Jan 2, 2026

Jan 2, 2026

Automated Waste Systems: Key Technologies

Sustainability Strategy

Sustainability Strategy

In This Article

IoT, AI, robotics, pneumatic networks and solar compactors are reshaping urban waste collection—cutting emissions, costs, and boosting recycling efficiency.

Automated Waste Systems: Key Technologies

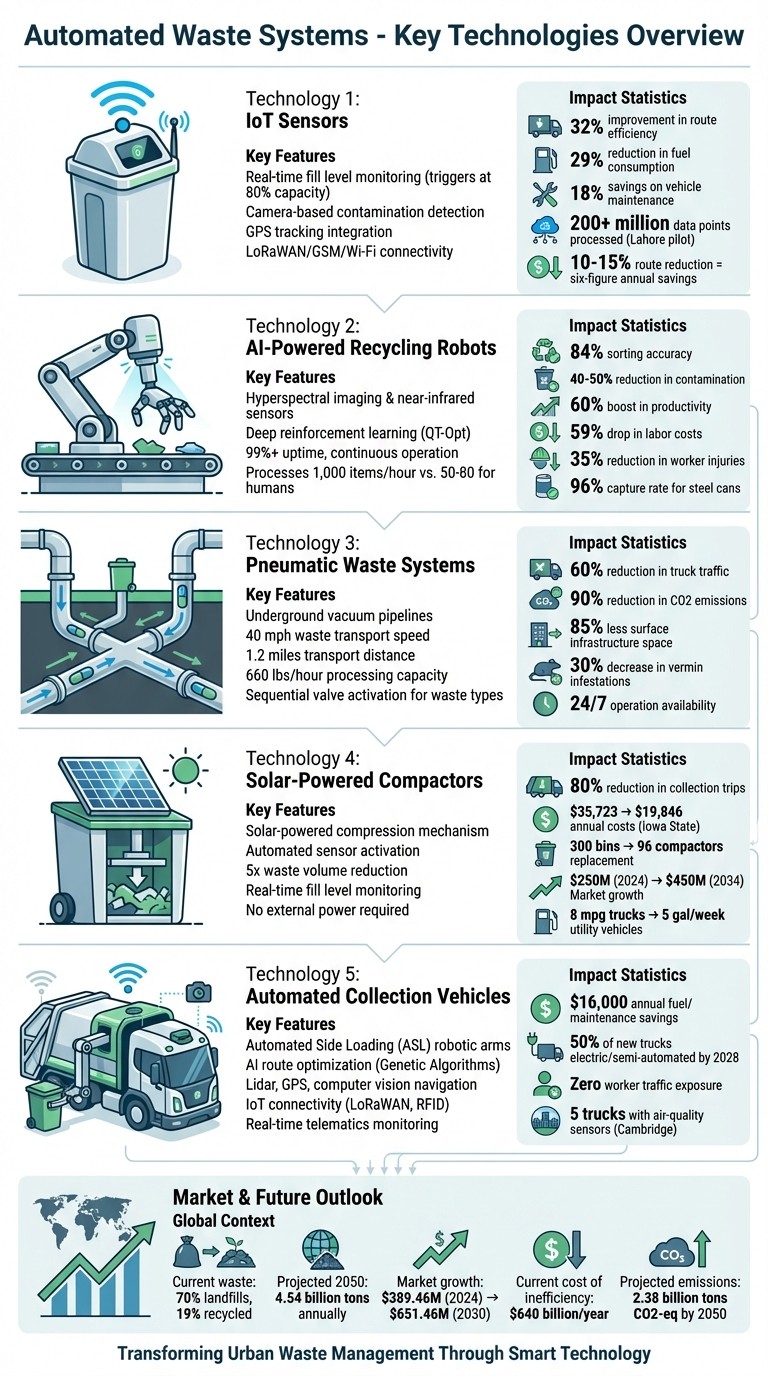

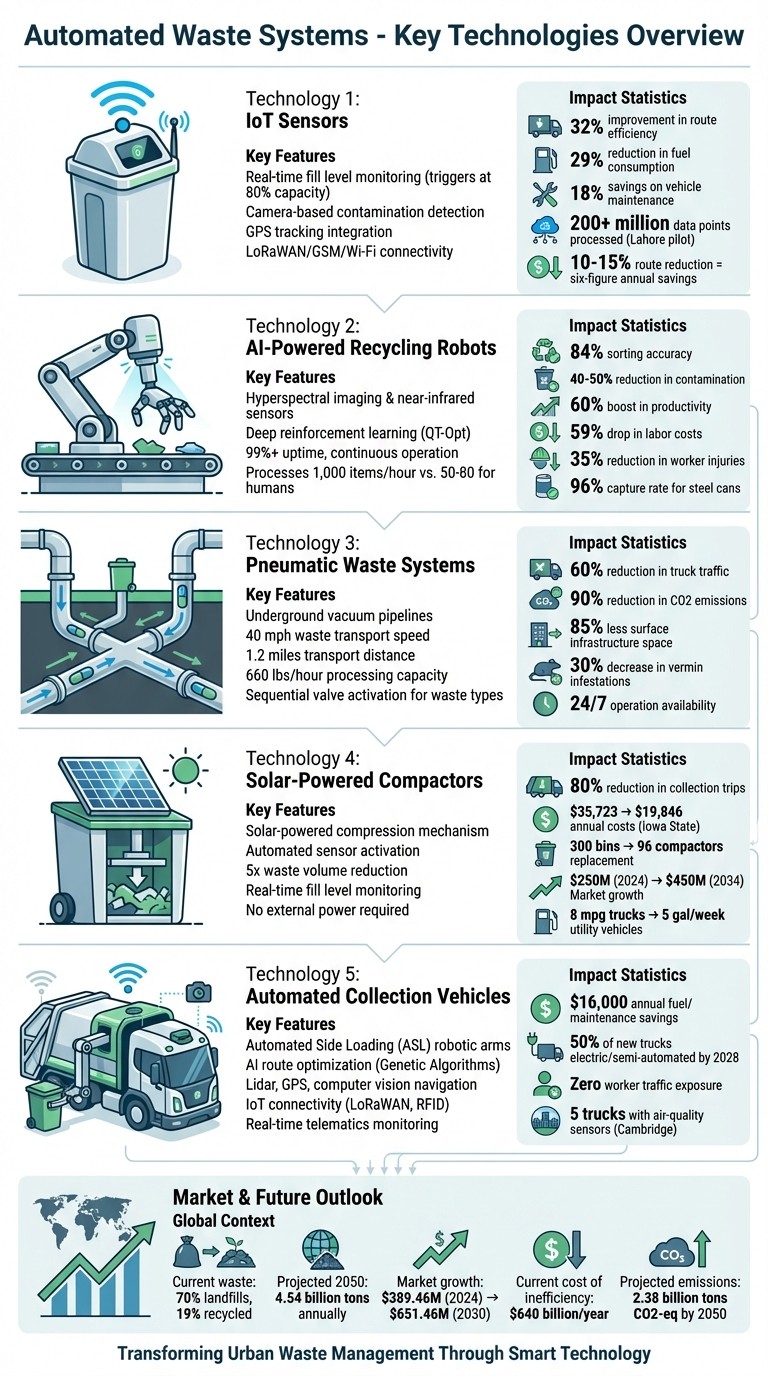

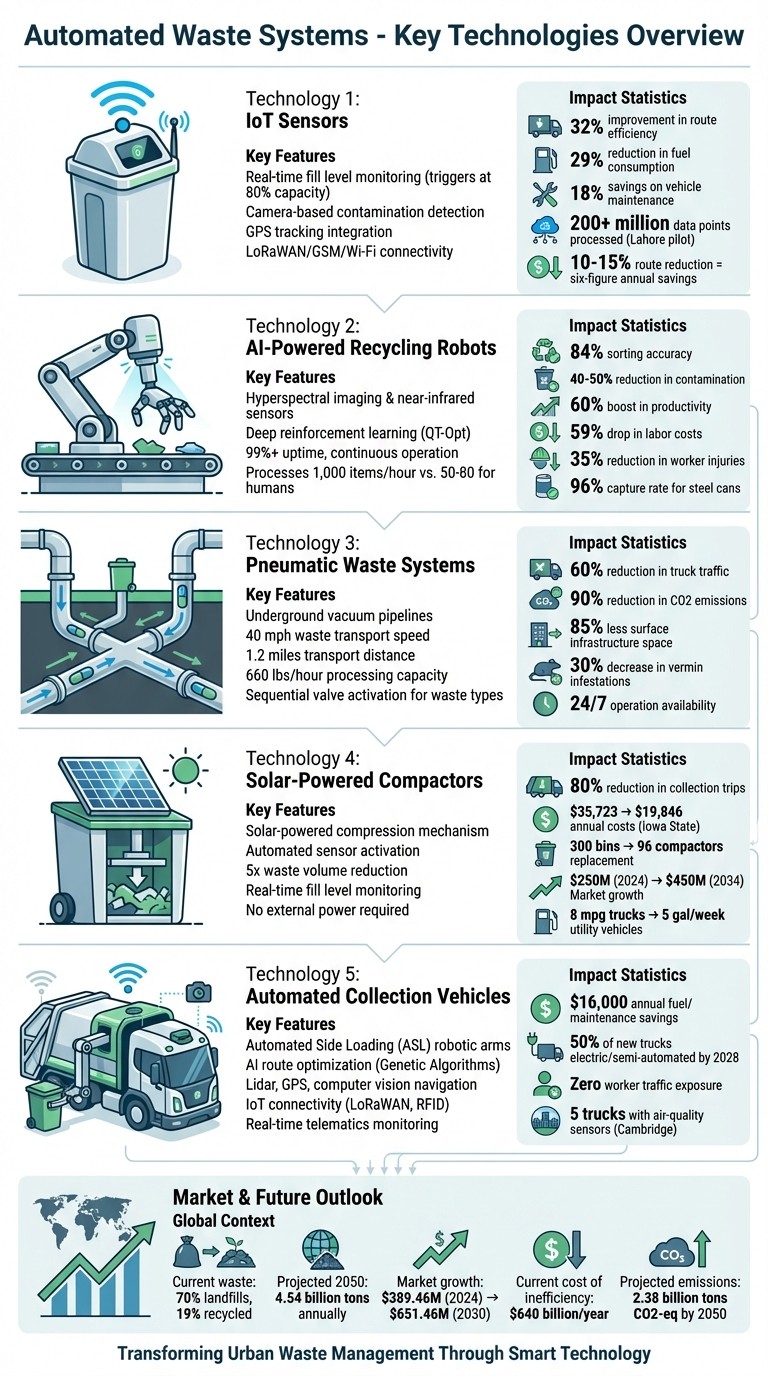

Automated waste systems are transforming how cities manage the growing challenge of waste production, which is expected to reach 4.54 billion tons annually by 2050. These systems integrate IoT sensors, AI, robotics, and other technologies to improve efficiency, reduce emissions, and lower operational costs. Key advancements include:

IoT Sensors: Monitor bin fill levels in real-time, optimizing collection routes and reducing fuel use by up to 29%.

AI-Powered Recycling Robots: Sort recyclables with up to 84% accuracy, processing materials faster and cutting contamination by 40%.

Pneumatic Waste Systems: Use underground pipelines to transport waste, reducing truck traffic by 60% and emissions by 90%.

Solar-Powered Trash Compactors: Compress waste using solar energy, reducing collection trips by 80%.

Automated Waste Vehicles: Equipped with robotic arms and AI for safer, more efficient collection.

These technologies are reshaping urban waste management by optimizing processes, improving safety, and supporting broader sustainability goals. The market for automated waste solutions is projected to grow from $389.46 million in 2024 to $651.46 million by 2030, reflecting increasing adoption worldwide.

5 Key Automated Waste Technologies: Features, Benefits & Impact Statistics

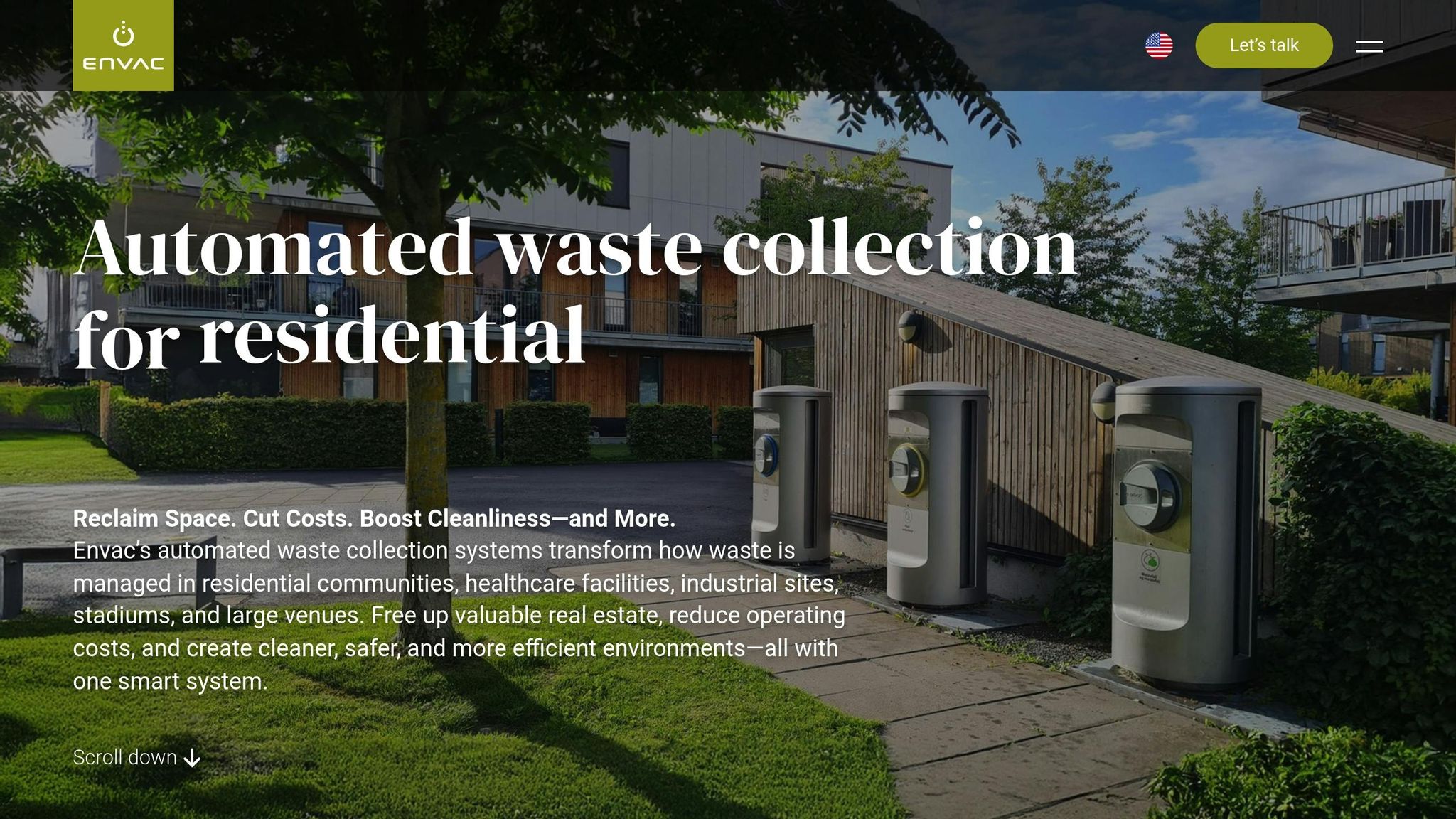

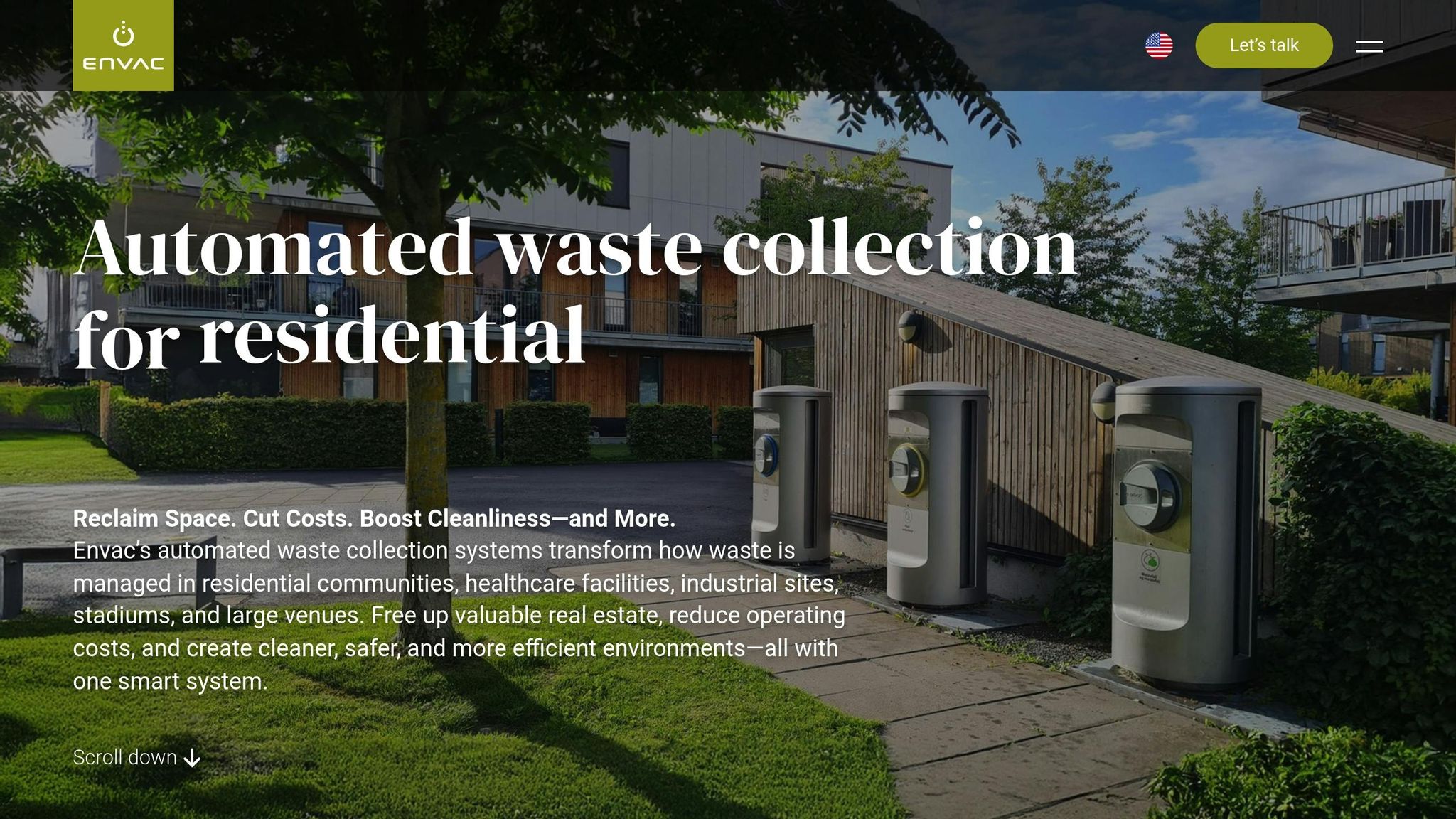

The Envac System - Automated waste collection for smart cities

IoT Sensors for Real-Time Waste Monitoring

IoT sensors are transforming waste management by offering real-time insights into bin fill levels. These sensors, often ultrasonic or infrared, are installed inside waste containers to measure the distance to the waste surface, allowing for precise calculation of how full the bin is. When a bin reaches a set capacity - commonly 80% - the system notifies dispatchers to schedule a pickup [6][7]. This approach eliminates the inefficiencies of traditional fixed-route collection, where trucks either visit bins that are only partially full or miss bins that are already overflowing.

In addition to monitoring fill levels, advanced camera-based sensors leverage computer vision and AI to detect issues like recycling contamination or illegal dumping, enabling timely interventions [6][1]. GPS modules integrated into bins and collection vehicles provide exact location data, allowing managers to map out containers and monitor truck routes in real time [6][4]. Data collected by these sensors is transmitted through technologies like LoRaWAN, GSM, or Wi-Fi to cloud platforms, where route optimization engines dynamically adjust collection schedules [6][8].

The benefits are clear. A large-scale pilot in Lahore, Pakistan, conducted in July 2024, utilized ultrasonic sensors and LoRaWAN to process over 200 million data points. The results were impressive: a 32% improvement in route efficiency, a 29% reduction in fuel consumption and emissions, and 18% savings on vehicle maintenance [8]. For U.S. cities, cutting route miles by just 10% to 15% can result in annual savings in the six-figure range [6].

Advantages of IoT Sensors

The advantages of IoT sensors go well beyond fuel savings. Dynamic routing based on real-time data eliminates unnecessary trips to empty bins, reducing mileage and wear on vehicles and roads [6][8]. For example, in 2023, Columbus, Ohio, managed to cut bulk-item collection stops by over 15%, saving four hours of staff time weekly and delaying the need for additional truck purchases [6].

These systems also enhance resource management by predicting staffing needs and reallocating trucks during peak times or seasonal spikes [6]. Camera-based sensors provide continuous monitoring of recycling compliance, replacing occasional manual inspections with automated oversight [6]. Harold Mitchell, a consultant at Raftelis Financial Consultants, highlights the broader implications:

"When waste systems talk - through sensors, telematics, dashboards, and utility data connections - smart communities can listen, learn, and iterate to make improvements quickly" [6].

Some cities are even linking waste management platforms with water and electric utility data to identify vacant properties and avoid unnecessary stops [6]. This integration is reshaping urban operations, turning waste collection into a key component of a more interconnected smart-city ecosystem. The move from static paper maps to live GIS dashboards that update in real time on driver tablets marks a significant shift in how municipalities manage their services [6].

Challenges of IoT Sensors

Despite the clear benefits, deploying IoT systems city-wide is not without challenges. High initial costs for sensors, network infrastructure, and software can be a major hurdle, especially for smaller municipalities [6][8]. Power and battery life are additional concerns; sensors require consistent energy sources, and frequent battery replacements can drive up operational costs [8][4]. Wireless technologies like Wi-Fi and Zigbee also face limitations in range and struggle with obstacles in dense urban settings [4].

Data security is another critical issue. IoT systems are susceptible to jamming, spoofing, and data breaches, necessitating robust encryption methods such as AES for LoRaWAN and TLS for cellular and cloud communications [8]. Many cities also face difficulties integrating IoT data with existing platforms like 311 services, GIS maps, or utility databases. Achieving seamless integration requires careful coordination across operations, finance, and IT departments [6][8]. As Mitchell puts it:

"Implementing IoT in waste management is not a silver bullet. It requires investment, detailed planning (operations, finance, and IT capabilities), integration, and training" [6].

Durability is another concern. Sensors must endure harsh conditions, such as extreme weather, physical damage, and exposure to corrosive waste. To address this, many cities have adopted solar-powered ultrasonic sensors, which offer extended operational life [6][8][4]. The adoption of LoRaWAN as the preferred communication protocol has also helped overcome connectivity challenges. LoRaWAN provides long-range coverage - between 2 and 5 kilometers - while consuming minimal power, making it particularly suitable for urban waste systems [8][4]. By using a hierarchical setup where sensors communicate with gateways via LoRaWAN and only aggregated data is sent through cellular networks, cities can keep transmission costs low without compromising reliability [8].

While these challenges highlight the complexities of IoT adoption, they also pave the way for further advancements, which will be explored in the next section on AI-powered recycling robots.

AI-Powered Recycling Robots

AI-powered recycling robots are revolutionizing material recovery facilities (MRFs) by employing advanced sensors and machine learning to sort recyclables with remarkable precision. Equipped with high-resolution cameras, hyperspectral imaging, and near-infrared sensors, these systems can identify materials based on their chemical makeup and immediately direct them into the correct recycling streams [11][9].

The efficiency of these robots far surpasses human capabilities. While a human worker typically sorts 50–80 items per hour, AI robots can process up to 1,000 items per hour, operating continuously with over 99% uptime [11]. This translates to a 50% increase in facility operating hours compared to human labor, all while addressing challenges like staffing shortages and high turnover rates [11].

Advancements in deep reinforcement learning frameworks, such as QT-Opt, further enhance these systems. For example, Google Research deployed 23 reinforcement learning-enabled robots between 2021 and 2022, conducting 540,000 trials in controlled environments and 32,500 trials in real-world conditions. These efforts resulted in an 84% sorting accuracy and a 40–50% reduction in bin contamination [10]. As researchers noted:

"The final system could accurately sort about 84% of the objects on average, with performance increasing steadily as more data was added" [10].

Case Studies of AI Robots

Real-world applications highlight the transformative impact of AI robots in recycling. Midwest Recycling Service, for instance, implemented Waste Robotics’ automated construction and demolition (C&D) sorting line. With three robotic arms in operation, the facility now achieves over 90% material capture. As President Justin Rice shared:

"Now, with three sorting arms, we achieve over 90% capture" [9].

In France, Altriom 2.0 integrated a Waste Robotics hyperspectral system to tackle the challenge of sorting visually similar but chemically distinct materials. This AI-driven system successfully identified all incoming materials, delivering high-purity sorted streams. Operations Manager Hugo Simme remarked:

"Waste Robotics helped us overcome a challenge with complex materials. Thanks to their hyperspectral system and AI implemented in the material detection system, we succeeded in identifying all the materials arriving on our line, achieving high-quality sorting" [9].

Closer to home, Alameda County Industries near San Francisco saw labor costs drop by 59% after adopting AI robots. These machines operate consistently around the clock, and their leasing costs are roughly equivalent to the annual salaries of one to two workers, making them a cost-effective solution even for mid-sized facilities [11].

Impact on Recycling Efficiency

The introduction of AI-powered robots has significantly improved recycling efficiency. Facilities report a 60% boost in overall productivity and a 35% reduction in worker injuries, as robots handle hazardous materials that would otherwise pose risks to human sorters [11]. Additionally, contamination in recycling streams has decreased by nearly 40%, ensuring more materials meet the purity standards required by manufacturers [11].

While current MRFs capture about 87% of accepted recyclables, AI-driven systems are pushing these rates even higher. Automated sorting now achieves 96% capture rates for steel cans and 93% for HDPE bottles and jars [12]. This progress helps reduce the estimated 30% of potentially valuable recyclables lost to landfills due to human error or outdated equipment [11]. In North America alone, 340 waste facilities have already been upgraded with AI technology, and adoption is expected to grow at an annual rate of 22% through 2030 [11].

Advanced systems like Greyparrot can now classify waste into 111 distinct categories, while AMP ONE identifies over 50 categories [11]. Some systems even recognize specific brand logos on packaging, opening the door for corporate accountability in managing packaging waste [11]. By producing higher-purity recycled materials, AI robots are creating stronger markets for recycled goods and reducing dependence on virgin resources, making them a cornerstone of modern waste management practices.

Pneumatic Waste Systems

Expanding on advancements like sensor-driven and robotic waste solutions, pneumatic waste systems present a futuristic underground alternative. Often referred to as Automated Vacuum Collection Systems (AVCS), these setups rely on underground pipelines and negative air pressure to move waste from street-level inlets directly to a central processing facility. Here’s how it works: residents drop their trash into designated inlets equipped with temporary valves. When triggered, vacuum pumps generate negative pressure, propelling waste through the network of pipes at speeds reaching 40 miles per hour, with the ability to transport waste up to 1.2 miles away [13][15].

The system comprises an underground pipe network, vacuum stations, and a central facility where automation handles sorting and compacting. Real-time communication tools monitor fill levels to ensure efficiency [13]. To prevent waste streams from mixing, the system sequentially activates valves for different waste types - such as recyclables, organic waste, and general trash [13][15]. At the central terminal, waste is sorted automatically using cyclonic separation, compacted, and sealed into containers for transport to recycling plants or landfills [13][15]. Impressively, each inlet can process up to 660 pounds of waste per hour, operating continuously around the clock [15]. This streamlined approach not only accelerates waste collection but also sets the stage for transformative urban infrastructure improvements.

Countries like South Korea, Singapore, and Sweden have successfully implemented these systems, showcasing how sensor-equipped inlets and pneumatic pipes can revolutionize urban waste management [13][16].

Advantages of Pneumatic Systems

Pneumatic systems offer more than just operational speed - they bring substantial environmental and urban planning benefits. By cutting heavy vehicle traffic by 60% and reducing CO2 emissions from waste collection by 90%, these systems make a noticeable environmental impact [13][15]. As Rohan Bansal and Joydeep Bhattacharyya from Transforma Insights explain:

"The elimination of collection trucks is one of the major benefits of deploying vacuum tube systems as they can eliminate emissions caused by pick-up trucks by up to 90%." [13]

These systems also save valuable urban space, requiring just 15% of the surface area used by traditional waste collection infrastructure. This opens up opportunities for parks, housing, or commercial spaces [13]. Additionally, the sealed underground network minimizes vermin infestations by 30% and eliminates common issues like overflowing bins, odors, and pests. Unlike rigid truck-based schedules, pneumatic systems allow residents to dispose of waste at their convenience, improving hygiene and making waste management more user-friendly.

Implementation Considerations

Despite their advantages, the high upfront costs of installing underground pipe networks and central vacuum stations remain a key challenge [13]. The complexity of installation varies greatly: while new developments can seamlessly integrate pneumatic systems during the planning phase, retrofitting older neighborhoods requires significant excavation and coordination with existing utilities [13][14].

For established areas, successful adoption hinges on community cooperation and precise engineering. These systems demand specialized maintenance to ensure long-term reliability [13]. While the initial costs are steep, developers can offset expenses by utilizing the 85% of infrastructure space saved compared to conventional waste setups. This reclaimed space can be repurposed for additional housing, amenities, or commercial projects, adding long-term value [13]. Over time, operational savings from reduced labor, lower fuel consumption, and fewer maintenance needs for traditional waste systems help to offset the initial investment [14][15].

For municipalities, integrating pneumatic waste systems early in the planning stages of new high-density developments is a practical approach to minimize costs and streamline implementation [13].

Solar-Powered Trash Compactors

Solar-powered compactors provide an efficient above-ground alternative to underground pneumatic systems. These units harness solar energy through panels mounted on top to power an internal mechanism that compresses waste as it builds up. Equipped with sensors, they automatically activate the compaction process once the trash reaches a certain level [17]. This technology can reduce the volume of waste by as much as five times compared to traditional bins [25, 29].

At Iowa State University, this system significantly cut waste management expenses, dropping annual litter removal costs from $35,723 in 2008 to $19,846 by 2015. The university replaced 300 traditional concrete bins with 96 solar-powered compactors, which allowed them to switch from large trucks averaging 8 miles per gallon to smaller utility vehicles consuming just 5 gallons of gas weekly [17]. Merry Rankin, Director of Sustainability Programs at the university, highlighted the broader impact:

"This supports social sustainability by making the most efficient use of our teams' skills and expertise" [17].

Environmental Benefits

Solar-powered compactors contribute to a cleaner environment by reducing the frequency of waste collection by up to 80%, which in turn lowers emissions from collection vehicles [25, 28]. Traditional garbage trucks, which average only 8 miles per gallon, require fewer trips, directly reducing greenhouse gas emissions and improving air quality [17]. Additionally, the enclosed design of these compactors prevents litter from being scattered by the wind and keeps animals from accessing the trash [25, 26].

Running solely on solar energy, these compactors eliminate the need for external power sources, making them particularly useful in remote locations like parks, beaches, and areas where connecting to the electrical grid is either impractical or too expensive [25, 26]. The global market for solar-powered trash compactors was valued at approximately $250 million in 2024 and is expected to grow to $450 million by 2034, signaling increasing interest in sustainable urban infrastructure [18].

Much like sensor-driven and AI-enabled systems, solar-powered compactors simplify waste management while promoting eco-friendly urban development.

Operational Efficiency

Solar-powered compactors also enhance operational efficiency by incorporating advanced sensor technology. These sensors send real-time data on fill levels to a central management system, allowing waste collection teams to dispatch trucks only when bins are nearly full, rather than following fixed schedules [25, 27]. This approach optimizes routes, reduces fuel consumption, and lowers vehicle maintenance costs [26, 31].

In October 2023, Bigbelly Solar partnered with a leading urban waste management company to roll out smart solar-powered compactors across cities in North America. Using real-time data analytics, this initiative aims to streamline collection routes and cut operational expenses [18]. That same year, Ecube Labs introduced the CleanCube 3000, a model equipped with upgraded sensors and a mobile app for remote monitoring and performance tracking [18].

Although the initial investment for these compactors can be significant, cities can recoup costs over time through savings on labor, fuel, and vehicle upkeep [17]. Additionally, these units can be integrated into broader smart infrastructure plans, serving as multifunctional hubs that monitor air quality, noise levels, or even foot traffic patterns [19].

Automated Waste Collection Vehicles

With the integration of sensors and AI-driven technologies, automated waste collection vehicles are transforming the way trash is managed. These trucks combine robotic arms, AI-powered navigation, and real-time data systems to make operations more efficient and safer for workers. A standout feature is the Automated Side Loading (ASL) arm, which allows drivers to operate a mechanical arm from inside the cab using a joystick. This eliminates the need for workers to manually handle bins or navigate busy traffic on foot, significantly improving safety [3]. Additionally, these vehicles leverage AI-driven route optimization, using algorithms such as Genetic Algorithms and Reinforcement Learning to analyze data from IoT-enabled smart bins. This ensures the most fuel- and time-efficient collection routes [1].

For instance, Miami-Dade County in Florida introduced a fully electric garbage truck equipped with ASL technology [3]. Similarly, Volvo has piloted an autonomous refuse truck in Sweden that uses lidar for obstacle detection and preprogrammed routes, optimizing gear shifts and steering to reduce emissions [3].

Key Technologies

A host of advanced technologies drives the functionality of these automated vehicles. Lidar, GPS, and computer vision are essential for autonomous navigation, enabling trucks to map routes, detect obstacles, and operate without direct human control [3][20]. Cameras installed on trucks can identify overflowing bins, potholes, and infrastructure issues in real time, feeding valuable data into management systems for better operational planning [3][20]. For example, in Cambridge, Massachusetts, five garbage trucks were equipped with air-quality sensors and infrared cameras to gather urban data during their daily routes [3].

IoT connectivity, using systems like LoRaWAN, GPRS, and RFID, ensures constant communication between vehicles, waste bins, and central monitoring stations. This technology monitors bin fill levels and tracks vehicle locations [4][5]. Telematics systems further enhance efficiency by providing fleet managers with detailed performance metrics, enabling them to adjust routes dynamically and respond to service requests more effectively. In another innovative step, the German company Angsa Robotics raised €2.5 million to develop an autonomous waste collection robot with an 8-hour battery life, designed specifically for parks and large events [20]. These technologies exemplify the powerful intersection of robotics and IoT in modern urban services.

Pros and Cons

While automated waste collection vehicles bring numerous advantages, they also come with certain challenges. For example, in 2021, Mount Airy, North Carolina, purchased a semi-automated garbage truck for $760,000, aiming to reduce costs by phasing out some collector roles through attrition [3]. All-electric trucks with ASL technology are also projected to save approximately $16,000 annually in fuel and maintenance costs [3].

Feature | Advantages | Disadvantages |

|---|---|---|

Labor | Keeps workers safely in the cab, reducing manual labor [3] | May lead to job displacement or role shifts [3] |

Efficiency | Optimized routes cut fuel use, emissions, and wear-and-tear [1][3] | High initial costs compared to traditional trucks [3] |

Safety | Limits worker exposure to traffic, sharp objects, and heavy lifting [3] | Advanced sensors and robotics require specialized maintenance [3] |

Sustainability | Supports zero-emission goals when combined with electric drivetrains [3] | Full autonomy depends on high-quality mapping and infrastructure [3] |

The National Academies of Sciences, Engineering, and Medicine highlights the safety benefits of automation:

"The ASL arm avoids the need for workers to be exposed to traffic and other hazards associated with the traditional hands-on method of emptying bins" [3].

Although the upfront costs of these vehicles can be steep, cities often recover their investment through reduced labor expenses, lower fuel consumption, and a decrease in workplace injuries over time.

The Future of Automated Waste Systems

Automated waste technologies are poised to reshape how cities manage waste. With 70% of waste currently ending up in landfills and only 19% being recycled, the global cost of inefficient waste management has reached an estimated $640 billion annually. By 2050, waste generation is expected to hit an overwhelming 4.54 billion tons [1]. However, advancements in AI, robotics, IoT sensors, and autonomous vehicles present an opportunity to reverse these trends, reduce emissions, and cut operational expenses.

Future waste systems will harness cutting-edge AI to analyze complex waste patterns and predict collection needs with precision [1]. Hyperspectral cameras and computer vision, integrated with robotics, will make it possible to identify and sort materials more accurately. This is especially crucial for handling challenging materials like film plastics and multilayered packaging, which still require manual sorting [1][21]. Additionally, LoRaWAN has emerged as the preferred communication protocol for urban smart bin networks due to its ability to cover long distances while consuming minimal power [4]. These innovations are paving the way for fully autonomous waste collection systems.

Autonomous waste collection fleets are already making headway. Leading waste management companies have announced plans to ensure that 50% of their new truck purchases will be electric or semi-automated by 2028 [3]. These vehicles will rely on Lidar technology and optimized preprogrammed routes, which will significantly reduce emissions and fuel costs. Meanwhile, cities are experimenting with decentralized solutions, such as Autonomous Mobile Robots (AMRs) for localized waste collection and modular smart composters for residential organic waste [2].

But the future of waste management isn’t just about collection - it’s about redefining waste as a resource. Advanced systems will go beyond sorting and recycling to convert waste into renewable energy sources. Organic waste, for instance, will increasingly be transformed into sustainable aviation fuel (SAF), biogas, and biohydrogen [1]. This shift not only aligns with environmental goals but also generates economic value from materials that would otherwise contribute to the projected 2.38 billion tons of CO2-equivalent emissions annually by 2050 if left unmanaged [1].

Organizations like Council Fire (https://councilfire.org) are helping municipalities and companies adopt these technologies. By aligning financial, environmental, and social priorities, they aim to create waste management systems that benefit both urban and rural communities. Achieving this vision requires phased implementation, active public participation, and data-driven strategies. These efforts promise to build waste systems that support both people and the planet, advancing sustainability in meaningful ways.

FAQs

How do IoT sensors make waste collection more efficient?

IoT sensors are revolutionizing waste collection by turning standard bins into smart, connected devices. These sensors keep tabs on fill levels, temperature, and location in real time, transmitting this data through low-power wireless networks. With this technology, waste operators can pinpoint which bins are full and exactly where they are, allowing crews to focus solely on bins that need attention. This targeted approach not only reduces unnecessary stops but also saves fuel, cuts down on vehicle wear and tear, and lowers labor expenses.

Beyond real-time tracking, predictive analytics adds another layer of efficiency by forecasting when bins are likely to overflow. This enables dynamic routing, allowing operators to optimize collection routes and reduce total driving distances. Continuous monitoring also helps identify the best spots for bin placement and ensures timely maintenance, which lowers operational costs and boosts recycling efforts.

Setting up IoT sensor systems, however, demands thoughtful planning and collaboration. Council Fire partners with municipalities and private waste services to design and implement these networks, ensuring they meet sustainability objectives while staying within budget.

What are the environmental advantages of pneumatic waste collection systems?

Pneumatic waste collection systems bring a fresh approach to managing waste, replacing traditional garbage trucks with underground, vacuum-powered pipelines. This shift not only cuts down on vehicle traffic and noise but also significantly reduces carbon emissions. Compared to diesel-powered trucks, these systems consume less energy, making them a more efficient alternative.

By keeping streets cleaner, they help prevent litter and runoff, which protects stormwater systems from contamination. Their sealed design also limits the release of methane and other harmful gases during transport, improving air quality and lessening their overall environmental footprint. Additionally, these systems centralize waste management, streamlining efforts to integrate recycling and composting. The result? Higher material recovery rates and less reliance on landfills.

Council Fire collaborates with municipalities and developers to evaluate these benefits and implement pneumatic waste solutions that align with long-term goals like achieving carbon neutrality and creating resilient urban spaces.

How do AI-powered robots improve recycling efficiency and accuracy?

AI-driven recycling robots leverage computer vision and machine learning to accurately identify and sort materials such as plastic, paper, glass, metal, and cardboard with an impressive accuracy rate exceeding 95%. By automating what has traditionally been a manual process, these robots drastically cut down on human errors and reduce contamination in recycling streams.

Beyond improving sorting accuracy, these robots play a crucial role in optimizing waste management systems. They boost material recovery rates and reduce the amount of waste sent to landfills, streamlining the recycling process and making it more efficient.

Related Blog Posts

Latest Articles

©2025

FAQ

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Jan 2, 2026

Automated Waste Systems: Key Technologies

Sustainability Strategy

In This Article

IoT, AI, robotics, pneumatic networks and solar compactors are reshaping urban waste collection—cutting emissions, costs, and boosting recycling efficiency.

Automated Waste Systems: Key Technologies

Automated waste systems are transforming how cities manage the growing challenge of waste production, which is expected to reach 4.54 billion tons annually by 2050. These systems integrate IoT sensors, AI, robotics, and other technologies to improve efficiency, reduce emissions, and lower operational costs. Key advancements include:

IoT Sensors: Monitor bin fill levels in real-time, optimizing collection routes and reducing fuel use by up to 29%.

AI-Powered Recycling Robots: Sort recyclables with up to 84% accuracy, processing materials faster and cutting contamination by 40%.

Pneumatic Waste Systems: Use underground pipelines to transport waste, reducing truck traffic by 60% and emissions by 90%.

Solar-Powered Trash Compactors: Compress waste using solar energy, reducing collection trips by 80%.

Automated Waste Vehicles: Equipped with robotic arms and AI for safer, more efficient collection.

These technologies are reshaping urban waste management by optimizing processes, improving safety, and supporting broader sustainability goals. The market for automated waste solutions is projected to grow from $389.46 million in 2024 to $651.46 million by 2030, reflecting increasing adoption worldwide.

5 Key Automated Waste Technologies: Features, Benefits & Impact Statistics

The Envac System - Automated waste collection for smart cities

IoT Sensors for Real-Time Waste Monitoring

IoT sensors are transforming waste management by offering real-time insights into bin fill levels. These sensors, often ultrasonic or infrared, are installed inside waste containers to measure the distance to the waste surface, allowing for precise calculation of how full the bin is. When a bin reaches a set capacity - commonly 80% - the system notifies dispatchers to schedule a pickup [6][7]. This approach eliminates the inefficiencies of traditional fixed-route collection, where trucks either visit bins that are only partially full or miss bins that are already overflowing.

In addition to monitoring fill levels, advanced camera-based sensors leverage computer vision and AI to detect issues like recycling contamination or illegal dumping, enabling timely interventions [6][1]. GPS modules integrated into bins and collection vehicles provide exact location data, allowing managers to map out containers and monitor truck routes in real time [6][4]. Data collected by these sensors is transmitted through technologies like LoRaWAN, GSM, or Wi-Fi to cloud platforms, where route optimization engines dynamically adjust collection schedules [6][8].

The benefits are clear. A large-scale pilot in Lahore, Pakistan, conducted in July 2024, utilized ultrasonic sensors and LoRaWAN to process over 200 million data points. The results were impressive: a 32% improvement in route efficiency, a 29% reduction in fuel consumption and emissions, and 18% savings on vehicle maintenance [8]. For U.S. cities, cutting route miles by just 10% to 15% can result in annual savings in the six-figure range [6].

Advantages of IoT Sensors

The advantages of IoT sensors go well beyond fuel savings. Dynamic routing based on real-time data eliminates unnecessary trips to empty bins, reducing mileage and wear on vehicles and roads [6][8]. For example, in 2023, Columbus, Ohio, managed to cut bulk-item collection stops by over 15%, saving four hours of staff time weekly and delaying the need for additional truck purchases [6].

These systems also enhance resource management by predicting staffing needs and reallocating trucks during peak times or seasonal spikes [6]. Camera-based sensors provide continuous monitoring of recycling compliance, replacing occasional manual inspections with automated oversight [6]. Harold Mitchell, a consultant at Raftelis Financial Consultants, highlights the broader implications:

"When waste systems talk - through sensors, telematics, dashboards, and utility data connections - smart communities can listen, learn, and iterate to make improvements quickly" [6].

Some cities are even linking waste management platforms with water and electric utility data to identify vacant properties and avoid unnecessary stops [6]. This integration is reshaping urban operations, turning waste collection into a key component of a more interconnected smart-city ecosystem. The move from static paper maps to live GIS dashboards that update in real time on driver tablets marks a significant shift in how municipalities manage their services [6].

Challenges of IoT Sensors

Despite the clear benefits, deploying IoT systems city-wide is not without challenges. High initial costs for sensors, network infrastructure, and software can be a major hurdle, especially for smaller municipalities [6][8]. Power and battery life are additional concerns; sensors require consistent energy sources, and frequent battery replacements can drive up operational costs [8][4]. Wireless technologies like Wi-Fi and Zigbee also face limitations in range and struggle with obstacles in dense urban settings [4].

Data security is another critical issue. IoT systems are susceptible to jamming, spoofing, and data breaches, necessitating robust encryption methods such as AES for LoRaWAN and TLS for cellular and cloud communications [8]. Many cities also face difficulties integrating IoT data with existing platforms like 311 services, GIS maps, or utility databases. Achieving seamless integration requires careful coordination across operations, finance, and IT departments [6][8]. As Mitchell puts it:

"Implementing IoT in waste management is not a silver bullet. It requires investment, detailed planning (operations, finance, and IT capabilities), integration, and training" [6].

Durability is another concern. Sensors must endure harsh conditions, such as extreme weather, physical damage, and exposure to corrosive waste. To address this, many cities have adopted solar-powered ultrasonic sensors, which offer extended operational life [6][8][4]. The adoption of LoRaWAN as the preferred communication protocol has also helped overcome connectivity challenges. LoRaWAN provides long-range coverage - between 2 and 5 kilometers - while consuming minimal power, making it particularly suitable for urban waste systems [8][4]. By using a hierarchical setup where sensors communicate with gateways via LoRaWAN and only aggregated data is sent through cellular networks, cities can keep transmission costs low without compromising reliability [8].

While these challenges highlight the complexities of IoT adoption, they also pave the way for further advancements, which will be explored in the next section on AI-powered recycling robots.

AI-Powered Recycling Robots

AI-powered recycling robots are revolutionizing material recovery facilities (MRFs) by employing advanced sensors and machine learning to sort recyclables with remarkable precision. Equipped with high-resolution cameras, hyperspectral imaging, and near-infrared sensors, these systems can identify materials based on their chemical makeup and immediately direct them into the correct recycling streams [11][9].

The efficiency of these robots far surpasses human capabilities. While a human worker typically sorts 50–80 items per hour, AI robots can process up to 1,000 items per hour, operating continuously with over 99% uptime [11]. This translates to a 50% increase in facility operating hours compared to human labor, all while addressing challenges like staffing shortages and high turnover rates [11].

Advancements in deep reinforcement learning frameworks, such as QT-Opt, further enhance these systems. For example, Google Research deployed 23 reinforcement learning-enabled robots between 2021 and 2022, conducting 540,000 trials in controlled environments and 32,500 trials in real-world conditions. These efforts resulted in an 84% sorting accuracy and a 40–50% reduction in bin contamination [10]. As researchers noted:

"The final system could accurately sort about 84% of the objects on average, with performance increasing steadily as more data was added" [10].

Case Studies of AI Robots

Real-world applications highlight the transformative impact of AI robots in recycling. Midwest Recycling Service, for instance, implemented Waste Robotics’ automated construction and demolition (C&D) sorting line. With three robotic arms in operation, the facility now achieves over 90% material capture. As President Justin Rice shared:

"Now, with three sorting arms, we achieve over 90% capture" [9].

In France, Altriom 2.0 integrated a Waste Robotics hyperspectral system to tackle the challenge of sorting visually similar but chemically distinct materials. This AI-driven system successfully identified all incoming materials, delivering high-purity sorted streams. Operations Manager Hugo Simme remarked:

"Waste Robotics helped us overcome a challenge with complex materials. Thanks to their hyperspectral system and AI implemented in the material detection system, we succeeded in identifying all the materials arriving on our line, achieving high-quality sorting" [9].

Closer to home, Alameda County Industries near San Francisco saw labor costs drop by 59% after adopting AI robots. These machines operate consistently around the clock, and their leasing costs are roughly equivalent to the annual salaries of one to two workers, making them a cost-effective solution even for mid-sized facilities [11].

Impact on Recycling Efficiency

The introduction of AI-powered robots has significantly improved recycling efficiency. Facilities report a 60% boost in overall productivity and a 35% reduction in worker injuries, as robots handle hazardous materials that would otherwise pose risks to human sorters [11]. Additionally, contamination in recycling streams has decreased by nearly 40%, ensuring more materials meet the purity standards required by manufacturers [11].

While current MRFs capture about 87% of accepted recyclables, AI-driven systems are pushing these rates even higher. Automated sorting now achieves 96% capture rates for steel cans and 93% for HDPE bottles and jars [12]. This progress helps reduce the estimated 30% of potentially valuable recyclables lost to landfills due to human error or outdated equipment [11]. In North America alone, 340 waste facilities have already been upgraded with AI technology, and adoption is expected to grow at an annual rate of 22% through 2030 [11].

Advanced systems like Greyparrot can now classify waste into 111 distinct categories, while AMP ONE identifies over 50 categories [11]. Some systems even recognize specific brand logos on packaging, opening the door for corporate accountability in managing packaging waste [11]. By producing higher-purity recycled materials, AI robots are creating stronger markets for recycled goods and reducing dependence on virgin resources, making them a cornerstone of modern waste management practices.

Pneumatic Waste Systems

Expanding on advancements like sensor-driven and robotic waste solutions, pneumatic waste systems present a futuristic underground alternative. Often referred to as Automated Vacuum Collection Systems (AVCS), these setups rely on underground pipelines and negative air pressure to move waste from street-level inlets directly to a central processing facility. Here’s how it works: residents drop their trash into designated inlets equipped with temporary valves. When triggered, vacuum pumps generate negative pressure, propelling waste through the network of pipes at speeds reaching 40 miles per hour, with the ability to transport waste up to 1.2 miles away [13][15].

The system comprises an underground pipe network, vacuum stations, and a central facility where automation handles sorting and compacting. Real-time communication tools monitor fill levels to ensure efficiency [13]. To prevent waste streams from mixing, the system sequentially activates valves for different waste types - such as recyclables, organic waste, and general trash [13][15]. At the central terminal, waste is sorted automatically using cyclonic separation, compacted, and sealed into containers for transport to recycling plants or landfills [13][15]. Impressively, each inlet can process up to 660 pounds of waste per hour, operating continuously around the clock [15]. This streamlined approach not only accelerates waste collection but also sets the stage for transformative urban infrastructure improvements.

Countries like South Korea, Singapore, and Sweden have successfully implemented these systems, showcasing how sensor-equipped inlets and pneumatic pipes can revolutionize urban waste management [13][16].

Advantages of Pneumatic Systems

Pneumatic systems offer more than just operational speed - they bring substantial environmental and urban planning benefits. By cutting heavy vehicle traffic by 60% and reducing CO2 emissions from waste collection by 90%, these systems make a noticeable environmental impact [13][15]. As Rohan Bansal and Joydeep Bhattacharyya from Transforma Insights explain:

"The elimination of collection trucks is one of the major benefits of deploying vacuum tube systems as they can eliminate emissions caused by pick-up trucks by up to 90%." [13]

These systems also save valuable urban space, requiring just 15% of the surface area used by traditional waste collection infrastructure. This opens up opportunities for parks, housing, or commercial spaces [13]. Additionally, the sealed underground network minimizes vermin infestations by 30% and eliminates common issues like overflowing bins, odors, and pests. Unlike rigid truck-based schedules, pneumatic systems allow residents to dispose of waste at their convenience, improving hygiene and making waste management more user-friendly.

Implementation Considerations

Despite their advantages, the high upfront costs of installing underground pipe networks and central vacuum stations remain a key challenge [13]. The complexity of installation varies greatly: while new developments can seamlessly integrate pneumatic systems during the planning phase, retrofitting older neighborhoods requires significant excavation and coordination with existing utilities [13][14].

For established areas, successful adoption hinges on community cooperation and precise engineering. These systems demand specialized maintenance to ensure long-term reliability [13]. While the initial costs are steep, developers can offset expenses by utilizing the 85% of infrastructure space saved compared to conventional waste setups. This reclaimed space can be repurposed for additional housing, amenities, or commercial projects, adding long-term value [13]. Over time, operational savings from reduced labor, lower fuel consumption, and fewer maintenance needs for traditional waste systems help to offset the initial investment [14][15].

For municipalities, integrating pneumatic waste systems early in the planning stages of new high-density developments is a practical approach to minimize costs and streamline implementation [13].

Solar-Powered Trash Compactors

Solar-powered compactors provide an efficient above-ground alternative to underground pneumatic systems. These units harness solar energy through panels mounted on top to power an internal mechanism that compresses waste as it builds up. Equipped with sensors, they automatically activate the compaction process once the trash reaches a certain level [17]. This technology can reduce the volume of waste by as much as five times compared to traditional bins [25, 29].

At Iowa State University, this system significantly cut waste management expenses, dropping annual litter removal costs from $35,723 in 2008 to $19,846 by 2015. The university replaced 300 traditional concrete bins with 96 solar-powered compactors, which allowed them to switch from large trucks averaging 8 miles per gallon to smaller utility vehicles consuming just 5 gallons of gas weekly [17]. Merry Rankin, Director of Sustainability Programs at the university, highlighted the broader impact:

"This supports social sustainability by making the most efficient use of our teams' skills and expertise" [17].

Environmental Benefits

Solar-powered compactors contribute to a cleaner environment by reducing the frequency of waste collection by up to 80%, which in turn lowers emissions from collection vehicles [25, 28]. Traditional garbage trucks, which average only 8 miles per gallon, require fewer trips, directly reducing greenhouse gas emissions and improving air quality [17]. Additionally, the enclosed design of these compactors prevents litter from being scattered by the wind and keeps animals from accessing the trash [25, 26].

Running solely on solar energy, these compactors eliminate the need for external power sources, making them particularly useful in remote locations like parks, beaches, and areas where connecting to the electrical grid is either impractical or too expensive [25, 26]. The global market for solar-powered trash compactors was valued at approximately $250 million in 2024 and is expected to grow to $450 million by 2034, signaling increasing interest in sustainable urban infrastructure [18].

Much like sensor-driven and AI-enabled systems, solar-powered compactors simplify waste management while promoting eco-friendly urban development.

Operational Efficiency

Solar-powered compactors also enhance operational efficiency by incorporating advanced sensor technology. These sensors send real-time data on fill levels to a central management system, allowing waste collection teams to dispatch trucks only when bins are nearly full, rather than following fixed schedules [25, 27]. This approach optimizes routes, reduces fuel consumption, and lowers vehicle maintenance costs [26, 31].

In October 2023, Bigbelly Solar partnered with a leading urban waste management company to roll out smart solar-powered compactors across cities in North America. Using real-time data analytics, this initiative aims to streamline collection routes and cut operational expenses [18]. That same year, Ecube Labs introduced the CleanCube 3000, a model equipped with upgraded sensors and a mobile app for remote monitoring and performance tracking [18].

Although the initial investment for these compactors can be significant, cities can recoup costs over time through savings on labor, fuel, and vehicle upkeep [17]. Additionally, these units can be integrated into broader smart infrastructure plans, serving as multifunctional hubs that monitor air quality, noise levels, or even foot traffic patterns [19].

Automated Waste Collection Vehicles

With the integration of sensors and AI-driven technologies, automated waste collection vehicles are transforming the way trash is managed. These trucks combine robotic arms, AI-powered navigation, and real-time data systems to make operations more efficient and safer for workers. A standout feature is the Automated Side Loading (ASL) arm, which allows drivers to operate a mechanical arm from inside the cab using a joystick. This eliminates the need for workers to manually handle bins or navigate busy traffic on foot, significantly improving safety [3]. Additionally, these vehicles leverage AI-driven route optimization, using algorithms such as Genetic Algorithms and Reinforcement Learning to analyze data from IoT-enabled smart bins. This ensures the most fuel- and time-efficient collection routes [1].

For instance, Miami-Dade County in Florida introduced a fully electric garbage truck equipped with ASL technology [3]. Similarly, Volvo has piloted an autonomous refuse truck in Sweden that uses lidar for obstacle detection and preprogrammed routes, optimizing gear shifts and steering to reduce emissions [3].

Key Technologies

A host of advanced technologies drives the functionality of these automated vehicles. Lidar, GPS, and computer vision are essential for autonomous navigation, enabling trucks to map routes, detect obstacles, and operate without direct human control [3][20]. Cameras installed on trucks can identify overflowing bins, potholes, and infrastructure issues in real time, feeding valuable data into management systems for better operational planning [3][20]. For example, in Cambridge, Massachusetts, five garbage trucks were equipped with air-quality sensors and infrared cameras to gather urban data during their daily routes [3].

IoT connectivity, using systems like LoRaWAN, GPRS, and RFID, ensures constant communication between vehicles, waste bins, and central monitoring stations. This technology monitors bin fill levels and tracks vehicle locations [4][5]. Telematics systems further enhance efficiency by providing fleet managers with detailed performance metrics, enabling them to adjust routes dynamically and respond to service requests more effectively. In another innovative step, the German company Angsa Robotics raised €2.5 million to develop an autonomous waste collection robot with an 8-hour battery life, designed specifically for parks and large events [20]. These technologies exemplify the powerful intersection of robotics and IoT in modern urban services.

Pros and Cons

While automated waste collection vehicles bring numerous advantages, they also come with certain challenges. For example, in 2021, Mount Airy, North Carolina, purchased a semi-automated garbage truck for $760,000, aiming to reduce costs by phasing out some collector roles through attrition [3]. All-electric trucks with ASL technology are also projected to save approximately $16,000 annually in fuel and maintenance costs [3].

Feature | Advantages | Disadvantages |

|---|---|---|

Labor | Keeps workers safely in the cab, reducing manual labor [3] | May lead to job displacement or role shifts [3] |

Efficiency | Optimized routes cut fuel use, emissions, and wear-and-tear [1][3] | High initial costs compared to traditional trucks [3] |

Safety | Limits worker exposure to traffic, sharp objects, and heavy lifting [3] | Advanced sensors and robotics require specialized maintenance [3] |

Sustainability | Supports zero-emission goals when combined with electric drivetrains [3] | Full autonomy depends on high-quality mapping and infrastructure [3] |

The National Academies of Sciences, Engineering, and Medicine highlights the safety benefits of automation:

"The ASL arm avoids the need for workers to be exposed to traffic and other hazards associated with the traditional hands-on method of emptying bins" [3].

Although the upfront costs of these vehicles can be steep, cities often recover their investment through reduced labor expenses, lower fuel consumption, and a decrease in workplace injuries over time.

The Future of Automated Waste Systems

Automated waste technologies are poised to reshape how cities manage waste. With 70% of waste currently ending up in landfills and only 19% being recycled, the global cost of inefficient waste management has reached an estimated $640 billion annually. By 2050, waste generation is expected to hit an overwhelming 4.54 billion tons [1]. However, advancements in AI, robotics, IoT sensors, and autonomous vehicles present an opportunity to reverse these trends, reduce emissions, and cut operational expenses.

Future waste systems will harness cutting-edge AI to analyze complex waste patterns and predict collection needs with precision [1]. Hyperspectral cameras and computer vision, integrated with robotics, will make it possible to identify and sort materials more accurately. This is especially crucial for handling challenging materials like film plastics and multilayered packaging, which still require manual sorting [1][21]. Additionally, LoRaWAN has emerged as the preferred communication protocol for urban smart bin networks due to its ability to cover long distances while consuming minimal power [4]. These innovations are paving the way for fully autonomous waste collection systems.

Autonomous waste collection fleets are already making headway. Leading waste management companies have announced plans to ensure that 50% of their new truck purchases will be electric or semi-automated by 2028 [3]. These vehicles will rely on Lidar technology and optimized preprogrammed routes, which will significantly reduce emissions and fuel costs. Meanwhile, cities are experimenting with decentralized solutions, such as Autonomous Mobile Robots (AMRs) for localized waste collection and modular smart composters for residential organic waste [2].

But the future of waste management isn’t just about collection - it’s about redefining waste as a resource. Advanced systems will go beyond sorting and recycling to convert waste into renewable energy sources. Organic waste, for instance, will increasingly be transformed into sustainable aviation fuel (SAF), biogas, and biohydrogen [1]. This shift not only aligns with environmental goals but also generates economic value from materials that would otherwise contribute to the projected 2.38 billion tons of CO2-equivalent emissions annually by 2050 if left unmanaged [1].

Organizations like Council Fire (https://councilfire.org) are helping municipalities and companies adopt these technologies. By aligning financial, environmental, and social priorities, they aim to create waste management systems that benefit both urban and rural communities. Achieving this vision requires phased implementation, active public participation, and data-driven strategies. These efforts promise to build waste systems that support both people and the planet, advancing sustainability in meaningful ways.

FAQs

How do IoT sensors make waste collection more efficient?

IoT sensors are revolutionizing waste collection by turning standard bins into smart, connected devices. These sensors keep tabs on fill levels, temperature, and location in real time, transmitting this data through low-power wireless networks. With this technology, waste operators can pinpoint which bins are full and exactly where they are, allowing crews to focus solely on bins that need attention. This targeted approach not only reduces unnecessary stops but also saves fuel, cuts down on vehicle wear and tear, and lowers labor expenses.

Beyond real-time tracking, predictive analytics adds another layer of efficiency by forecasting when bins are likely to overflow. This enables dynamic routing, allowing operators to optimize collection routes and reduce total driving distances. Continuous monitoring also helps identify the best spots for bin placement and ensures timely maintenance, which lowers operational costs and boosts recycling efforts.

Setting up IoT sensor systems, however, demands thoughtful planning and collaboration. Council Fire partners with municipalities and private waste services to design and implement these networks, ensuring they meet sustainability objectives while staying within budget.

What are the environmental advantages of pneumatic waste collection systems?

Pneumatic waste collection systems bring a fresh approach to managing waste, replacing traditional garbage trucks with underground, vacuum-powered pipelines. This shift not only cuts down on vehicle traffic and noise but also significantly reduces carbon emissions. Compared to diesel-powered trucks, these systems consume less energy, making them a more efficient alternative.

By keeping streets cleaner, they help prevent litter and runoff, which protects stormwater systems from contamination. Their sealed design also limits the release of methane and other harmful gases during transport, improving air quality and lessening their overall environmental footprint. Additionally, these systems centralize waste management, streamlining efforts to integrate recycling and composting. The result? Higher material recovery rates and less reliance on landfills.

Council Fire collaborates with municipalities and developers to evaluate these benefits and implement pneumatic waste solutions that align with long-term goals like achieving carbon neutrality and creating resilient urban spaces.

How do AI-powered robots improve recycling efficiency and accuracy?

AI-driven recycling robots leverage computer vision and machine learning to accurately identify and sort materials such as plastic, paper, glass, metal, and cardboard with an impressive accuracy rate exceeding 95%. By automating what has traditionally been a manual process, these robots drastically cut down on human errors and reduce contamination in recycling streams.

Beyond improving sorting accuracy, these robots play a crucial role in optimizing waste management systems. They boost material recovery rates and reduce the amount of waste sent to landfills, streamlining the recycling process and making it more efficient.

Related Blog Posts

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Jan 2, 2026

Automated Waste Systems: Key Technologies

Sustainability Strategy

In This Article

IoT, AI, robotics, pneumatic networks and solar compactors are reshaping urban waste collection—cutting emissions, costs, and boosting recycling efficiency.

Automated Waste Systems: Key Technologies

Automated waste systems are transforming how cities manage the growing challenge of waste production, which is expected to reach 4.54 billion tons annually by 2050. These systems integrate IoT sensors, AI, robotics, and other technologies to improve efficiency, reduce emissions, and lower operational costs. Key advancements include:

IoT Sensors: Monitor bin fill levels in real-time, optimizing collection routes and reducing fuel use by up to 29%.

AI-Powered Recycling Robots: Sort recyclables with up to 84% accuracy, processing materials faster and cutting contamination by 40%.

Pneumatic Waste Systems: Use underground pipelines to transport waste, reducing truck traffic by 60% and emissions by 90%.

Solar-Powered Trash Compactors: Compress waste using solar energy, reducing collection trips by 80%.

Automated Waste Vehicles: Equipped with robotic arms and AI for safer, more efficient collection.

These technologies are reshaping urban waste management by optimizing processes, improving safety, and supporting broader sustainability goals. The market for automated waste solutions is projected to grow from $389.46 million in 2024 to $651.46 million by 2030, reflecting increasing adoption worldwide.

5 Key Automated Waste Technologies: Features, Benefits & Impact Statistics

The Envac System - Automated waste collection for smart cities

IoT Sensors for Real-Time Waste Monitoring

IoT sensors are transforming waste management by offering real-time insights into bin fill levels. These sensors, often ultrasonic or infrared, are installed inside waste containers to measure the distance to the waste surface, allowing for precise calculation of how full the bin is. When a bin reaches a set capacity - commonly 80% - the system notifies dispatchers to schedule a pickup [6][7]. This approach eliminates the inefficiencies of traditional fixed-route collection, where trucks either visit bins that are only partially full or miss bins that are already overflowing.

In addition to monitoring fill levels, advanced camera-based sensors leverage computer vision and AI to detect issues like recycling contamination or illegal dumping, enabling timely interventions [6][1]. GPS modules integrated into bins and collection vehicles provide exact location data, allowing managers to map out containers and monitor truck routes in real time [6][4]. Data collected by these sensors is transmitted through technologies like LoRaWAN, GSM, or Wi-Fi to cloud platforms, where route optimization engines dynamically adjust collection schedules [6][8].

The benefits are clear. A large-scale pilot in Lahore, Pakistan, conducted in July 2024, utilized ultrasonic sensors and LoRaWAN to process over 200 million data points. The results were impressive: a 32% improvement in route efficiency, a 29% reduction in fuel consumption and emissions, and 18% savings on vehicle maintenance [8]. For U.S. cities, cutting route miles by just 10% to 15% can result in annual savings in the six-figure range [6].

Advantages of IoT Sensors

The advantages of IoT sensors go well beyond fuel savings. Dynamic routing based on real-time data eliminates unnecessary trips to empty bins, reducing mileage and wear on vehicles and roads [6][8]. For example, in 2023, Columbus, Ohio, managed to cut bulk-item collection stops by over 15%, saving four hours of staff time weekly and delaying the need for additional truck purchases [6].

These systems also enhance resource management by predicting staffing needs and reallocating trucks during peak times or seasonal spikes [6]. Camera-based sensors provide continuous monitoring of recycling compliance, replacing occasional manual inspections with automated oversight [6]. Harold Mitchell, a consultant at Raftelis Financial Consultants, highlights the broader implications:

"When waste systems talk - through sensors, telematics, dashboards, and utility data connections - smart communities can listen, learn, and iterate to make improvements quickly" [6].

Some cities are even linking waste management platforms with water and electric utility data to identify vacant properties and avoid unnecessary stops [6]. This integration is reshaping urban operations, turning waste collection into a key component of a more interconnected smart-city ecosystem. The move from static paper maps to live GIS dashboards that update in real time on driver tablets marks a significant shift in how municipalities manage their services [6].

Challenges of IoT Sensors

Despite the clear benefits, deploying IoT systems city-wide is not without challenges. High initial costs for sensors, network infrastructure, and software can be a major hurdle, especially for smaller municipalities [6][8]. Power and battery life are additional concerns; sensors require consistent energy sources, and frequent battery replacements can drive up operational costs [8][4]. Wireless technologies like Wi-Fi and Zigbee also face limitations in range and struggle with obstacles in dense urban settings [4].

Data security is another critical issue. IoT systems are susceptible to jamming, spoofing, and data breaches, necessitating robust encryption methods such as AES for LoRaWAN and TLS for cellular and cloud communications [8]. Many cities also face difficulties integrating IoT data with existing platforms like 311 services, GIS maps, or utility databases. Achieving seamless integration requires careful coordination across operations, finance, and IT departments [6][8]. As Mitchell puts it:

"Implementing IoT in waste management is not a silver bullet. It requires investment, detailed planning (operations, finance, and IT capabilities), integration, and training" [6].

Durability is another concern. Sensors must endure harsh conditions, such as extreme weather, physical damage, and exposure to corrosive waste. To address this, many cities have adopted solar-powered ultrasonic sensors, which offer extended operational life [6][8][4]. The adoption of LoRaWAN as the preferred communication protocol has also helped overcome connectivity challenges. LoRaWAN provides long-range coverage - between 2 and 5 kilometers - while consuming minimal power, making it particularly suitable for urban waste systems [8][4]. By using a hierarchical setup where sensors communicate with gateways via LoRaWAN and only aggregated data is sent through cellular networks, cities can keep transmission costs low without compromising reliability [8].

While these challenges highlight the complexities of IoT adoption, they also pave the way for further advancements, which will be explored in the next section on AI-powered recycling robots.

AI-Powered Recycling Robots

AI-powered recycling robots are revolutionizing material recovery facilities (MRFs) by employing advanced sensors and machine learning to sort recyclables with remarkable precision. Equipped with high-resolution cameras, hyperspectral imaging, and near-infrared sensors, these systems can identify materials based on their chemical makeup and immediately direct them into the correct recycling streams [11][9].

The efficiency of these robots far surpasses human capabilities. While a human worker typically sorts 50–80 items per hour, AI robots can process up to 1,000 items per hour, operating continuously with over 99% uptime [11]. This translates to a 50% increase in facility operating hours compared to human labor, all while addressing challenges like staffing shortages and high turnover rates [11].

Advancements in deep reinforcement learning frameworks, such as QT-Opt, further enhance these systems. For example, Google Research deployed 23 reinforcement learning-enabled robots between 2021 and 2022, conducting 540,000 trials in controlled environments and 32,500 trials in real-world conditions. These efforts resulted in an 84% sorting accuracy and a 40–50% reduction in bin contamination [10]. As researchers noted:

"The final system could accurately sort about 84% of the objects on average, with performance increasing steadily as more data was added" [10].

Case Studies of AI Robots

Real-world applications highlight the transformative impact of AI robots in recycling. Midwest Recycling Service, for instance, implemented Waste Robotics’ automated construction and demolition (C&D) sorting line. With three robotic arms in operation, the facility now achieves over 90% material capture. As President Justin Rice shared:

"Now, with three sorting arms, we achieve over 90% capture" [9].

In France, Altriom 2.0 integrated a Waste Robotics hyperspectral system to tackle the challenge of sorting visually similar but chemically distinct materials. This AI-driven system successfully identified all incoming materials, delivering high-purity sorted streams. Operations Manager Hugo Simme remarked:

"Waste Robotics helped us overcome a challenge with complex materials. Thanks to their hyperspectral system and AI implemented in the material detection system, we succeeded in identifying all the materials arriving on our line, achieving high-quality sorting" [9].

Closer to home, Alameda County Industries near San Francisco saw labor costs drop by 59% after adopting AI robots. These machines operate consistently around the clock, and their leasing costs are roughly equivalent to the annual salaries of one to two workers, making them a cost-effective solution even for mid-sized facilities [11].

Impact on Recycling Efficiency

The introduction of AI-powered robots has significantly improved recycling efficiency. Facilities report a 60% boost in overall productivity and a 35% reduction in worker injuries, as robots handle hazardous materials that would otherwise pose risks to human sorters [11]. Additionally, contamination in recycling streams has decreased by nearly 40%, ensuring more materials meet the purity standards required by manufacturers [11].

While current MRFs capture about 87% of accepted recyclables, AI-driven systems are pushing these rates even higher. Automated sorting now achieves 96% capture rates for steel cans and 93% for HDPE bottles and jars [12]. This progress helps reduce the estimated 30% of potentially valuable recyclables lost to landfills due to human error or outdated equipment [11]. In North America alone, 340 waste facilities have already been upgraded with AI technology, and adoption is expected to grow at an annual rate of 22% through 2030 [11].

Advanced systems like Greyparrot can now classify waste into 111 distinct categories, while AMP ONE identifies over 50 categories [11]. Some systems even recognize specific brand logos on packaging, opening the door for corporate accountability in managing packaging waste [11]. By producing higher-purity recycled materials, AI robots are creating stronger markets for recycled goods and reducing dependence on virgin resources, making them a cornerstone of modern waste management practices.

Pneumatic Waste Systems

Expanding on advancements like sensor-driven and robotic waste solutions, pneumatic waste systems present a futuristic underground alternative. Often referred to as Automated Vacuum Collection Systems (AVCS), these setups rely on underground pipelines and negative air pressure to move waste from street-level inlets directly to a central processing facility. Here’s how it works: residents drop their trash into designated inlets equipped with temporary valves. When triggered, vacuum pumps generate negative pressure, propelling waste through the network of pipes at speeds reaching 40 miles per hour, with the ability to transport waste up to 1.2 miles away [13][15].

The system comprises an underground pipe network, vacuum stations, and a central facility where automation handles sorting and compacting. Real-time communication tools monitor fill levels to ensure efficiency [13]. To prevent waste streams from mixing, the system sequentially activates valves for different waste types - such as recyclables, organic waste, and general trash [13][15]. At the central terminal, waste is sorted automatically using cyclonic separation, compacted, and sealed into containers for transport to recycling plants or landfills [13][15]. Impressively, each inlet can process up to 660 pounds of waste per hour, operating continuously around the clock [15]. This streamlined approach not only accelerates waste collection but also sets the stage for transformative urban infrastructure improvements.

Countries like South Korea, Singapore, and Sweden have successfully implemented these systems, showcasing how sensor-equipped inlets and pneumatic pipes can revolutionize urban waste management [13][16].

Advantages of Pneumatic Systems

Pneumatic systems offer more than just operational speed - they bring substantial environmental and urban planning benefits. By cutting heavy vehicle traffic by 60% and reducing CO2 emissions from waste collection by 90%, these systems make a noticeable environmental impact [13][15]. As Rohan Bansal and Joydeep Bhattacharyya from Transforma Insights explain:

"The elimination of collection trucks is one of the major benefits of deploying vacuum tube systems as they can eliminate emissions caused by pick-up trucks by up to 90%." [13]

These systems also save valuable urban space, requiring just 15% of the surface area used by traditional waste collection infrastructure. This opens up opportunities for parks, housing, or commercial spaces [13]. Additionally, the sealed underground network minimizes vermin infestations by 30% and eliminates common issues like overflowing bins, odors, and pests. Unlike rigid truck-based schedules, pneumatic systems allow residents to dispose of waste at their convenience, improving hygiene and making waste management more user-friendly.

Implementation Considerations

Despite their advantages, the high upfront costs of installing underground pipe networks and central vacuum stations remain a key challenge [13]. The complexity of installation varies greatly: while new developments can seamlessly integrate pneumatic systems during the planning phase, retrofitting older neighborhoods requires significant excavation and coordination with existing utilities [13][14].

For established areas, successful adoption hinges on community cooperation and precise engineering. These systems demand specialized maintenance to ensure long-term reliability [13]. While the initial costs are steep, developers can offset expenses by utilizing the 85% of infrastructure space saved compared to conventional waste setups. This reclaimed space can be repurposed for additional housing, amenities, or commercial projects, adding long-term value [13]. Over time, operational savings from reduced labor, lower fuel consumption, and fewer maintenance needs for traditional waste systems help to offset the initial investment [14][15].

For municipalities, integrating pneumatic waste systems early in the planning stages of new high-density developments is a practical approach to minimize costs and streamline implementation [13].

Solar-Powered Trash Compactors

Solar-powered compactors provide an efficient above-ground alternative to underground pneumatic systems. These units harness solar energy through panels mounted on top to power an internal mechanism that compresses waste as it builds up. Equipped with sensors, they automatically activate the compaction process once the trash reaches a certain level [17]. This technology can reduce the volume of waste by as much as five times compared to traditional bins [25, 29].

At Iowa State University, this system significantly cut waste management expenses, dropping annual litter removal costs from $35,723 in 2008 to $19,846 by 2015. The university replaced 300 traditional concrete bins with 96 solar-powered compactors, which allowed them to switch from large trucks averaging 8 miles per gallon to smaller utility vehicles consuming just 5 gallons of gas weekly [17]. Merry Rankin, Director of Sustainability Programs at the university, highlighted the broader impact:

"This supports social sustainability by making the most efficient use of our teams' skills and expertise" [17].

Environmental Benefits

Solar-powered compactors contribute to a cleaner environment by reducing the frequency of waste collection by up to 80%, which in turn lowers emissions from collection vehicles [25, 28]. Traditional garbage trucks, which average only 8 miles per gallon, require fewer trips, directly reducing greenhouse gas emissions and improving air quality [17]. Additionally, the enclosed design of these compactors prevents litter from being scattered by the wind and keeps animals from accessing the trash [25, 26].

Running solely on solar energy, these compactors eliminate the need for external power sources, making them particularly useful in remote locations like parks, beaches, and areas where connecting to the electrical grid is either impractical or too expensive [25, 26]. The global market for solar-powered trash compactors was valued at approximately $250 million in 2024 and is expected to grow to $450 million by 2034, signaling increasing interest in sustainable urban infrastructure [18].

Much like sensor-driven and AI-enabled systems, solar-powered compactors simplify waste management while promoting eco-friendly urban development.

Operational Efficiency

Solar-powered compactors also enhance operational efficiency by incorporating advanced sensor technology. These sensors send real-time data on fill levels to a central management system, allowing waste collection teams to dispatch trucks only when bins are nearly full, rather than following fixed schedules [25, 27]. This approach optimizes routes, reduces fuel consumption, and lowers vehicle maintenance costs [26, 31].

In October 2023, Bigbelly Solar partnered with a leading urban waste management company to roll out smart solar-powered compactors across cities in North America. Using real-time data analytics, this initiative aims to streamline collection routes and cut operational expenses [18]. That same year, Ecube Labs introduced the CleanCube 3000, a model equipped with upgraded sensors and a mobile app for remote monitoring and performance tracking [18].

Although the initial investment for these compactors can be significant, cities can recoup costs over time through savings on labor, fuel, and vehicle upkeep [17]. Additionally, these units can be integrated into broader smart infrastructure plans, serving as multifunctional hubs that monitor air quality, noise levels, or even foot traffic patterns [19].

Automated Waste Collection Vehicles