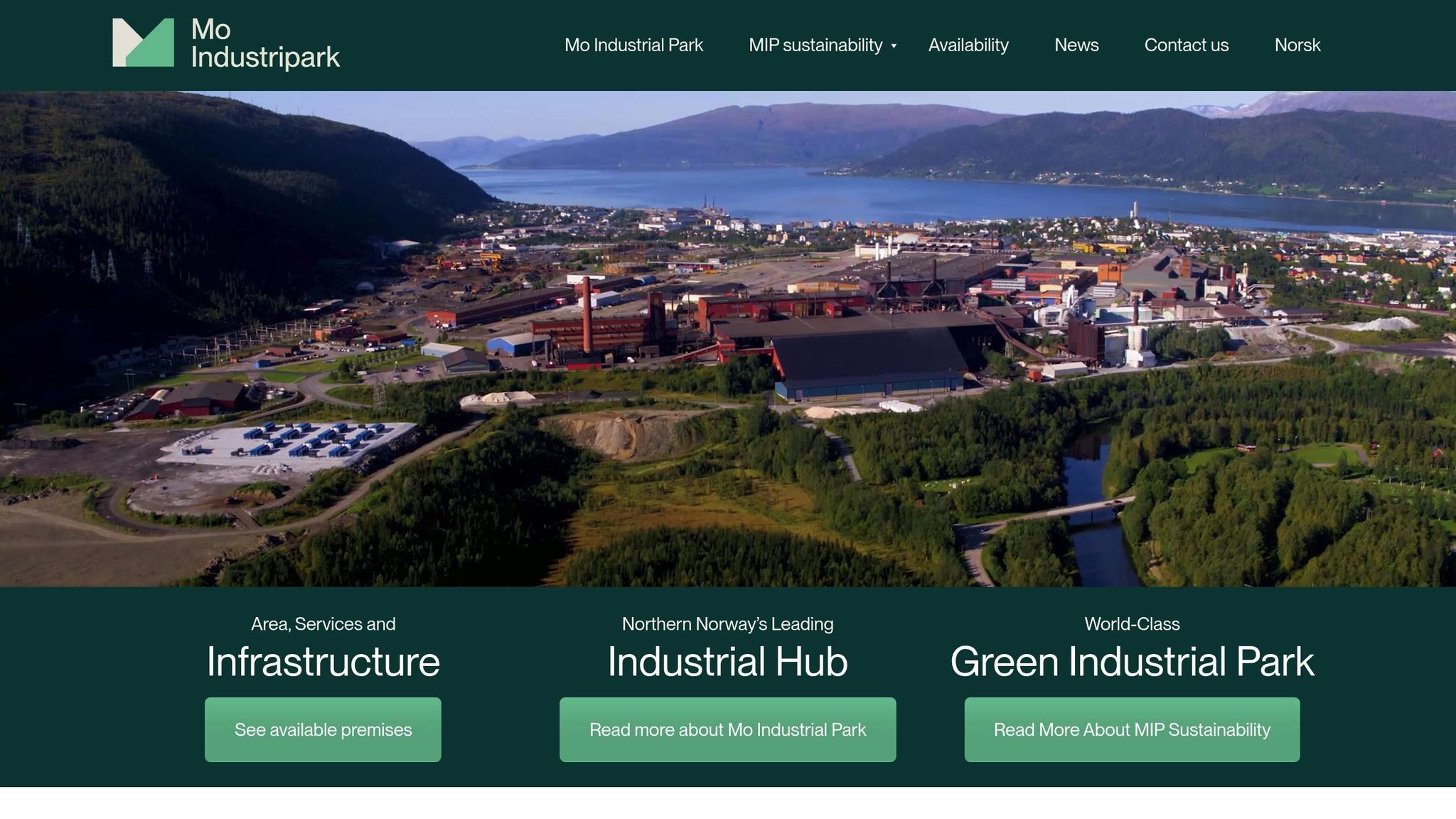

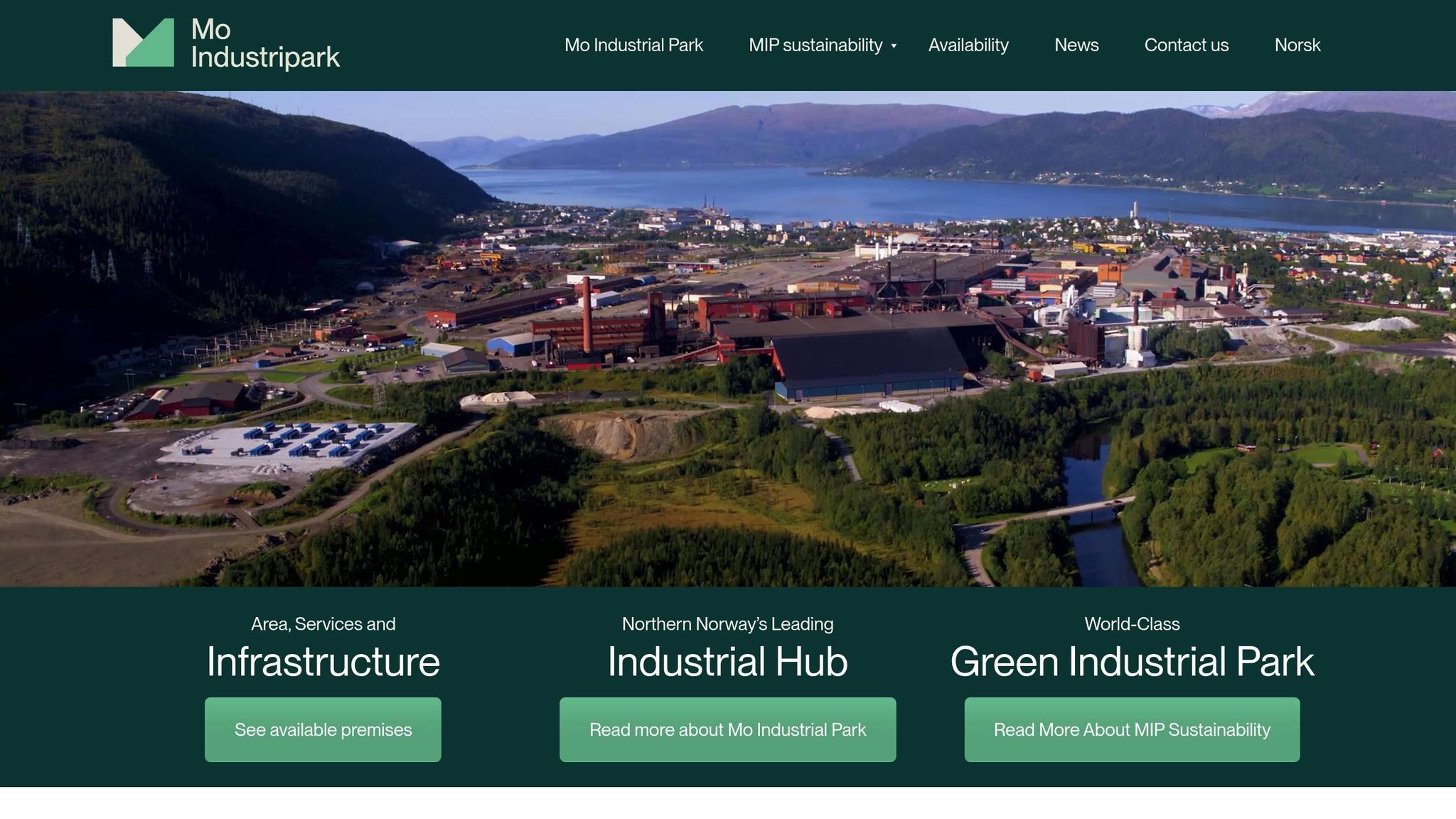

Mo Industrial Park (Norway): Powered by renewable hydropower, it recycles 400 GWh of energy annually and supports 110 companies with shared infrastructure.

Amata Industrial Park (Vietnam): Implements water and waste recycling systems, cutting fresh water demand by 40% and achieving high compliance with international standards.

Cleantech Park (Singapore): Combines renewable energy, efficient resource use, and academic partnerships, reducing energy consumption by up to 45% through innovative systems.

These parks demonstrate how shared resources and collaboration can drive efficiency while addressing global challenges like resource scarcity and emissions through sustainability consulting and strategic collaboration.

Quick Comparison

Eco-Industrial Park | Key Features | Annual Savings/Impact | Focus Areas |

|---|---|---|---|

East London (South Africa) | Jobs: 3,945; renewable energy integration; industrial symbiosis | Cost savings through shared infrastructure | Automotive, energy, ICT |

Kalundborg (Denmark) | 50+ resource exchanges; CO₂ reduction: 586,000 tons; $72–$87M savings | CO₂-neutral energy supply | Pharmaceuticals, energy, fertilizers |

Mo Park (Norway) | Hydropower; energy recycling: 400 GWh; waterworks handle 91M cubic meters | Supports 110 companies | Energy, water, logistics |

Amata (Vietnam) | Water recycling: 40%; plastic waste converted to roads; floating solar installations | High compliance with global standards | Waste management, renewable energy |

Cleantech Park (Singapore) | Solar energy; stormwater reuse; academic partnerships | Energy savings: 45% | Clean energy, manufacturing |

These examples show how EIPs combine resource-sharing and collaboration to enhance efficiency and reduce costs while addressing modern global challenges.

Top 5 Eco-Industrial Parks: Key Metrics and Environmental Impact Comparison

Eco-industrial park initiative for sustainable industrial zones in Vietnam (2014-2019)

1. East London Industrial Development Zone (ELIDZ), South Africa

In the Eastern Cape of South Africa, the East London Industrial Development Zone (ELIDZ) earned recognition as UNIDO's leading eco-industrial park in March 2024 [8]. Spanning 400 hectares (988 acres), this zone has drawn over R7.7 billion in private sector investment (roughly $420 million) and supports more than 3,945 active jobs across 40+ operational companies [15, 16].

Resource Efficiency and Waste Minimization

ELIDZ is selective about its tenants, requiring manufacturers to meet strict environmental standards [5]. Companies with operations that could be harmful to the environment must undergo a rigorous application process before being considered. The park operates under an Environmental Management Framework (EMF), which outlines development guidelines and continuously tracks environmental performance.

As a pilot site for UNIDO's Global Eco-Industrial Park Programme (GEIPP), ELIDZ adopts cleaner production practices and maximizes resource efficiency through specialized technical programs [14, 16]. Tenant businesses can also benefit from Resource Efficient and Cleaner Production (RECP) assessments, which help identify ways to cut costs while reducing resource use.

Industrial Symbiosis and Collaboration

ELIDZ actively promotes industrial symbiosis, encouraging tenant companies to exchange materials, energy, water, and by-products [14, 9]. This collaborative approach is supported by shared infrastructure, enabling businesses to reduce costs and achieve operational efficiencies.

The ELIDZ Science and Technology Park (STP) serves as a hub for innovation, facilitating technology transfer and industrial research. It includes a Centre of Excellence for Renewable Energy and provides advanced tooling and engineering services to enhance competitiveness. Key industries in the zone include automotive manufacturing - supported by an Automotive Supplier Park - renewable energy, ICT, and professional technical services [7].

Renewable Energy Integration

Through the Sustainable Energy Systems for Industrial Development (SESID) project (2023–2027), ELIDZ is rolling out low-carbon energy solutions, aiming to generate more renewable energy than it consumes [6]. Dr. Chris Ettmayr, Renewable Energy & ICT Manager, commented:

"This acknowledgement fuels our determination to continuously improve and strive to exceed compliance requirements by adopting best practices and industry standards. Our goal is to reduce carbon emissions, minimise waste generation and increase the use of renewable energy sources." [8]

Economic and Environmental Benefits

ELIDZ operates on three key principles: environmental stewardship, economic advancement, and social responsibility [8]. By driving industrial diversification in the Eastern Cape, the zone has reshaped the region’s manufacturing landscape while creating new economic opportunities for local communities [4]. Its success serves as a global model for eco-industrial parks, paving the way for similar initiatives worldwide.

2. Kalundborg Symbiosis, Denmark

Kalundborg, Denmark, is home to the world's longest-running eco-industrial network, a model of industrial collaboration built on a straightforward yet powerful idea: one company's waste becomes another's resource. This self-sustaining circular system operates without a central authority and connects 12 public and private companies, including pharmaceutical leaders Novo Nordisk and Novozymes, and energy company Equinor (formerly Statoil) [7, 8, 18, 20]. The seamless exchange of resources among these entities serves as a cornerstone of this groundbreaking industrial partnership.

Industrial Symbiosis and Cross-Industry Collaboration

The network is a testament to the efficiency of circular principles, with over 50 resource exchange processes that manage around 30 different materials, such as steam, ash, ethanol, and biomass [8, 20]. "The primary driver is to reduce production costs while ensuring resource security", says Mette Skovbjerg, Head of the Symbiosis Center [3].

Proximity plays a key role in the network's success. For instance, the power station supplies steam to Novo Nordisk and Novozymes for cleaning purposes and to the local refinery, while Equinor converts waste sulfur and nitrogen into fertilizers and recycles used water back to the power station. These exchanges, built on mutual trust, have naturally paved the way for new partnerships over time [8, 17].

Resource Efficiency and Renewable Energy Integration

The collaboration has led to significant environmental achievements. By using surface water from Lake Tissø instead of groundwater, the network saves 4 million cubic meters (1.06 billion gallons) of groundwater annually [9]. Additionally, a 10 MW heat pump facility - one of the largest in Denmark - recovers heat from wastewater, raising the heating water temperature from 131°F to 176°F [2]. These efforts have made the local energy supply CO₂ neutral, with surplus industrial heat sufficient to warm over 40,000 households [9].

Economic and Environmental Benefits

The measurable impacts of Kalundborg Symbiosis are impressive. The network saves 586,000 tons of CO₂ annually, recycles 62,000 tons of residual materials each year, and has reduced CO₂ emissions by 80% since 2015 [9]. Companies involved benefit financially as well, with annual savings estimated between $72–$87 million due to lower costs and secure resource access [3]. One standout process recovers over 99% of NMP (N-Methyl-2-pyrrolidone), reducing the carbon footprint by 1.6 tons of CO₂ per ton treated. Additionally, wastewater is repurposed for algae cultivation, producing materials for fish feed and even medical applications [17, 8].

3. Mo Industrial Park (MIP), Norway

Nestled in Northern Norway, Mo Industrial Park (MIP) is home to 110 companies employing 2,900 people. Together, these businesses generate an impressive annual turnover of NOK 15.2 billion ($1.4 billion), with NOK 9.4 billion ($870 million) coming from exports [11]. The park's centralized management of energy, water, and data networks allows tenants to concentrate on their core activities. By utilizing shared infrastructure, MIP demonstrates how economic and environmental goals can align.

Industrial Symbiosis and Collaboration Across Industries

Mo Industripark AS, the organization managing the park, provides essential services like energy, gas, water, logistics, and data management. This approach not only reduces costs for individual companies but also encourages collaboration through joint tenders and networking opportunities. Partnerships with local academic institutions further promote innovation, particularly in advancing circular industrial practices [10].

Renewable Energy at the Core

MIP takes full advantage of the Rana region's rich hydropower resources, offering tenants access to renewable energy. The park distributes 2,200 GWh of electricity annually, accounting for 1.5% to 2.0% of Norway's total electricity consumption. Additionally, it recycles over 400 GWh of energy each year - enough to power 25,000 Norwegian homes. This system captures surplus heat from industrial processes and redistributes it among tenants, significantly boosting energy efficiency [11].

Optimizing Resources for Economic Gains

MIP operates Norway's second-largest waterworks, handling over 91 million cubic meters (approximately 24 billion gallons) of water annually. This shared water system eliminates the need for individual water infrastructure, reducing costs for tenants. With support from organizations like Helgeland Knowledge Park and Rana Development, the park has become a hub for resource optimization. Spanning 300 hectares and 350,000 square meters of built space, its layout encourages close collaboration among businesses, further enhancing efficiency and innovation [11].

4. Amata Industrial Park, Vietnam

Located in Bien Hoa, Vietnam, Amata Industrial Park serves as a pilot for the Eco-Industrial Park model. Spanning 1.97 square miles (5.1 km²), this initiative was chosen by Vietnam's Ministry of Planning and Investment alongside UNIDO to lead a significant transformation. Between 2020 and 2024, compliance with international standards at the park increased from 41% to 86% [13]. Below, we explore its resource management strategies, industrial collaboration efforts, and renewable energy advancements.

Resource Efficiency and Waste Minimization

Amata Industrial Park operates on the principles of "Reduce, Reuse, and Recycle" to manage resources and cut waste. Its wastewater treatment plants process 35,700 cubic meters (9.4 million gallons) daily, amounting to an annual total of 13 million cubic meters (3.4 billion gallons) [14]. A Reverse Osmosis filtration system reclaims water for industrial use, green space irrigation, and cooling power plants, reducing fresh water demand by as much as 40% [14]. As Mr. Chuchat Saitin, Managing Director of AMATA Water Company Limited, puts it:

Our water management principles are based on a circular economy system with an efficient use of natural resources, known as the 3 R's: Reduce, Reuse and Recycle [14].

The park's waste management system achieves outstanding results. At Amata City Chonburi, for instance, only 0.06% of waste ends up in landfills [14]. Non-recyclable solid waste is converted into refuse-derived fuel for cement kilns, while a digital platform, the "Koom Kah Smart Manifest", simplifies waste collection and promotes recycling. In a notable project from October 2018, Amata collaborated with Dow Thailand Group and Siam Cement Group (SCG) to create recycled plastic roads. This effort repurposed 16.89 tons of plastic waste into 1,990 meters (6,529 feet) of asphalt road [14].

Industrial Symbiosis and Cross-Industry Collaboration

Through the Global Eco-Industrial Parks Program (GEIPP), funded by the Swiss State Secretariat for Economic Affairs (SECO), Amata has helped 18 tenant businesses - including Fleming, Shiseido, Saitex, Brother, and Toshiba - adopt cleaner production techniques and energy-efficient practices [15]. The park's licensing process enforces a closed-loop supply chain, ensuring that one company’s waste becomes raw material for another [15].

Renewable Energy Integration

Amata is also advancing renewable energy use by incorporating floating solar installations, which add 2,152 kWp of capacity to power its water treatment facilities [14]. These solar projects align with the park’s Green Energy goals, attracting international investment while addressing climate challenges. Additionally, its advanced wastewater treatment plants, equipped with online monitoring systems, ensure that no untreated water enters public canals or natural watersheds [14][16].

5. Cleantech Park, Singapore

Spanning 123.5 acres in Singapore's Jurong Innovation District, Cleantech Park stands as the country's first eco-business park and a hub for sustainable manufacturing initiatives [18]. Developed by JTC Corporation in collaboration with the Singapore Economic Development Board, the park gained recognition in November 2012 as the first in Singapore to receive the BCA Platinum Green Mark for Districts Award [19]. At its core is the $90 million CleanTech One complex, home to over 22 organizations, including DHI Water and Environment from Denmark, Toray Industries from Japan, and Sinomem Technology from China [17]. The park’s design emphasizes resource efficiency, collaboration, and renewable energy solutions, creating a forward-thinking environment for innovation.

Resource Efficiency and Waste Reduction

Cleantech Park’s infrastructure is designed to minimize resource use. At CleanTech One, a low voltage direct current (LVDC) grid - tested by NTU's Energy Research Institute and Royal Philips Electronics in early 2013 - manages LED lighting, cutting energy consumption by up to 45% [18]. The "Sky Trellis", a landscaped trellis garden, helps lower ambient temperatures and reduces the need for air conditioning. Meanwhile, a "blue network" of streams and bioswales collects approximately 150,000 liters of stormwater annually, which is reused for sanitary flushing, reducing potable water consumption by 25% [19]. These measures not only conserve resources but also establish a strong foundation for industrial collaboration within the park.

Collaboration Across Industries and Academia

Situated near Nanyang Technological University, Cleantech Park fosters a dynamic ecosystem where academic research and industrial innovation intersect. It hosts institutions like the Solar Energy Research Institute of Singapore (SERIS) and the Advanced Remanufacturing and Technology Centre (ARTC), encouraging knowledge exchange between researchers and manufacturers [19]. Associate Professor Tan Soon Keat, Deputy Executive Director of NEWRI, highlights this collaborative spirit:

"CleanTech One is about creating opportunity. We do not know whom we may run into in the elevator. It could be someone with the solution to a problem that we have had for some time." [18]

Additionally, CleanTech Two offers 240,000 square feet of specialized workshop space to support research, prototyping, and the transition of concepts into commercially viable manufacturing [17].

Embracing Renewable Energy Solutions

Cleantech Park also integrates renewable energy to reduce utility costs and promote sustainability. Solar panels installed across CleanTech One, Two, and Three generate clean energy for the park, while a district-level energy monitoring system ensures real-time optimization of consumption [19]. In early 2013, Real Time Engineering tested a 1-megawatt hydrogen fuel cell system at CleanTech One, providing clean energy to over 20% of the common areas [18]. Together with energy-efficient infrastructure, these renewable energy initiatives contribute to an estimated 40% reduction in annual utility costs. By 2012, CleanTech One achieved 70% occupancy, attracting global clean energy leaders like Yingli Solar [19].

Key Metrics Comparison

The performance metrics of these parks provide a closer look at their tangible impacts. Kalundborg Symbiosis stands out with its measurable achievements in resource efficiency and cost reduction. This industrial symbiosis network facilitates around 50 different exchange processes involving 30 types of materials - such as steam, water, ash, gypsum, and biomass - among 12 public and private entities. These exchanges lead to a reduction of 270,000 tons of CO₂ emissions annually and yield cost savings estimated between $72 million and $87 million each year[3].

Mette Skovbjerg, Head of the Symbiosis Center, highlights the practical motivations behind these collaborations:

The driver for this type of collaboration is actually to reduce production costs, not CO₂ emissions. The real issue is to achieve primary goals companies have; to secure supplies and access to resources.[3]

This pragmatic approach allows companies to reimagine waste as a resource, turning potential liabilities into valuable assets.

While Kalundborg sets a high benchmark, other eco-industrial parks are adopting frameworks developed by organizations like UNIDO and the World Bank. However, their data is often less comprehensive. Globally, the growth of eco-industrial parks is accelerating, with more than 55.9% of the world’s 438 parks established since 2001. This trend reflects the increasing adoption of circular economy models worldwide[21].

Parks with a long history, like Kalundborg, demonstrate the most quantifiable benefits, offering a blueprint for success. In contrast, newer parks show promise but often lack detailed metrics to fully capture their impact. The ability to foster deep industrial symbiosis remains crucial for achieving both economic and environmental progress.

Conclusion

These five parks showcase how prioritizing cost savings, resource efficiency, and risk management can lead to thriving circular economy models. Peter Laybourn, CEO of International Synergies, encapsulates this approach perfectly:

We use the language of business. We don't talk about emissions, we talk about risks and profit. But it just so happens... we end up getting the environmental benefits as well. [3]

The global rise in adoption, from 245 parks in 2001 to 438 in 2020[22], reflects a growing industry commitment to these principles. Achieving success in this space hinges on having dedicated park operators who can effectively manage the intricate flows of materials, nurture trust among companies, and establish the legal frameworks necessary for resource sharing[22]. Without this essential coordination, even the best-intentioned symbiosis efforts face challenges in scaling. This upward trend highlights the importance of actionable and well-structured strategies.

To put these strategies into practice, begin by identifying existing waste streams that currently incur disposal costs but could serve as valuable inputs for other processes. Tools like the UNIDO EIP Toolbox can help pinpoint symbiosis opportunities and funding sources[20]. Focus on exchanges involving non-sensitive materials - such as steam, wastewater, ash, and gypsum - where companies can realize immediate benefits without compromising proprietary information[12].

Advancements in digital platforms now allow real-time tracking of energy, water, and material flows[22], while incentives like tax credits and simplified permitting processes further lower barriers to implementation[1].

These examples prove that industrial symbiosis is not only feasible but also delivers tangible financial and operational returns. They reinforce the article's central message: profitability and sustainability go hand in hand. The framework is proven - the challenge lies in how quickly these strategies can be adapted and applied at a local level.

FAQs

How do eco-industrial parks improve resource efficiency?

Eco-industrial parks (EIPs) improve how resources are used by applying industrial symbiosis - a system where one company’s waste or byproducts become valuable inputs for another. This setup minimizes the demand for new resources by creating a circular exchange of materials, energy, and water within the park. For example, surplus heat, steam, or electricity produced by one facility can be redirected to nearby businesses, reducing both waste and expenses.

A standout example is the Kalundborg Symbiosis in Denmark. Here, wastewater from biotech companies is heated and integrated into a district heating system. This process raises water temperatures from 55°F to 80°F, eliminating the need for fossil-fuel-based heating in the community. Advanced technologies like energy-sharing platforms, real-time energy mapping, and shared infrastructure further streamline these exchanges, creating an efficient closed-loop system. These approaches not only cut environmental impact but also help manufacturers achieve sustainable and profitable growth, both in the United States and globally.

What are the key benefits of industrial symbiosis in eco-industrial parks?

Industrial symbiosis transforms waste from one company into a resource for another, delivering benefits across economic, environmental, and social dimensions. By sharing resources such as surplus heat, steam, water, or by-products, businesses can significantly cut operating expenses, boost efficiency, and lower energy consumption. A prime example is Kalundborg, Denmark, where waste heat from a power plant is used for district heating, reducing both fuel costs and energy use.

From an environmental perspective, this approach reduces waste and curbs greenhouse gas emissions by turning potential pollutants into useful inputs. This not only aligns with sustainability objectives but also generates measurable cost savings and efficiency improvements.

On a broader community level, industrial symbiosis encourages collaboration among businesses, service providers, and local governments, fostering regional growth and strengthening social ties. Organizations like Council Fire assist companies in adopting these strategies, blending financial success with environmental responsibility and community engagement.

How do eco-industrial parks help lower carbon emissions?

Eco-industrial parks are reshaping how industries manage resources and energy, offering a practical way to cut carbon emissions. These parks operate on the principle of turning waste into valuable resources. For instance, businesses within these parks can share by-products like waste heat, steam, or materials such as gypsum. This approach allows companies to replace traditional fossil fuels with recovered energy or renewable sources, leading to significant reductions in CO₂ emissions. A prime example is Denmark’s Kalundborg Symbiosis, where businesses collaborate to redirect resources like steam and ash, achieving impressive carbon savings.

Another advantage of eco-industrial parks is their ability to reduce emissions tied to transportation and raw material extraction. By clustering industries with complementary needs, they lower the reliance on long-distance shipping and cut fuel consumption. This model is particularly impactful in countries like China, where industrial parks are a significant source of energy use and greenhouse gas emissions. By adopting clean production methods and embracing circular economy principles, these parks are paving the way for more sustainable industrial systems. Council Fire plays a key role in helping organizations implement these strategies, ensuring they balance environmental progress with economic viability.

Related Blog Posts

Latest Articles

©2025

FAQ

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Jan 3, 2026

Top 5 Manufacturing Eco-Industrial Parks Worldwide

Sustainability Strategy

In This Article

Shared energy, water and waste systems in eco-industrial parks show how industrial symbiosis and renewables cut costs, save resources, and lower emissions.

Top 5 Manufacturing Eco-Industrial Parks Worldwide

Eco-Industrial Parks (EIPs) are transforming manufacturing by turning waste into resources, cutting costs, and reducing environmental impact. These parks integrate businesses to share resources like energy, water, and waste systems, creating efficient and collaborative ecosystems. Here are five leading examples:

East London Industrial Development Zone (South Africa): Focuses on resource efficiency, industrial symbiosis, and renewable energy, generating over 3,945 jobs and saving costs through shared infrastructure.

Kalundborg Symbiosis (Denmark): A pioneer in industrial symbiosis, saving 586,000 tons of CO₂ annually and achieving $72–$87 million in yearly savings by reusing resources across 12 businesses.

Mo Industrial Park (Norway): Powered by renewable hydropower, it recycles 400 GWh of energy annually and supports 110 companies with shared infrastructure.

Amata Industrial Park (Vietnam): Implements water and waste recycling systems, cutting fresh water demand by 40% and achieving high compliance with international standards.

Cleantech Park (Singapore): Combines renewable energy, efficient resource use, and academic partnerships, reducing energy consumption by up to 45% through innovative systems.

These parks demonstrate how shared resources and collaboration can drive efficiency while addressing global challenges like resource scarcity and emissions through sustainability consulting and strategic collaboration.

Quick Comparison

Eco-Industrial Park | Key Features | Annual Savings/Impact | Focus Areas |

|---|---|---|---|

East London (South Africa) | Jobs: 3,945; renewable energy integration; industrial symbiosis | Cost savings through shared infrastructure | Automotive, energy, ICT |

Kalundborg (Denmark) | 50+ resource exchanges; CO₂ reduction: 586,000 tons; $72–$87M savings | CO₂-neutral energy supply | Pharmaceuticals, energy, fertilizers |

Mo Park (Norway) | Hydropower; energy recycling: 400 GWh; waterworks handle 91M cubic meters | Supports 110 companies | Energy, water, logistics |

Amata (Vietnam) | Water recycling: 40%; plastic waste converted to roads; floating solar installations | High compliance with global standards | Waste management, renewable energy |

Cleantech Park (Singapore) | Solar energy; stormwater reuse; academic partnerships | Energy savings: 45% | Clean energy, manufacturing |

These examples show how EIPs combine resource-sharing and collaboration to enhance efficiency and reduce costs while addressing modern global challenges.

Top 5 Eco-Industrial Parks: Key Metrics and Environmental Impact Comparison

Eco-industrial park initiative for sustainable industrial zones in Vietnam (2014-2019)

1. East London Industrial Development Zone (ELIDZ), South Africa

In the Eastern Cape of South Africa, the East London Industrial Development Zone (ELIDZ) earned recognition as UNIDO's leading eco-industrial park in March 2024 [8]. Spanning 400 hectares (988 acres), this zone has drawn over R7.7 billion in private sector investment (roughly $420 million) and supports more than 3,945 active jobs across 40+ operational companies [15, 16].

Resource Efficiency and Waste Minimization

ELIDZ is selective about its tenants, requiring manufacturers to meet strict environmental standards [5]. Companies with operations that could be harmful to the environment must undergo a rigorous application process before being considered. The park operates under an Environmental Management Framework (EMF), which outlines development guidelines and continuously tracks environmental performance.

As a pilot site for UNIDO's Global Eco-Industrial Park Programme (GEIPP), ELIDZ adopts cleaner production practices and maximizes resource efficiency through specialized technical programs [14, 16]. Tenant businesses can also benefit from Resource Efficient and Cleaner Production (RECP) assessments, which help identify ways to cut costs while reducing resource use.

Industrial Symbiosis and Collaboration

ELIDZ actively promotes industrial symbiosis, encouraging tenant companies to exchange materials, energy, water, and by-products [14, 9]. This collaborative approach is supported by shared infrastructure, enabling businesses to reduce costs and achieve operational efficiencies.

The ELIDZ Science and Technology Park (STP) serves as a hub for innovation, facilitating technology transfer and industrial research. It includes a Centre of Excellence for Renewable Energy and provides advanced tooling and engineering services to enhance competitiveness. Key industries in the zone include automotive manufacturing - supported by an Automotive Supplier Park - renewable energy, ICT, and professional technical services [7].

Renewable Energy Integration

Through the Sustainable Energy Systems for Industrial Development (SESID) project (2023–2027), ELIDZ is rolling out low-carbon energy solutions, aiming to generate more renewable energy than it consumes [6]. Dr. Chris Ettmayr, Renewable Energy & ICT Manager, commented:

"This acknowledgement fuels our determination to continuously improve and strive to exceed compliance requirements by adopting best practices and industry standards. Our goal is to reduce carbon emissions, minimise waste generation and increase the use of renewable energy sources." [8]

Economic and Environmental Benefits

ELIDZ operates on three key principles: environmental stewardship, economic advancement, and social responsibility [8]. By driving industrial diversification in the Eastern Cape, the zone has reshaped the region’s manufacturing landscape while creating new economic opportunities for local communities [4]. Its success serves as a global model for eco-industrial parks, paving the way for similar initiatives worldwide.

2. Kalundborg Symbiosis, Denmark

Kalundborg, Denmark, is home to the world's longest-running eco-industrial network, a model of industrial collaboration built on a straightforward yet powerful idea: one company's waste becomes another's resource. This self-sustaining circular system operates without a central authority and connects 12 public and private companies, including pharmaceutical leaders Novo Nordisk and Novozymes, and energy company Equinor (formerly Statoil) [7, 8, 18, 20]. The seamless exchange of resources among these entities serves as a cornerstone of this groundbreaking industrial partnership.

Industrial Symbiosis and Cross-Industry Collaboration

The network is a testament to the efficiency of circular principles, with over 50 resource exchange processes that manage around 30 different materials, such as steam, ash, ethanol, and biomass [8, 20]. "The primary driver is to reduce production costs while ensuring resource security", says Mette Skovbjerg, Head of the Symbiosis Center [3].

Proximity plays a key role in the network's success. For instance, the power station supplies steam to Novo Nordisk and Novozymes for cleaning purposes and to the local refinery, while Equinor converts waste sulfur and nitrogen into fertilizers and recycles used water back to the power station. These exchanges, built on mutual trust, have naturally paved the way for new partnerships over time [8, 17].

Resource Efficiency and Renewable Energy Integration

The collaboration has led to significant environmental achievements. By using surface water from Lake Tissø instead of groundwater, the network saves 4 million cubic meters (1.06 billion gallons) of groundwater annually [9]. Additionally, a 10 MW heat pump facility - one of the largest in Denmark - recovers heat from wastewater, raising the heating water temperature from 131°F to 176°F [2]. These efforts have made the local energy supply CO₂ neutral, with surplus industrial heat sufficient to warm over 40,000 households [9].

Economic and Environmental Benefits

The measurable impacts of Kalundborg Symbiosis are impressive. The network saves 586,000 tons of CO₂ annually, recycles 62,000 tons of residual materials each year, and has reduced CO₂ emissions by 80% since 2015 [9]. Companies involved benefit financially as well, with annual savings estimated between $72–$87 million due to lower costs and secure resource access [3]. One standout process recovers over 99% of NMP (N-Methyl-2-pyrrolidone), reducing the carbon footprint by 1.6 tons of CO₂ per ton treated. Additionally, wastewater is repurposed for algae cultivation, producing materials for fish feed and even medical applications [17, 8].

3. Mo Industrial Park (MIP), Norway

Nestled in Northern Norway, Mo Industrial Park (MIP) is home to 110 companies employing 2,900 people. Together, these businesses generate an impressive annual turnover of NOK 15.2 billion ($1.4 billion), with NOK 9.4 billion ($870 million) coming from exports [11]. The park's centralized management of energy, water, and data networks allows tenants to concentrate on their core activities. By utilizing shared infrastructure, MIP demonstrates how economic and environmental goals can align.

Industrial Symbiosis and Collaboration Across Industries

Mo Industripark AS, the organization managing the park, provides essential services like energy, gas, water, logistics, and data management. This approach not only reduces costs for individual companies but also encourages collaboration through joint tenders and networking opportunities. Partnerships with local academic institutions further promote innovation, particularly in advancing circular industrial practices [10].

Renewable Energy at the Core

MIP takes full advantage of the Rana region's rich hydropower resources, offering tenants access to renewable energy. The park distributes 2,200 GWh of electricity annually, accounting for 1.5% to 2.0% of Norway's total electricity consumption. Additionally, it recycles over 400 GWh of energy each year - enough to power 25,000 Norwegian homes. This system captures surplus heat from industrial processes and redistributes it among tenants, significantly boosting energy efficiency [11].

Optimizing Resources for Economic Gains

MIP operates Norway's second-largest waterworks, handling over 91 million cubic meters (approximately 24 billion gallons) of water annually. This shared water system eliminates the need for individual water infrastructure, reducing costs for tenants. With support from organizations like Helgeland Knowledge Park and Rana Development, the park has become a hub for resource optimization. Spanning 300 hectares and 350,000 square meters of built space, its layout encourages close collaboration among businesses, further enhancing efficiency and innovation [11].

4. Amata Industrial Park, Vietnam

Located in Bien Hoa, Vietnam, Amata Industrial Park serves as a pilot for the Eco-Industrial Park model. Spanning 1.97 square miles (5.1 km²), this initiative was chosen by Vietnam's Ministry of Planning and Investment alongside UNIDO to lead a significant transformation. Between 2020 and 2024, compliance with international standards at the park increased from 41% to 86% [13]. Below, we explore its resource management strategies, industrial collaboration efforts, and renewable energy advancements.

Resource Efficiency and Waste Minimization

Amata Industrial Park operates on the principles of "Reduce, Reuse, and Recycle" to manage resources and cut waste. Its wastewater treatment plants process 35,700 cubic meters (9.4 million gallons) daily, amounting to an annual total of 13 million cubic meters (3.4 billion gallons) [14]. A Reverse Osmosis filtration system reclaims water for industrial use, green space irrigation, and cooling power plants, reducing fresh water demand by as much as 40% [14]. As Mr. Chuchat Saitin, Managing Director of AMATA Water Company Limited, puts it:

Our water management principles are based on a circular economy system with an efficient use of natural resources, known as the 3 R's: Reduce, Reuse and Recycle [14].

The park's waste management system achieves outstanding results. At Amata City Chonburi, for instance, only 0.06% of waste ends up in landfills [14]. Non-recyclable solid waste is converted into refuse-derived fuel for cement kilns, while a digital platform, the "Koom Kah Smart Manifest", simplifies waste collection and promotes recycling. In a notable project from October 2018, Amata collaborated with Dow Thailand Group and Siam Cement Group (SCG) to create recycled plastic roads. This effort repurposed 16.89 tons of plastic waste into 1,990 meters (6,529 feet) of asphalt road [14].

Industrial Symbiosis and Cross-Industry Collaboration

Through the Global Eco-Industrial Parks Program (GEIPP), funded by the Swiss State Secretariat for Economic Affairs (SECO), Amata has helped 18 tenant businesses - including Fleming, Shiseido, Saitex, Brother, and Toshiba - adopt cleaner production techniques and energy-efficient practices [15]. The park's licensing process enforces a closed-loop supply chain, ensuring that one company’s waste becomes raw material for another [15].

Renewable Energy Integration

Amata is also advancing renewable energy use by incorporating floating solar installations, which add 2,152 kWp of capacity to power its water treatment facilities [14]. These solar projects align with the park’s Green Energy goals, attracting international investment while addressing climate challenges. Additionally, its advanced wastewater treatment plants, equipped with online monitoring systems, ensure that no untreated water enters public canals or natural watersheds [14][16].

5. Cleantech Park, Singapore

Spanning 123.5 acres in Singapore's Jurong Innovation District, Cleantech Park stands as the country's first eco-business park and a hub for sustainable manufacturing initiatives [18]. Developed by JTC Corporation in collaboration with the Singapore Economic Development Board, the park gained recognition in November 2012 as the first in Singapore to receive the BCA Platinum Green Mark for Districts Award [19]. At its core is the $90 million CleanTech One complex, home to over 22 organizations, including DHI Water and Environment from Denmark, Toray Industries from Japan, and Sinomem Technology from China [17]. The park’s design emphasizes resource efficiency, collaboration, and renewable energy solutions, creating a forward-thinking environment for innovation.

Resource Efficiency and Waste Reduction

Cleantech Park’s infrastructure is designed to minimize resource use. At CleanTech One, a low voltage direct current (LVDC) grid - tested by NTU's Energy Research Institute and Royal Philips Electronics in early 2013 - manages LED lighting, cutting energy consumption by up to 45% [18]. The "Sky Trellis", a landscaped trellis garden, helps lower ambient temperatures and reduces the need for air conditioning. Meanwhile, a "blue network" of streams and bioswales collects approximately 150,000 liters of stormwater annually, which is reused for sanitary flushing, reducing potable water consumption by 25% [19]. These measures not only conserve resources but also establish a strong foundation for industrial collaboration within the park.

Collaboration Across Industries and Academia

Situated near Nanyang Technological University, Cleantech Park fosters a dynamic ecosystem where academic research and industrial innovation intersect. It hosts institutions like the Solar Energy Research Institute of Singapore (SERIS) and the Advanced Remanufacturing and Technology Centre (ARTC), encouraging knowledge exchange between researchers and manufacturers [19]. Associate Professor Tan Soon Keat, Deputy Executive Director of NEWRI, highlights this collaborative spirit:

"CleanTech One is about creating opportunity. We do not know whom we may run into in the elevator. It could be someone with the solution to a problem that we have had for some time." [18]

Additionally, CleanTech Two offers 240,000 square feet of specialized workshop space to support research, prototyping, and the transition of concepts into commercially viable manufacturing [17].

Embracing Renewable Energy Solutions

Cleantech Park also integrates renewable energy to reduce utility costs and promote sustainability. Solar panels installed across CleanTech One, Two, and Three generate clean energy for the park, while a district-level energy monitoring system ensures real-time optimization of consumption [19]. In early 2013, Real Time Engineering tested a 1-megawatt hydrogen fuel cell system at CleanTech One, providing clean energy to over 20% of the common areas [18]. Together with energy-efficient infrastructure, these renewable energy initiatives contribute to an estimated 40% reduction in annual utility costs. By 2012, CleanTech One achieved 70% occupancy, attracting global clean energy leaders like Yingli Solar [19].

Key Metrics Comparison

The performance metrics of these parks provide a closer look at their tangible impacts. Kalundborg Symbiosis stands out with its measurable achievements in resource efficiency and cost reduction. This industrial symbiosis network facilitates around 50 different exchange processes involving 30 types of materials - such as steam, water, ash, gypsum, and biomass - among 12 public and private entities. These exchanges lead to a reduction of 270,000 tons of CO₂ emissions annually and yield cost savings estimated between $72 million and $87 million each year[3].

Mette Skovbjerg, Head of the Symbiosis Center, highlights the practical motivations behind these collaborations:

The driver for this type of collaboration is actually to reduce production costs, not CO₂ emissions. The real issue is to achieve primary goals companies have; to secure supplies and access to resources.[3]

This pragmatic approach allows companies to reimagine waste as a resource, turning potential liabilities into valuable assets.

While Kalundborg sets a high benchmark, other eco-industrial parks are adopting frameworks developed by organizations like UNIDO and the World Bank. However, their data is often less comprehensive. Globally, the growth of eco-industrial parks is accelerating, with more than 55.9% of the world’s 438 parks established since 2001. This trend reflects the increasing adoption of circular economy models worldwide[21].

Parks with a long history, like Kalundborg, demonstrate the most quantifiable benefits, offering a blueprint for success. In contrast, newer parks show promise but often lack detailed metrics to fully capture their impact. The ability to foster deep industrial symbiosis remains crucial for achieving both economic and environmental progress.

Conclusion

These five parks showcase how prioritizing cost savings, resource efficiency, and risk management can lead to thriving circular economy models. Peter Laybourn, CEO of International Synergies, encapsulates this approach perfectly:

We use the language of business. We don't talk about emissions, we talk about risks and profit. But it just so happens... we end up getting the environmental benefits as well. [3]

The global rise in adoption, from 245 parks in 2001 to 438 in 2020[22], reflects a growing industry commitment to these principles. Achieving success in this space hinges on having dedicated park operators who can effectively manage the intricate flows of materials, nurture trust among companies, and establish the legal frameworks necessary for resource sharing[22]. Without this essential coordination, even the best-intentioned symbiosis efforts face challenges in scaling. This upward trend highlights the importance of actionable and well-structured strategies.

To put these strategies into practice, begin by identifying existing waste streams that currently incur disposal costs but could serve as valuable inputs for other processes. Tools like the UNIDO EIP Toolbox can help pinpoint symbiosis opportunities and funding sources[20]. Focus on exchanges involving non-sensitive materials - such as steam, wastewater, ash, and gypsum - where companies can realize immediate benefits without compromising proprietary information[12].

Advancements in digital platforms now allow real-time tracking of energy, water, and material flows[22], while incentives like tax credits and simplified permitting processes further lower barriers to implementation[1].

These examples prove that industrial symbiosis is not only feasible but also delivers tangible financial and operational returns. They reinforce the article's central message: profitability and sustainability go hand in hand. The framework is proven - the challenge lies in how quickly these strategies can be adapted and applied at a local level.

FAQs

How do eco-industrial parks improve resource efficiency?

Eco-industrial parks (EIPs) improve how resources are used by applying industrial symbiosis - a system where one company’s waste or byproducts become valuable inputs for another. This setup minimizes the demand for new resources by creating a circular exchange of materials, energy, and water within the park. For example, surplus heat, steam, or electricity produced by one facility can be redirected to nearby businesses, reducing both waste and expenses.

A standout example is the Kalundborg Symbiosis in Denmark. Here, wastewater from biotech companies is heated and integrated into a district heating system. This process raises water temperatures from 55°F to 80°F, eliminating the need for fossil-fuel-based heating in the community. Advanced technologies like energy-sharing platforms, real-time energy mapping, and shared infrastructure further streamline these exchanges, creating an efficient closed-loop system. These approaches not only cut environmental impact but also help manufacturers achieve sustainable and profitable growth, both in the United States and globally.

What are the key benefits of industrial symbiosis in eco-industrial parks?

Industrial symbiosis transforms waste from one company into a resource for another, delivering benefits across economic, environmental, and social dimensions. By sharing resources such as surplus heat, steam, water, or by-products, businesses can significantly cut operating expenses, boost efficiency, and lower energy consumption. A prime example is Kalundborg, Denmark, where waste heat from a power plant is used for district heating, reducing both fuel costs and energy use.

From an environmental perspective, this approach reduces waste and curbs greenhouse gas emissions by turning potential pollutants into useful inputs. This not only aligns with sustainability objectives but also generates measurable cost savings and efficiency improvements.

On a broader community level, industrial symbiosis encourages collaboration among businesses, service providers, and local governments, fostering regional growth and strengthening social ties. Organizations like Council Fire assist companies in adopting these strategies, blending financial success with environmental responsibility and community engagement.

How do eco-industrial parks help lower carbon emissions?

Eco-industrial parks are reshaping how industries manage resources and energy, offering a practical way to cut carbon emissions. These parks operate on the principle of turning waste into valuable resources. For instance, businesses within these parks can share by-products like waste heat, steam, or materials such as gypsum. This approach allows companies to replace traditional fossil fuels with recovered energy or renewable sources, leading to significant reductions in CO₂ emissions. A prime example is Denmark’s Kalundborg Symbiosis, where businesses collaborate to redirect resources like steam and ash, achieving impressive carbon savings.

Another advantage of eco-industrial parks is their ability to reduce emissions tied to transportation and raw material extraction. By clustering industries with complementary needs, they lower the reliance on long-distance shipping and cut fuel consumption. This model is particularly impactful in countries like China, where industrial parks are a significant source of energy use and greenhouse gas emissions. By adopting clean production methods and embracing circular economy principles, these parks are paving the way for more sustainable industrial systems. Council Fire plays a key role in helping organizations implement these strategies, ensuring they balance environmental progress with economic viability.

Related Blog Posts

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Jan 3, 2026

Top 5 Manufacturing Eco-Industrial Parks Worldwide

Sustainability Strategy

In This Article

Shared energy, water and waste systems in eco-industrial parks show how industrial symbiosis and renewables cut costs, save resources, and lower emissions.

Top 5 Manufacturing Eco-Industrial Parks Worldwide

Eco-Industrial Parks (EIPs) are transforming manufacturing by turning waste into resources, cutting costs, and reducing environmental impact. These parks integrate businesses to share resources like energy, water, and waste systems, creating efficient and collaborative ecosystems. Here are five leading examples:

East London Industrial Development Zone (South Africa): Focuses on resource efficiency, industrial symbiosis, and renewable energy, generating over 3,945 jobs and saving costs through shared infrastructure.

Kalundborg Symbiosis (Denmark): A pioneer in industrial symbiosis, saving 586,000 tons of CO₂ annually and achieving $72–$87 million in yearly savings by reusing resources across 12 businesses.

Mo Industrial Park (Norway): Powered by renewable hydropower, it recycles 400 GWh of energy annually and supports 110 companies with shared infrastructure.

Amata Industrial Park (Vietnam): Implements water and waste recycling systems, cutting fresh water demand by 40% and achieving high compliance with international standards.

Cleantech Park (Singapore): Combines renewable energy, efficient resource use, and academic partnerships, reducing energy consumption by up to 45% through innovative systems.

These parks demonstrate how shared resources and collaboration can drive efficiency while addressing global challenges like resource scarcity and emissions through sustainability consulting and strategic collaboration.

Quick Comparison

Eco-Industrial Park | Key Features | Annual Savings/Impact | Focus Areas |

|---|---|---|---|

East London (South Africa) | Jobs: 3,945; renewable energy integration; industrial symbiosis | Cost savings through shared infrastructure | Automotive, energy, ICT |

Kalundborg (Denmark) | 50+ resource exchanges; CO₂ reduction: 586,000 tons; $72–$87M savings | CO₂-neutral energy supply | Pharmaceuticals, energy, fertilizers |

Mo Park (Norway) | Hydropower; energy recycling: 400 GWh; waterworks handle 91M cubic meters | Supports 110 companies | Energy, water, logistics |

Amata (Vietnam) | Water recycling: 40%; plastic waste converted to roads; floating solar installations | High compliance with global standards | Waste management, renewable energy |

Cleantech Park (Singapore) | Solar energy; stormwater reuse; academic partnerships | Energy savings: 45% | Clean energy, manufacturing |

These examples show how EIPs combine resource-sharing and collaboration to enhance efficiency and reduce costs while addressing modern global challenges.

Top 5 Eco-Industrial Parks: Key Metrics and Environmental Impact Comparison

Eco-industrial park initiative for sustainable industrial zones in Vietnam (2014-2019)

1. East London Industrial Development Zone (ELIDZ), South Africa

In the Eastern Cape of South Africa, the East London Industrial Development Zone (ELIDZ) earned recognition as UNIDO's leading eco-industrial park in March 2024 [8]. Spanning 400 hectares (988 acres), this zone has drawn over R7.7 billion in private sector investment (roughly $420 million) and supports more than 3,945 active jobs across 40+ operational companies [15, 16].

Resource Efficiency and Waste Minimization

ELIDZ is selective about its tenants, requiring manufacturers to meet strict environmental standards [5]. Companies with operations that could be harmful to the environment must undergo a rigorous application process before being considered. The park operates under an Environmental Management Framework (EMF), which outlines development guidelines and continuously tracks environmental performance.

As a pilot site for UNIDO's Global Eco-Industrial Park Programme (GEIPP), ELIDZ adopts cleaner production practices and maximizes resource efficiency through specialized technical programs [14, 16]. Tenant businesses can also benefit from Resource Efficient and Cleaner Production (RECP) assessments, which help identify ways to cut costs while reducing resource use.

Industrial Symbiosis and Collaboration

ELIDZ actively promotes industrial symbiosis, encouraging tenant companies to exchange materials, energy, water, and by-products [14, 9]. This collaborative approach is supported by shared infrastructure, enabling businesses to reduce costs and achieve operational efficiencies.

The ELIDZ Science and Technology Park (STP) serves as a hub for innovation, facilitating technology transfer and industrial research. It includes a Centre of Excellence for Renewable Energy and provides advanced tooling and engineering services to enhance competitiveness. Key industries in the zone include automotive manufacturing - supported by an Automotive Supplier Park - renewable energy, ICT, and professional technical services [7].

Renewable Energy Integration

Through the Sustainable Energy Systems for Industrial Development (SESID) project (2023–2027), ELIDZ is rolling out low-carbon energy solutions, aiming to generate more renewable energy than it consumes [6]. Dr. Chris Ettmayr, Renewable Energy & ICT Manager, commented:

"This acknowledgement fuels our determination to continuously improve and strive to exceed compliance requirements by adopting best practices and industry standards. Our goal is to reduce carbon emissions, minimise waste generation and increase the use of renewable energy sources." [8]

Economic and Environmental Benefits

ELIDZ operates on three key principles: environmental stewardship, economic advancement, and social responsibility [8]. By driving industrial diversification in the Eastern Cape, the zone has reshaped the region’s manufacturing landscape while creating new economic opportunities for local communities [4]. Its success serves as a global model for eco-industrial parks, paving the way for similar initiatives worldwide.

2. Kalundborg Symbiosis, Denmark

Kalundborg, Denmark, is home to the world's longest-running eco-industrial network, a model of industrial collaboration built on a straightforward yet powerful idea: one company's waste becomes another's resource. This self-sustaining circular system operates without a central authority and connects 12 public and private companies, including pharmaceutical leaders Novo Nordisk and Novozymes, and energy company Equinor (formerly Statoil) [7, 8, 18, 20]. The seamless exchange of resources among these entities serves as a cornerstone of this groundbreaking industrial partnership.

Industrial Symbiosis and Cross-Industry Collaboration

The network is a testament to the efficiency of circular principles, with over 50 resource exchange processes that manage around 30 different materials, such as steam, ash, ethanol, and biomass [8, 20]. "The primary driver is to reduce production costs while ensuring resource security", says Mette Skovbjerg, Head of the Symbiosis Center [3].

Proximity plays a key role in the network's success. For instance, the power station supplies steam to Novo Nordisk and Novozymes for cleaning purposes and to the local refinery, while Equinor converts waste sulfur and nitrogen into fertilizers and recycles used water back to the power station. These exchanges, built on mutual trust, have naturally paved the way for new partnerships over time [8, 17].

Resource Efficiency and Renewable Energy Integration

The collaboration has led to significant environmental achievements. By using surface water from Lake Tissø instead of groundwater, the network saves 4 million cubic meters (1.06 billion gallons) of groundwater annually [9]. Additionally, a 10 MW heat pump facility - one of the largest in Denmark - recovers heat from wastewater, raising the heating water temperature from 131°F to 176°F [2]. These efforts have made the local energy supply CO₂ neutral, with surplus industrial heat sufficient to warm over 40,000 households [9].

Economic and Environmental Benefits

The measurable impacts of Kalundborg Symbiosis are impressive. The network saves 586,000 tons of CO₂ annually, recycles 62,000 tons of residual materials each year, and has reduced CO₂ emissions by 80% since 2015 [9]. Companies involved benefit financially as well, with annual savings estimated between $72–$87 million due to lower costs and secure resource access [3]. One standout process recovers over 99% of NMP (N-Methyl-2-pyrrolidone), reducing the carbon footprint by 1.6 tons of CO₂ per ton treated. Additionally, wastewater is repurposed for algae cultivation, producing materials for fish feed and even medical applications [17, 8].

3. Mo Industrial Park (MIP), Norway

Nestled in Northern Norway, Mo Industrial Park (MIP) is home to 110 companies employing 2,900 people. Together, these businesses generate an impressive annual turnover of NOK 15.2 billion ($1.4 billion), with NOK 9.4 billion ($870 million) coming from exports [11]. The park's centralized management of energy, water, and data networks allows tenants to concentrate on their core activities. By utilizing shared infrastructure, MIP demonstrates how economic and environmental goals can align.

Industrial Symbiosis and Collaboration Across Industries

Mo Industripark AS, the organization managing the park, provides essential services like energy, gas, water, logistics, and data management. This approach not only reduces costs for individual companies but also encourages collaboration through joint tenders and networking opportunities. Partnerships with local academic institutions further promote innovation, particularly in advancing circular industrial practices [10].

Renewable Energy at the Core

MIP takes full advantage of the Rana region's rich hydropower resources, offering tenants access to renewable energy. The park distributes 2,200 GWh of electricity annually, accounting for 1.5% to 2.0% of Norway's total electricity consumption. Additionally, it recycles over 400 GWh of energy each year - enough to power 25,000 Norwegian homes. This system captures surplus heat from industrial processes and redistributes it among tenants, significantly boosting energy efficiency [11].

Optimizing Resources for Economic Gains

MIP operates Norway's second-largest waterworks, handling over 91 million cubic meters (approximately 24 billion gallons) of water annually. This shared water system eliminates the need for individual water infrastructure, reducing costs for tenants. With support from organizations like Helgeland Knowledge Park and Rana Development, the park has become a hub for resource optimization. Spanning 300 hectares and 350,000 square meters of built space, its layout encourages close collaboration among businesses, further enhancing efficiency and innovation [11].

4. Amata Industrial Park, Vietnam

Located in Bien Hoa, Vietnam, Amata Industrial Park serves as a pilot for the Eco-Industrial Park model. Spanning 1.97 square miles (5.1 km²), this initiative was chosen by Vietnam's Ministry of Planning and Investment alongside UNIDO to lead a significant transformation. Between 2020 and 2024, compliance with international standards at the park increased from 41% to 86% [13]. Below, we explore its resource management strategies, industrial collaboration efforts, and renewable energy advancements.

Resource Efficiency and Waste Minimization

Amata Industrial Park operates on the principles of "Reduce, Reuse, and Recycle" to manage resources and cut waste. Its wastewater treatment plants process 35,700 cubic meters (9.4 million gallons) daily, amounting to an annual total of 13 million cubic meters (3.4 billion gallons) [14]. A Reverse Osmosis filtration system reclaims water for industrial use, green space irrigation, and cooling power plants, reducing fresh water demand by as much as 40% [14]. As Mr. Chuchat Saitin, Managing Director of AMATA Water Company Limited, puts it:

Our water management principles are based on a circular economy system with an efficient use of natural resources, known as the 3 R's: Reduce, Reuse and Recycle [14].

The park's waste management system achieves outstanding results. At Amata City Chonburi, for instance, only 0.06% of waste ends up in landfills [14]. Non-recyclable solid waste is converted into refuse-derived fuel for cement kilns, while a digital platform, the "Koom Kah Smart Manifest", simplifies waste collection and promotes recycling. In a notable project from October 2018, Amata collaborated with Dow Thailand Group and Siam Cement Group (SCG) to create recycled plastic roads. This effort repurposed 16.89 tons of plastic waste into 1,990 meters (6,529 feet) of asphalt road [14].

Industrial Symbiosis and Cross-Industry Collaboration

Through the Global Eco-Industrial Parks Program (GEIPP), funded by the Swiss State Secretariat for Economic Affairs (SECO), Amata has helped 18 tenant businesses - including Fleming, Shiseido, Saitex, Brother, and Toshiba - adopt cleaner production techniques and energy-efficient practices [15]. The park's licensing process enforces a closed-loop supply chain, ensuring that one company’s waste becomes raw material for another [15].

Renewable Energy Integration

Amata is also advancing renewable energy use by incorporating floating solar installations, which add 2,152 kWp of capacity to power its water treatment facilities [14]. These solar projects align with the park’s Green Energy goals, attracting international investment while addressing climate challenges. Additionally, its advanced wastewater treatment plants, equipped with online monitoring systems, ensure that no untreated water enters public canals or natural watersheds [14][16].

5. Cleantech Park, Singapore

Spanning 123.5 acres in Singapore's Jurong Innovation District, Cleantech Park stands as the country's first eco-business park and a hub for sustainable manufacturing initiatives [18]. Developed by JTC Corporation in collaboration with the Singapore Economic Development Board, the park gained recognition in November 2012 as the first in Singapore to receive the BCA Platinum Green Mark for Districts Award [19]. At its core is the $90 million CleanTech One complex, home to over 22 organizations, including DHI Water and Environment from Denmark, Toray Industries from Japan, and Sinomem Technology from China [17]. The park’s design emphasizes resource efficiency, collaboration, and renewable energy solutions, creating a forward-thinking environment for innovation.

Resource Efficiency and Waste Reduction

Cleantech Park’s infrastructure is designed to minimize resource use. At CleanTech One, a low voltage direct current (LVDC) grid - tested by NTU's Energy Research Institute and Royal Philips Electronics in early 2013 - manages LED lighting, cutting energy consumption by up to 45% [18]. The "Sky Trellis", a landscaped trellis garden, helps lower ambient temperatures and reduces the need for air conditioning. Meanwhile, a "blue network" of streams and bioswales collects approximately 150,000 liters of stormwater annually, which is reused for sanitary flushing, reducing potable water consumption by 25% [19]. These measures not only conserve resources but also establish a strong foundation for industrial collaboration within the park.

Collaboration Across Industries and Academia

Situated near Nanyang Technological University, Cleantech Park fosters a dynamic ecosystem where academic research and industrial innovation intersect. It hosts institutions like the Solar Energy Research Institute of Singapore (SERIS) and the Advanced Remanufacturing and Technology Centre (ARTC), encouraging knowledge exchange between researchers and manufacturers [19]. Associate Professor Tan Soon Keat, Deputy Executive Director of NEWRI, highlights this collaborative spirit:

"CleanTech One is about creating opportunity. We do not know whom we may run into in the elevator. It could be someone with the solution to a problem that we have had for some time." [18]

Additionally, CleanTech Two offers 240,000 square feet of specialized workshop space to support research, prototyping, and the transition of concepts into commercially viable manufacturing [17].

Embracing Renewable Energy Solutions

Cleantech Park also integrates renewable energy to reduce utility costs and promote sustainability. Solar panels installed across CleanTech One, Two, and Three generate clean energy for the park, while a district-level energy monitoring system ensures real-time optimization of consumption [19]. In early 2013, Real Time Engineering tested a 1-megawatt hydrogen fuel cell system at CleanTech One, providing clean energy to over 20% of the common areas [18]. Together with energy-efficient infrastructure, these renewable energy initiatives contribute to an estimated 40% reduction in annual utility costs. By 2012, CleanTech One achieved 70% occupancy, attracting global clean energy leaders like Yingli Solar [19].

Key Metrics Comparison

The performance metrics of these parks provide a closer look at their tangible impacts. Kalundborg Symbiosis stands out with its measurable achievements in resource efficiency and cost reduction. This industrial symbiosis network facilitates around 50 different exchange processes involving 30 types of materials - such as steam, water, ash, gypsum, and biomass - among 12 public and private entities. These exchanges lead to a reduction of 270,000 tons of CO₂ emissions annually and yield cost savings estimated between $72 million and $87 million each year[3].

Mette Skovbjerg, Head of the Symbiosis Center, highlights the practical motivations behind these collaborations:

The driver for this type of collaboration is actually to reduce production costs, not CO₂ emissions. The real issue is to achieve primary goals companies have; to secure supplies and access to resources.[3]

This pragmatic approach allows companies to reimagine waste as a resource, turning potential liabilities into valuable assets.

While Kalundborg sets a high benchmark, other eco-industrial parks are adopting frameworks developed by organizations like UNIDO and the World Bank. However, their data is often less comprehensive. Globally, the growth of eco-industrial parks is accelerating, with more than 55.9% of the world’s 438 parks established since 2001. This trend reflects the increasing adoption of circular economy models worldwide[21].

Parks with a long history, like Kalundborg, demonstrate the most quantifiable benefits, offering a blueprint for success. In contrast, newer parks show promise but often lack detailed metrics to fully capture their impact. The ability to foster deep industrial symbiosis remains crucial for achieving both economic and environmental progress.

Conclusion

These five parks showcase how prioritizing cost savings, resource efficiency, and risk management can lead to thriving circular economy models. Peter Laybourn, CEO of International Synergies, encapsulates this approach perfectly:

We use the language of business. We don't talk about emissions, we talk about risks and profit. But it just so happens... we end up getting the environmental benefits as well. [3]

The global rise in adoption, from 245 parks in 2001 to 438 in 2020[22], reflects a growing industry commitment to these principles. Achieving success in this space hinges on having dedicated park operators who can effectively manage the intricate flows of materials, nurture trust among companies, and establish the legal frameworks necessary for resource sharing[22]. Without this essential coordination, even the best-intentioned symbiosis efforts face challenges in scaling. This upward trend highlights the importance of actionable and well-structured strategies.

To put these strategies into practice, begin by identifying existing waste streams that currently incur disposal costs but could serve as valuable inputs for other processes. Tools like the UNIDO EIP Toolbox can help pinpoint symbiosis opportunities and funding sources[20]. Focus on exchanges involving non-sensitive materials - such as steam, wastewater, ash, and gypsum - where companies can realize immediate benefits without compromising proprietary information[12].

Advancements in digital platforms now allow real-time tracking of energy, water, and material flows[22], while incentives like tax credits and simplified permitting processes further lower barriers to implementation[1].

These examples prove that industrial symbiosis is not only feasible but also delivers tangible financial and operational returns. They reinforce the article's central message: profitability and sustainability go hand in hand. The framework is proven - the challenge lies in how quickly these strategies can be adapted and applied at a local level.

FAQs

How do eco-industrial parks improve resource efficiency?

Eco-industrial parks (EIPs) improve how resources are used by applying industrial symbiosis - a system where one company’s waste or byproducts become valuable inputs for another. This setup minimizes the demand for new resources by creating a circular exchange of materials, energy, and water within the park. For example, surplus heat, steam, or electricity produced by one facility can be redirected to nearby businesses, reducing both waste and expenses.

A standout example is the Kalundborg Symbiosis in Denmark. Here, wastewater from biotech companies is heated and integrated into a district heating system. This process raises water temperatures from 55°F to 80°F, eliminating the need for fossil-fuel-based heating in the community. Advanced technologies like energy-sharing platforms, real-time energy mapping, and shared infrastructure further streamline these exchanges, creating an efficient closed-loop system. These approaches not only cut environmental impact but also help manufacturers achieve sustainable and profitable growth, both in the United States and globally.

What are the key benefits of industrial symbiosis in eco-industrial parks?

Industrial symbiosis transforms waste from one company into a resource for another, delivering benefits across economic, environmental, and social dimensions. By sharing resources such as surplus heat, steam, water, or by-products, businesses can significantly cut operating expenses, boost efficiency, and lower energy consumption. A prime example is Kalundborg, Denmark, where waste heat from a power plant is used for district heating, reducing both fuel costs and energy use.

From an environmental perspective, this approach reduces waste and curbs greenhouse gas emissions by turning potential pollutants into useful inputs. This not only aligns with sustainability objectives but also generates measurable cost savings and efficiency improvements.

On a broader community level, industrial symbiosis encourages collaboration among businesses, service providers, and local governments, fostering regional growth and strengthening social ties. Organizations like Council Fire assist companies in adopting these strategies, blending financial success with environmental responsibility and community engagement.

How do eco-industrial parks help lower carbon emissions?

Eco-industrial parks are reshaping how industries manage resources and energy, offering a practical way to cut carbon emissions. These parks operate on the principle of turning waste into valuable resources. For instance, businesses within these parks can share by-products like waste heat, steam, or materials such as gypsum. This approach allows companies to replace traditional fossil fuels with recovered energy or renewable sources, leading to significant reductions in CO₂ emissions. A prime example is Denmark’s Kalundborg Symbiosis, where businesses collaborate to redirect resources like steam and ash, achieving impressive carbon savings.

Another advantage of eco-industrial parks is their ability to reduce emissions tied to transportation and raw material extraction. By clustering industries with complementary needs, they lower the reliance on long-distance shipping and cut fuel consumption. This model is particularly impactful in countries like China, where industrial parks are a significant source of energy use and greenhouse gas emissions. By adopting clean production methods and embracing circular economy principles, these parks are paving the way for more sustainable industrial systems. Council Fire plays a key role in helping organizations implement these strategies, ensuring they balance environmental progress with economic viability.

Related Blog Posts

FAQ

What does it really mean to “redefine profit”?

What makes Council Fire different?

Who does Council Fire you work with?

What does working with Council Fire actually look like?

How does Council Fire help organizations turn big goals into action?

How does Council Fire define and measure success?