Dec 22, 2025

Dec 22, 2025

Industrial Symbiosis in North America: Case Studies

Sustainability Strategy

Sustainability Strategy

In This Article

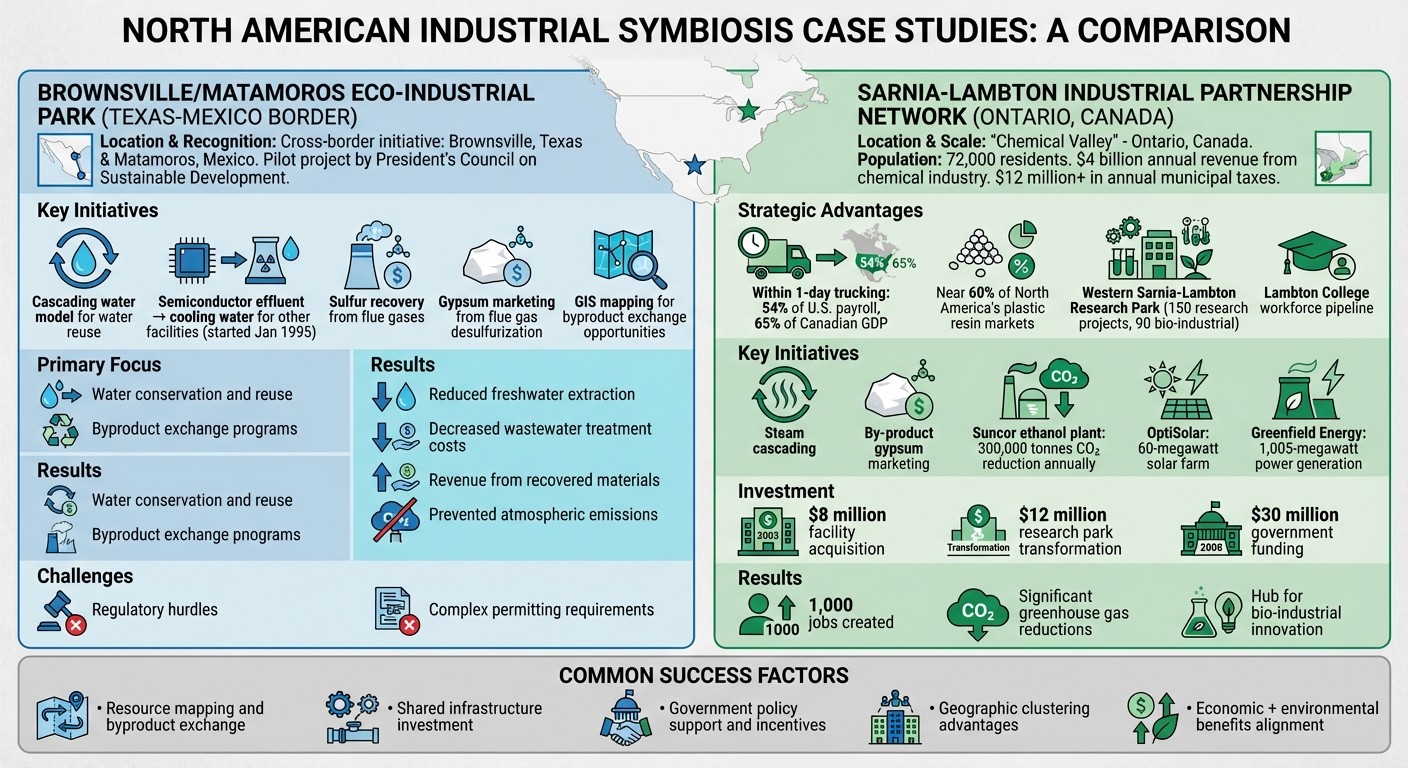

Two North American case studies on industrial symbiosis: water reuse, byproduct exchanges, shared infrastructure and policies that cut costs, emissions, and create revenue.

Industrial Symbiosis in North America: Case Studies

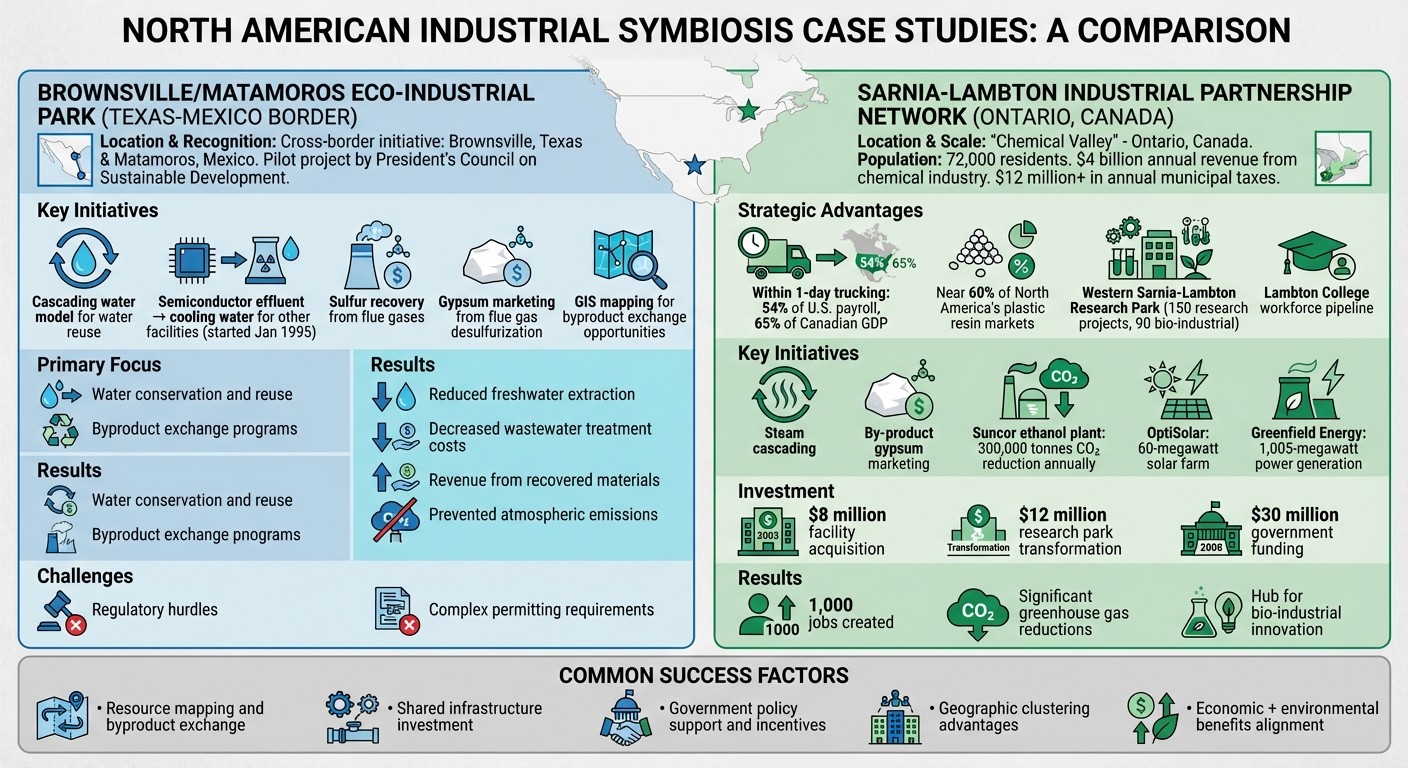

Industrial symbiosis turns waste into resources, creating value for businesses and communities. This article examines two North American examples: the Brownsville/Matamoros Eco-Industrial Park and the Sarnia-Lambton Industrial Partnership Network. Both showcase how collaboration among industries can reduce waste, conserve resources, and generate economic benefits.

Key Insights:

Brownsville/Matamoros Eco-Industrial Park: Focuses on water reuse and byproduct exchange. Initiatives like cascading water systems and sulfur recovery have cut costs and reduced waste.

Sarnia-Lambton Industrial Partnership Network: Located in Ontario’s “Chemical Valley,” it leverages its geographic and research advantages to integrate bio-industrial innovation and renewable energy projects.

These efforts highlight how industries can align resource use with financial and operational goals, supported by government incentives and shared infrastructure. The results include reduced emissions, lower costs, and new revenue streams, proving that industrial symbiosis benefits businesses and the environment alike.

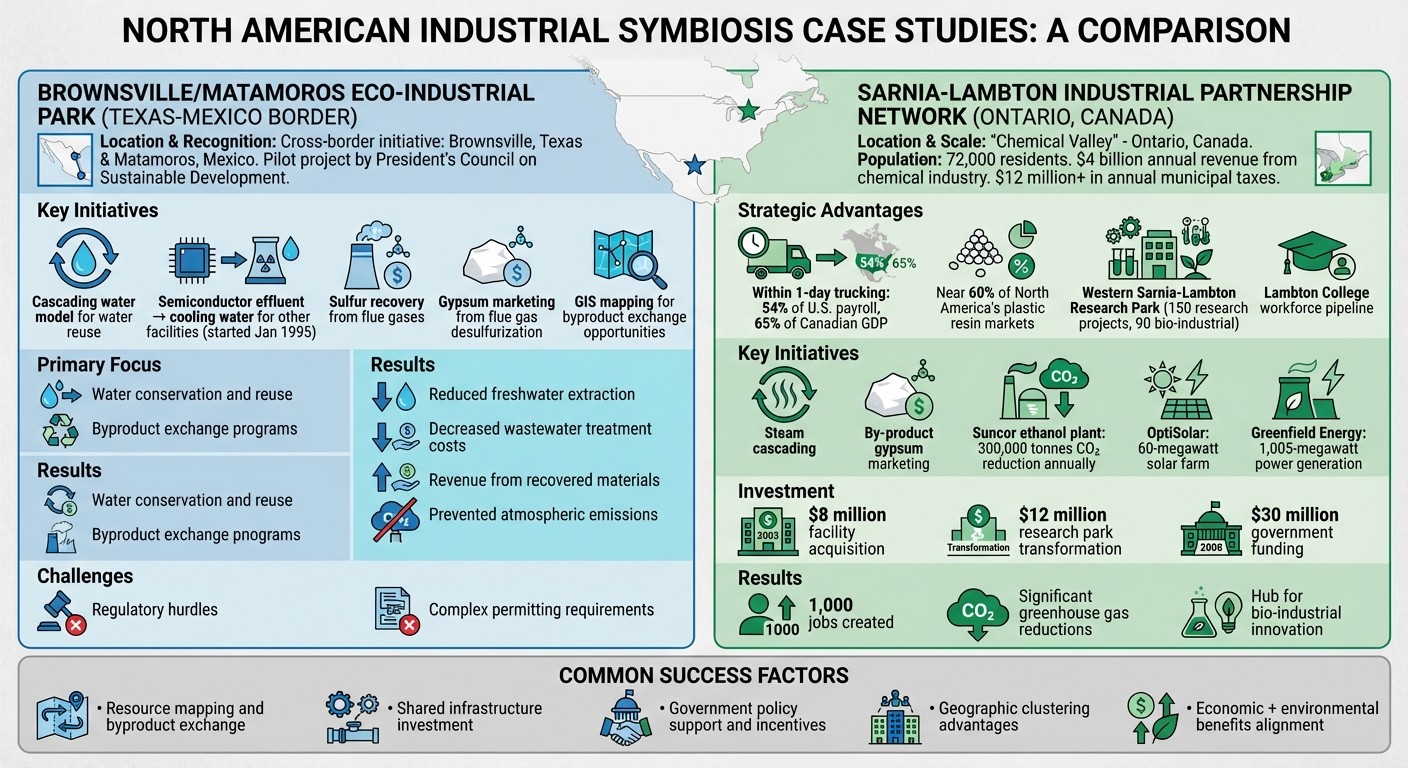

Brownsville-Matamoros vs Sarnia-Lambton Industrial Symbiosis Comparison

Inside the world of industrial symbiosis | The origins of the circular economy

Case Study 1: Brownsville/Matamoros Eco-Industrial Park

The Brownsville/Matamoros Eco-Industrial Park represents a unique cross-border initiative between Brownsville, Texas, and Matamoros, Mexico. Recognized as a pilot project by the President's Council on Sustainable Development, this effort brought together the City of Brownsville, the Port of Brownsville, and the Brownsville Economic Development Council (BEDC). Their shared goal was to explore how industrial byproducts could be repurposed as resources instead of being treated as waste [4].

Park Design and Operations

A key focus of the park’s design is water conservation and reuse, achieved through a cascading water model. Local industries, which consume water on a scale comparable to municipal levels, benefit significantly from this approach [4]. In January 1995, the Brownsville Public Utilities Board introduced a system where high-quality effluent from semiconductor plants is reused as cooling water for other industrial facilities. This initiative has reduced the need for freshwater extraction [4][5].

The park also implemented several byproduct exchange programs. For instance, the Brownsville Refinery Corporation successfully recovered sulfur from flue gases and marketed gypsum derived from flue gas desulfurization to companies such as U.S. Gypsum. These efforts turned potential pollutants into valuable industrial inputs. Additionally, Geographic Information Systems (GIS) were used to combine water usage data with geographic information, helping identify new opportunities for byproduct exchanges [4][5].

These strategies have led to measurable economic and environmental improvements, as outlined below.

Measured Economic and Environmental Results

The economic advantages of water reuse are evident in the reduced costs associated with wastewater treatment. The cascading water model not only minimized the extraction of freshwater but also decreased the volume of wastewater requiring disposal [4][5]. Similarly, sulfur recovery and gypsum marketing efforts prevented harmful atmospheric emissions while creating revenue from materials that would otherwise be discarded [5]. Other initiatives, such as repurposing fly ash from power plants for construction and recycling solvents to cut down on hazardous waste, further underscore the project's impact.

However, despite these achievements, regulatory hurdles have posed challenges. Strict waste classifications and complex permitting requirements have slowed the implementation of some planned byproduct exchanges in the region [5]. The groundwork for these efforts was laid in a 1994 feasibility study conducted by Indigo Development in partnership with the U.S. EPA, which set the stage for these innovative collaborations [4].

Case Study 2: Sarnia-Lambton Industrial Partnership Network

The Sarnia-Lambton region in Ontario, Canada, often referred to as Canada's Chemical Valley, stands out as a prime example of industrial symbiosis in action. With its chemical industry generating over $4 billion in annual revenue and contributing more than $12 million in municipal taxes each year, this area, home to about 72,000 residents, has become a North American leader in industrial ecology [8]. This case highlights how diverse approaches to industrial symbiosis can thrive in North America.

Key Factors Behind Sarnia-Lambton's Success

The region's achievements are rooted in a combination of strategic advantages. Its location is a significant factor - within a one-day trucking distance of 54% of the U.S. payroll and 65% of Canadian GDP, as well as proximity to 60% of North America's plastic resin markets. This geographic positioning fosters competitive collaboration [8]. John Margeson, Senior Industry Officer at Industry Canada, summed it up well:

"Petrochemical companies normally like to be part of an industry cluster because this allows product and by‐product streams to be exchanged between sites, improving overall competitiveness. One company's by‐product can become another's feedstock" [8].

The region also benefits from robust technical and research infrastructure. The Western Sarnia-Lambton Research Park and Bioindustrial Innovation Canada serve as bridges between traditional petrochemical industries and emerging sectors like biochemical and clean energy [6]. An important milestone came in 2003, when Lambton's Community Development Corporation acquired a 200,000-square-foot former Dow Chemical facility for $8 million. An additional $12 million investment transformed it into the University of Western Ontario Sarnia-Lambton Research Park, which now oversees 150 research projects, 90 of which focus on bio-industrial innovation [8]. The region's workforce is supported by Lambton College, which ensures a steady supply of skilled professionals [8]. Together, these resources have established Sarnia-Lambton as a hub for ongoing advancements in industrial symbiosis.

Outcomes from the Bruce Energy Centre

The Bruce Energy Centre demonstrates how these factors translate into tangible results. The region's industrial symbiosis is evident in initiatives like steam cascading and the marketing of by-product gypsum [7]. Suncor Energy's ethanol plant, once the largest in Canada, has reduced CO2 emissions by 300,000 tonnes annually [8]. Additionally, the area has attracted significant renewable energy projects, such as OptiSolar's 60-megawatt solar farm and Greenfield Energy's 1,005-megawatt power generation facility, both aimed at cutting greenhouse gas emissions [8]. In February 2008, federal and provincial governments each contributed $15 million to launch a bio-industrial innovation center, a project expected to create 1,000 jobs [8].

Design Principles for Eco-Industrial Parks

Eco-industrial parks thrive on strategies that turn waste into valuable resources, creating a cycle of efficiency and sustainability. A foundational approach is resource mapping, which involves tracking flows of energy, water, and materials in real time. This process uncovers opportunities for companies to exchange resources, reducing waste and improving efficiency. As Jonathan S. Krones from Yale University explains:

"The practice of turning byproducts into the valuable inputs of another industry is as ancient as economic development itself" [1].

Another key to success is shared infrastructure, where participants jointly invest in systems like renewable energy sources, water treatment facilities, and district heating networks. This collaborative approach not only lowers costs but also minimizes environmental impact. Contracts within these parks often:

"decouple the quantity of waste disposed from the contractor's profit by providing financial incentives for services related to material consumption, use and recovery" [1].

The development style of eco-industrial parks also matters. For instance, Denmark's Kalundborg network evolved organically over time without a rigid master plan, while some U.S. parks, designed with strict guidelines, have faced challenges [9]. Successful models in North America strike a balance between structured planning and the flexibility to allow organic relationships to develop naturally. These principles form the backbone of the design process detailed below.

Steps for Designing Eco-Industrial Parks

The first step in designing an eco-industrial park is resource mapping, leveraging tools like sensors and data analytics to identify inefficiencies and potential symbiotic exchanges. This step uncovers opportunities that isolated operations might overlook.

Next, stakeholder alignment is crucial. Building networks with local governments and utilities can provide regulatory support and incentives, ensuring all parties work toward shared goals.

Designing shared infrastructure comes next. This includes systems for renewable energy, waste-to-energy conversion, and water treatment. To ensure long-term success, governance structures - such as collaborative management and joint ownership models - should be established to distribute benefits fairly and maintain stability.

Finally, performance must be monitored continuously. Using economic, environmental, and social indicators, parks can track progress and demonstrate returns on investment, keeping stakeholders engaged and committed.

Measuring Performance in Eco-Industrial Parks

Performance evaluation in eco-industrial parks typically focuses on three main indicators:

Economic: Metrics like cost savings, revenue from by-product sales, and job creation.

Environmental: Indicators such as waste reduction, emissions cuts, and resource conservation.

Social: Measures including community health improvements, workforce development, and local economic benefits.

Quantitative tools like Material Flow Analysis, Life Cycle Assessment, and Environmentally Extended Input-Output Analysis are often employed to assess these outcomes [3].

Real-world examples show that systematic performance measurement not only enhances resource efficiency but also boosts economic returns, proving the value of these collaborative ecosystems.

Government Support for Industrial Symbiosis

Government policies and incentives play a key role in advancing industrial symbiosis, turning eco-industrial parks into thriving operational centers. Without such support, companies often find it difficult to justify the initial costs associated with symbiotic practices. These efforts complement the strategic designs and operational advancements that underpin successful industrial ecosystems.

Policy and Regulatory Frameworks

State and federal policies serve as a backbone for industrial symbiosis, offering both guidance and financial incentives. For instance, Washington's SB 5345, enacted in May 2021, and federal programs like the President's Council on Sustainable Development (PCSD) provide essential support. Washington State's legislation, managed by the Department of Commerce, offers practical guidance and proven strategies for industrial symbiosis. It also includes a grant program aimed at bolstering local waste coordination efforts [10].

Tax incentives further enhance these initiatives. Across North America, local governments now provide tax breaks to companies that successfully divert waste through symbiotic collaborations [10].

At the federal level, the President's Council on Sustainable Development (PCSD), established on June 29, 1993, legitimized eco-industrial development in the U.S. by fostering cooperation among industries, governments, and environmental organizations [11].

Infrastructure Funding and Incentives

Government investment in infrastructure development has proven to deliver tangible outcomes. For example, Environment Canada supported the creation of the Burnside Eco-Industrial Park in Nova Scotia, showcasing a pilot industrial ecosystem [11]. Similarly, the Town of Cape Charles and Northampton County, Virginia, co-sponsored the Port of Cape Charles Sustainable Technologies Industrial Park [11].

These examples highlight that government involvement extends beyond financial support, encompassing planning, technical expertise, and a long-term commitment to fostering sustainable industrial practices.

Council Fire's Work in Industrial Symbiosis

Council Fire takes industrial symbiosis from concept to action by combining government incentives and thoughtful design with tangible results. Their systems-thinking approach helps organizations transition from sustainability planning to actionable strategies. Collaborating with companies, governments, and nonprofits across North America, they design and implement eco-industrial parks that deliver both environmental improvements and economic gains.

Their process integrates energy mapping with detailed financial modeling to ensure every symbiotic exchange makes economic sense. By conducting in-depth technical and financial analyses, Council Fire evaluates energy-sharing opportunities, projects return on investment (ROI), and develops scalable energy systems suited to specific industrial needs. This approach enables effective resource recovery, laying the groundwork for eco-industrial success. For instance, their work on the Sarnia-Lambton Eco-Industrial Park focuses on refining renewable energy integration and resource management to significantly reduce carbon emissions.

What sets Council Fire apart is their hands-on involvement in project execution. Rather than simply producing compliance reports, they turn sustainability goals into actionable steps using data-driven insights and by aligning stakeholders. From initial feasibility studies to performance measurement, their efforts include developing communication strategies that build trust and encourage collaboration among all parties involved.

Their work underscores that industrial symbiosis is about more than technical know-how. It requires strategic coordination, robust financial planning, and the ability to turn ambitious environmental objectives into practical, operational outcomes that deliver lasting benefits for everyone involved.

Key Takeaways

Industrial symbiosis delivers tangible results. Take the Casella-Hypertherm partnership as an example: between 2010 and 2014, they managed to cut disposed waste by nearly half, dropping from 191 to 98 metric tons. They also reduced their disposal rate from 14% to just 4.4%. By focusing on targeted interventions, they significantly minimized hazardous waste, showcasing how deliberate strategies can lead to both environmental and financial benefits [1].

Looking beyond individual success stories, certain patterns emerge. Successful eco-industrial parks tend to align financial incentives with waste reduction efforts [1]. They often rely on anchor tenants that provide steady energy or material flows [12], and they emphasize improving operational performance rather than simply trading waste materials [2]. Resource Management contracts play a crucial role here by shifting contractor profits away from waste volume, motivating them to recover materials rather than defaulting to landfill disposal [1]. Interestingly, achieving these results doesn’t always require significant upfront investments. For example, Hypertherm empowered employees through "Green Champions" at the workstation level, combining lean manufacturing principles with sustainability goals. This approach not only reduced waste but also tied environmental efforts to profit-sharing opportunities through their ESOP structure [1].

In North America, regions with strong manufacturing bases, tech hubs, agricultural zones, and coastal ports offer unique opportunities for industrial symbiosis. For instance, thermal energy-sharing in the Great Lakes region or bio-industrial collaborations in farming areas demonstrate how local industrial profiles can align with targeted waste exchange strategies [1]. These examples highlight the broader theme of turning waste challenges into economic opportunities. However, achieving effective symbiosis depends on managing material and energy flows across regions [13].

For organizations looking to explore eco-industrial opportunities, the first step is mapping existing waste streams and identifying potential local partners. Structuring agreements that prioritize efficiency over disposal volume can further ensure success. Case studies across North America confirm that industrial symbiosis thrives when economic and environmental goals work hand in hand.

FAQs

What are the key benefits of industrial symbiosis for businesses and communities?

Industrial symbiosis brings businesses together by facilitating the exchange of materials, energy, water, and by-products, turning what would typically be waste into useful resources. For instance, companies can share waste heat or surplus electricity, helping to cut expenses, reduce carbon emissions, and boost overall efficiency. This collaborative approach also delivers environmental perks, such as cutting down on emissions, minimizing landfill use, and decreasing the need for raw materials.

From a financial perspective, businesses see benefits like reduced energy and material costs, along with opportunities to generate revenue by selling reclaimed by-products. On a broader scale, communities gain through job creation, economic development, and healthier living conditions, thanks to cleaner industrial practices and less pollution. These combined effects create a strong, sustainable framework that supports both local economies and environmental well-being.

How do government incentives help establish eco-industrial parks?

Government incentives are crucial in making eco-industrial parks a practical and appealing choice for businesses. By providing tax credits and accelerated depreciation for renewable energy installations like solar panels or combined heat and power systems, governments help reduce the upfront expenses for companies. Grants and low-interest loans further support efforts by funding feasibility studies, pilot programs, and shared infrastructure, such as waste-heat recovery systems.

Other forms of assistance include property tax abatements, flexible zoning regulations, and expedited permitting processes, all of which help lower land acquisition costs and ease regulatory challenges. Some policies even incentivize companies to divert waste to nearby facilities, transforming what would typically be a disposal expense into a potential source of income. These combined measures encourage collaboration, cut costs, and boost job opportunities, positioning eco-industrial parks as valuable components of broader regional economic plans.

What obstacles do eco-industrial parks face when turning waste into valuable byproducts?

Eco-industrial parks often encounter a range of obstacles when trying to transform waste streams into useful byproducts. One of the primary issues is the lack of adequate technology and infrastructure. Many facilities simply don’t have the equipment or logistical systems needed to efficiently process or transport materials. Moreover, poor collaboration between companies can slow progress, as businesses are often reluctant to share data or invest in joint initiatives without clear agreements on how costs and risks will be managed. Other hurdles include complex regulations, limited financial resources, and information gaps, where companies may not even realize that complementary byproducts exist nearby.

Another significant challenge stems from the design of these parks. Early attempts often relied on rigid exchange networks, which didn’t align with the organic, self-organizing patterns observed in successful cases like Kalundborg. Studies suggest that identifying and building on existing synergies - rather than imposing forced connections - leads to better, more sustainable outcomes. To achieve this, eco-industrial parks need supportive policies, tools, and platforms that encourage trust and collaboration among diverse participants.

Council Fire, a consultancy focused on sustainability, works with organizations to tackle these issues. By providing strategic advice on technology, partnerships, and policy approaches, they help eco-industrial parks across the U.S. create effective byproduct exchanges with measurable results.

Related Blog Posts

Latest Articles

©2025

FAQ

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Dec 22, 2025

Industrial Symbiosis in North America: Case Studies

Sustainability Strategy

In This Article

Two North American case studies on industrial symbiosis: water reuse, byproduct exchanges, shared infrastructure and policies that cut costs, emissions, and create revenue.

Industrial Symbiosis in North America: Case Studies

Industrial symbiosis turns waste into resources, creating value for businesses and communities. This article examines two North American examples: the Brownsville/Matamoros Eco-Industrial Park and the Sarnia-Lambton Industrial Partnership Network. Both showcase how collaboration among industries can reduce waste, conserve resources, and generate economic benefits.

Key Insights:

Brownsville/Matamoros Eco-Industrial Park: Focuses on water reuse and byproduct exchange. Initiatives like cascading water systems and sulfur recovery have cut costs and reduced waste.

Sarnia-Lambton Industrial Partnership Network: Located in Ontario’s “Chemical Valley,” it leverages its geographic and research advantages to integrate bio-industrial innovation and renewable energy projects.

These efforts highlight how industries can align resource use with financial and operational goals, supported by government incentives and shared infrastructure. The results include reduced emissions, lower costs, and new revenue streams, proving that industrial symbiosis benefits businesses and the environment alike.

Brownsville-Matamoros vs Sarnia-Lambton Industrial Symbiosis Comparison

Inside the world of industrial symbiosis | The origins of the circular economy

Case Study 1: Brownsville/Matamoros Eco-Industrial Park

The Brownsville/Matamoros Eco-Industrial Park represents a unique cross-border initiative between Brownsville, Texas, and Matamoros, Mexico. Recognized as a pilot project by the President's Council on Sustainable Development, this effort brought together the City of Brownsville, the Port of Brownsville, and the Brownsville Economic Development Council (BEDC). Their shared goal was to explore how industrial byproducts could be repurposed as resources instead of being treated as waste [4].

Park Design and Operations

A key focus of the park’s design is water conservation and reuse, achieved through a cascading water model. Local industries, which consume water on a scale comparable to municipal levels, benefit significantly from this approach [4]. In January 1995, the Brownsville Public Utilities Board introduced a system where high-quality effluent from semiconductor plants is reused as cooling water for other industrial facilities. This initiative has reduced the need for freshwater extraction [4][5].

The park also implemented several byproduct exchange programs. For instance, the Brownsville Refinery Corporation successfully recovered sulfur from flue gases and marketed gypsum derived from flue gas desulfurization to companies such as U.S. Gypsum. These efforts turned potential pollutants into valuable industrial inputs. Additionally, Geographic Information Systems (GIS) were used to combine water usage data with geographic information, helping identify new opportunities for byproduct exchanges [4][5].

These strategies have led to measurable economic and environmental improvements, as outlined below.

Measured Economic and Environmental Results

The economic advantages of water reuse are evident in the reduced costs associated with wastewater treatment. The cascading water model not only minimized the extraction of freshwater but also decreased the volume of wastewater requiring disposal [4][5]. Similarly, sulfur recovery and gypsum marketing efforts prevented harmful atmospheric emissions while creating revenue from materials that would otherwise be discarded [5]. Other initiatives, such as repurposing fly ash from power plants for construction and recycling solvents to cut down on hazardous waste, further underscore the project's impact.

However, despite these achievements, regulatory hurdles have posed challenges. Strict waste classifications and complex permitting requirements have slowed the implementation of some planned byproduct exchanges in the region [5]. The groundwork for these efforts was laid in a 1994 feasibility study conducted by Indigo Development in partnership with the U.S. EPA, which set the stage for these innovative collaborations [4].

Case Study 2: Sarnia-Lambton Industrial Partnership Network

The Sarnia-Lambton region in Ontario, Canada, often referred to as Canada's Chemical Valley, stands out as a prime example of industrial symbiosis in action. With its chemical industry generating over $4 billion in annual revenue and contributing more than $12 million in municipal taxes each year, this area, home to about 72,000 residents, has become a North American leader in industrial ecology [8]. This case highlights how diverse approaches to industrial symbiosis can thrive in North America.

Key Factors Behind Sarnia-Lambton's Success

The region's achievements are rooted in a combination of strategic advantages. Its location is a significant factor - within a one-day trucking distance of 54% of the U.S. payroll and 65% of Canadian GDP, as well as proximity to 60% of North America's plastic resin markets. This geographic positioning fosters competitive collaboration [8]. John Margeson, Senior Industry Officer at Industry Canada, summed it up well:

"Petrochemical companies normally like to be part of an industry cluster because this allows product and by‐product streams to be exchanged between sites, improving overall competitiveness. One company's by‐product can become another's feedstock" [8].

The region also benefits from robust technical and research infrastructure. The Western Sarnia-Lambton Research Park and Bioindustrial Innovation Canada serve as bridges between traditional petrochemical industries and emerging sectors like biochemical and clean energy [6]. An important milestone came in 2003, when Lambton's Community Development Corporation acquired a 200,000-square-foot former Dow Chemical facility for $8 million. An additional $12 million investment transformed it into the University of Western Ontario Sarnia-Lambton Research Park, which now oversees 150 research projects, 90 of which focus on bio-industrial innovation [8]. The region's workforce is supported by Lambton College, which ensures a steady supply of skilled professionals [8]. Together, these resources have established Sarnia-Lambton as a hub for ongoing advancements in industrial symbiosis.

Outcomes from the Bruce Energy Centre

The Bruce Energy Centre demonstrates how these factors translate into tangible results. The region's industrial symbiosis is evident in initiatives like steam cascading and the marketing of by-product gypsum [7]. Suncor Energy's ethanol plant, once the largest in Canada, has reduced CO2 emissions by 300,000 tonnes annually [8]. Additionally, the area has attracted significant renewable energy projects, such as OptiSolar's 60-megawatt solar farm and Greenfield Energy's 1,005-megawatt power generation facility, both aimed at cutting greenhouse gas emissions [8]. In February 2008, federal and provincial governments each contributed $15 million to launch a bio-industrial innovation center, a project expected to create 1,000 jobs [8].

Design Principles for Eco-Industrial Parks

Eco-industrial parks thrive on strategies that turn waste into valuable resources, creating a cycle of efficiency and sustainability. A foundational approach is resource mapping, which involves tracking flows of energy, water, and materials in real time. This process uncovers opportunities for companies to exchange resources, reducing waste and improving efficiency. As Jonathan S. Krones from Yale University explains:

"The practice of turning byproducts into the valuable inputs of another industry is as ancient as economic development itself" [1].

Another key to success is shared infrastructure, where participants jointly invest in systems like renewable energy sources, water treatment facilities, and district heating networks. This collaborative approach not only lowers costs but also minimizes environmental impact. Contracts within these parks often:

"decouple the quantity of waste disposed from the contractor's profit by providing financial incentives for services related to material consumption, use and recovery" [1].

The development style of eco-industrial parks also matters. For instance, Denmark's Kalundborg network evolved organically over time without a rigid master plan, while some U.S. parks, designed with strict guidelines, have faced challenges [9]. Successful models in North America strike a balance between structured planning and the flexibility to allow organic relationships to develop naturally. These principles form the backbone of the design process detailed below.

Steps for Designing Eco-Industrial Parks

The first step in designing an eco-industrial park is resource mapping, leveraging tools like sensors and data analytics to identify inefficiencies and potential symbiotic exchanges. This step uncovers opportunities that isolated operations might overlook.

Next, stakeholder alignment is crucial. Building networks with local governments and utilities can provide regulatory support and incentives, ensuring all parties work toward shared goals.

Designing shared infrastructure comes next. This includes systems for renewable energy, waste-to-energy conversion, and water treatment. To ensure long-term success, governance structures - such as collaborative management and joint ownership models - should be established to distribute benefits fairly and maintain stability.

Finally, performance must be monitored continuously. Using economic, environmental, and social indicators, parks can track progress and demonstrate returns on investment, keeping stakeholders engaged and committed.

Measuring Performance in Eco-Industrial Parks

Performance evaluation in eco-industrial parks typically focuses on three main indicators:

Economic: Metrics like cost savings, revenue from by-product sales, and job creation.

Environmental: Indicators such as waste reduction, emissions cuts, and resource conservation.

Social: Measures including community health improvements, workforce development, and local economic benefits.

Quantitative tools like Material Flow Analysis, Life Cycle Assessment, and Environmentally Extended Input-Output Analysis are often employed to assess these outcomes [3].

Real-world examples show that systematic performance measurement not only enhances resource efficiency but also boosts economic returns, proving the value of these collaborative ecosystems.

Government Support for Industrial Symbiosis

Government policies and incentives play a key role in advancing industrial symbiosis, turning eco-industrial parks into thriving operational centers. Without such support, companies often find it difficult to justify the initial costs associated with symbiotic practices. These efforts complement the strategic designs and operational advancements that underpin successful industrial ecosystems.

Policy and Regulatory Frameworks

State and federal policies serve as a backbone for industrial symbiosis, offering both guidance and financial incentives. For instance, Washington's SB 5345, enacted in May 2021, and federal programs like the President's Council on Sustainable Development (PCSD) provide essential support. Washington State's legislation, managed by the Department of Commerce, offers practical guidance and proven strategies for industrial symbiosis. It also includes a grant program aimed at bolstering local waste coordination efforts [10].

Tax incentives further enhance these initiatives. Across North America, local governments now provide tax breaks to companies that successfully divert waste through symbiotic collaborations [10].

At the federal level, the President's Council on Sustainable Development (PCSD), established on June 29, 1993, legitimized eco-industrial development in the U.S. by fostering cooperation among industries, governments, and environmental organizations [11].

Infrastructure Funding and Incentives

Government investment in infrastructure development has proven to deliver tangible outcomes. For example, Environment Canada supported the creation of the Burnside Eco-Industrial Park in Nova Scotia, showcasing a pilot industrial ecosystem [11]. Similarly, the Town of Cape Charles and Northampton County, Virginia, co-sponsored the Port of Cape Charles Sustainable Technologies Industrial Park [11].

These examples highlight that government involvement extends beyond financial support, encompassing planning, technical expertise, and a long-term commitment to fostering sustainable industrial practices.

Council Fire's Work in Industrial Symbiosis

Council Fire takes industrial symbiosis from concept to action by combining government incentives and thoughtful design with tangible results. Their systems-thinking approach helps organizations transition from sustainability planning to actionable strategies. Collaborating with companies, governments, and nonprofits across North America, they design and implement eco-industrial parks that deliver both environmental improvements and economic gains.

Their process integrates energy mapping with detailed financial modeling to ensure every symbiotic exchange makes economic sense. By conducting in-depth technical and financial analyses, Council Fire evaluates energy-sharing opportunities, projects return on investment (ROI), and develops scalable energy systems suited to specific industrial needs. This approach enables effective resource recovery, laying the groundwork for eco-industrial success. For instance, their work on the Sarnia-Lambton Eco-Industrial Park focuses on refining renewable energy integration and resource management to significantly reduce carbon emissions.

What sets Council Fire apart is their hands-on involvement in project execution. Rather than simply producing compliance reports, they turn sustainability goals into actionable steps using data-driven insights and by aligning stakeholders. From initial feasibility studies to performance measurement, their efforts include developing communication strategies that build trust and encourage collaboration among all parties involved.

Their work underscores that industrial symbiosis is about more than technical know-how. It requires strategic coordination, robust financial planning, and the ability to turn ambitious environmental objectives into practical, operational outcomes that deliver lasting benefits for everyone involved.

Key Takeaways

Industrial symbiosis delivers tangible results. Take the Casella-Hypertherm partnership as an example: between 2010 and 2014, they managed to cut disposed waste by nearly half, dropping from 191 to 98 metric tons. They also reduced their disposal rate from 14% to just 4.4%. By focusing on targeted interventions, they significantly minimized hazardous waste, showcasing how deliberate strategies can lead to both environmental and financial benefits [1].

Looking beyond individual success stories, certain patterns emerge. Successful eco-industrial parks tend to align financial incentives with waste reduction efforts [1]. They often rely on anchor tenants that provide steady energy or material flows [12], and they emphasize improving operational performance rather than simply trading waste materials [2]. Resource Management contracts play a crucial role here by shifting contractor profits away from waste volume, motivating them to recover materials rather than defaulting to landfill disposal [1]. Interestingly, achieving these results doesn’t always require significant upfront investments. For example, Hypertherm empowered employees through "Green Champions" at the workstation level, combining lean manufacturing principles with sustainability goals. This approach not only reduced waste but also tied environmental efforts to profit-sharing opportunities through their ESOP structure [1].

In North America, regions with strong manufacturing bases, tech hubs, agricultural zones, and coastal ports offer unique opportunities for industrial symbiosis. For instance, thermal energy-sharing in the Great Lakes region or bio-industrial collaborations in farming areas demonstrate how local industrial profiles can align with targeted waste exchange strategies [1]. These examples highlight the broader theme of turning waste challenges into economic opportunities. However, achieving effective symbiosis depends on managing material and energy flows across regions [13].

For organizations looking to explore eco-industrial opportunities, the first step is mapping existing waste streams and identifying potential local partners. Structuring agreements that prioritize efficiency over disposal volume can further ensure success. Case studies across North America confirm that industrial symbiosis thrives when economic and environmental goals work hand in hand.

FAQs

What are the key benefits of industrial symbiosis for businesses and communities?

Industrial symbiosis brings businesses together by facilitating the exchange of materials, energy, water, and by-products, turning what would typically be waste into useful resources. For instance, companies can share waste heat or surplus electricity, helping to cut expenses, reduce carbon emissions, and boost overall efficiency. This collaborative approach also delivers environmental perks, such as cutting down on emissions, minimizing landfill use, and decreasing the need for raw materials.

From a financial perspective, businesses see benefits like reduced energy and material costs, along with opportunities to generate revenue by selling reclaimed by-products. On a broader scale, communities gain through job creation, economic development, and healthier living conditions, thanks to cleaner industrial practices and less pollution. These combined effects create a strong, sustainable framework that supports both local economies and environmental well-being.

How do government incentives help establish eco-industrial parks?

Government incentives are crucial in making eco-industrial parks a practical and appealing choice for businesses. By providing tax credits and accelerated depreciation for renewable energy installations like solar panels or combined heat and power systems, governments help reduce the upfront expenses for companies. Grants and low-interest loans further support efforts by funding feasibility studies, pilot programs, and shared infrastructure, such as waste-heat recovery systems.

Other forms of assistance include property tax abatements, flexible zoning regulations, and expedited permitting processes, all of which help lower land acquisition costs and ease regulatory challenges. Some policies even incentivize companies to divert waste to nearby facilities, transforming what would typically be a disposal expense into a potential source of income. These combined measures encourage collaboration, cut costs, and boost job opportunities, positioning eco-industrial parks as valuable components of broader regional economic plans.

What obstacles do eco-industrial parks face when turning waste into valuable byproducts?

Eco-industrial parks often encounter a range of obstacles when trying to transform waste streams into useful byproducts. One of the primary issues is the lack of adequate technology and infrastructure. Many facilities simply don’t have the equipment or logistical systems needed to efficiently process or transport materials. Moreover, poor collaboration between companies can slow progress, as businesses are often reluctant to share data or invest in joint initiatives without clear agreements on how costs and risks will be managed. Other hurdles include complex regulations, limited financial resources, and information gaps, where companies may not even realize that complementary byproducts exist nearby.

Another significant challenge stems from the design of these parks. Early attempts often relied on rigid exchange networks, which didn’t align with the organic, self-organizing patterns observed in successful cases like Kalundborg. Studies suggest that identifying and building on existing synergies - rather than imposing forced connections - leads to better, more sustainable outcomes. To achieve this, eco-industrial parks need supportive policies, tools, and platforms that encourage trust and collaboration among diverse participants.

Council Fire, a consultancy focused on sustainability, works with organizations to tackle these issues. By providing strategic advice on technology, partnerships, and policy approaches, they help eco-industrial parks across the U.S. create effective byproduct exchanges with measurable results.

Related Blog Posts

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Dec 22, 2025

Industrial Symbiosis in North America: Case Studies

Sustainability Strategy

In This Article

Two North American case studies on industrial symbiosis: water reuse, byproduct exchanges, shared infrastructure and policies that cut costs, emissions, and create revenue.

Industrial Symbiosis in North America: Case Studies

Industrial symbiosis turns waste into resources, creating value for businesses and communities. This article examines two North American examples: the Brownsville/Matamoros Eco-Industrial Park and the Sarnia-Lambton Industrial Partnership Network. Both showcase how collaboration among industries can reduce waste, conserve resources, and generate economic benefits.

Key Insights:

Brownsville/Matamoros Eco-Industrial Park: Focuses on water reuse and byproduct exchange. Initiatives like cascading water systems and sulfur recovery have cut costs and reduced waste.

Sarnia-Lambton Industrial Partnership Network: Located in Ontario’s “Chemical Valley,” it leverages its geographic and research advantages to integrate bio-industrial innovation and renewable energy projects.

These efforts highlight how industries can align resource use with financial and operational goals, supported by government incentives and shared infrastructure. The results include reduced emissions, lower costs, and new revenue streams, proving that industrial symbiosis benefits businesses and the environment alike.

Brownsville-Matamoros vs Sarnia-Lambton Industrial Symbiosis Comparison

Inside the world of industrial symbiosis | The origins of the circular economy

Case Study 1: Brownsville/Matamoros Eco-Industrial Park

The Brownsville/Matamoros Eco-Industrial Park represents a unique cross-border initiative between Brownsville, Texas, and Matamoros, Mexico. Recognized as a pilot project by the President's Council on Sustainable Development, this effort brought together the City of Brownsville, the Port of Brownsville, and the Brownsville Economic Development Council (BEDC). Their shared goal was to explore how industrial byproducts could be repurposed as resources instead of being treated as waste [4].

Park Design and Operations

A key focus of the park’s design is water conservation and reuse, achieved through a cascading water model. Local industries, which consume water on a scale comparable to municipal levels, benefit significantly from this approach [4]. In January 1995, the Brownsville Public Utilities Board introduced a system where high-quality effluent from semiconductor plants is reused as cooling water for other industrial facilities. This initiative has reduced the need for freshwater extraction [4][5].

The park also implemented several byproduct exchange programs. For instance, the Brownsville Refinery Corporation successfully recovered sulfur from flue gases and marketed gypsum derived from flue gas desulfurization to companies such as U.S. Gypsum. These efforts turned potential pollutants into valuable industrial inputs. Additionally, Geographic Information Systems (GIS) were used to combine water usage data with geographic information, helping identify new opportunities for byproduct exchanges [4][5].

These strategies have led to measurable economic and environmental improvements, as outlined below.

Measured Economic and Environmental Results

The economic advantages of water reuse are evident in the reduced costs associated with wastewater treatment. The cascading water model not only minimized the extraction of freshwater but also decreased the volume of wastewater requiring disposal [4][5]. Similarly, sulfur recovery and gypsum marketing efforts prevented harmful atmospheric emissions while creating revenue from materials that would otherwise be discarded [5]. Other initiatives, such as repurposing fly ash from power plants for construction and recycling solvents to cut down on hazardous waste, further underscore the project's impact.

However, despite these achievements, regulatory hurdles have posed challenges. Strict waste classifications and complex permitting requirements have slowed the implementation of some planned byproduct exchanges in the region [5]. The groundwork for these efforts was laid in a 1994 feasibility study conducted by Indigo Development in partnership with the U.S. EPA, which set the stage for these innovative collaborations [4].

Case Study 2: Sarnia-Lambton Industrial Partnership Network

The Sarnia-Lambton region in Ontario, Canada, often referred to as Canada's Chemical Valley, stands out as a prime example of industrial symbiosis in action. With its chemical industry generating over $4 billion in annual revenue and contributing more than $12 million in municipal taxes each year, this area, home to about 72,000 residents, has become a North American leader in industrial ecology [8]. This case highlights how diverse approaches to industrial symbiosis can thrive in North America.

Key Factors Behind Sarnia-Lambton's Success

The region's achievements are rooted in a combination of strategic advantages. Its location is a significant factor - within a one-day trucking distance of 54% of the U.S. payroll and 65% of Canadian GDP, as well as proximity to 60% of North America's plastic resin markets. This geographic positioning fosters competitive collaboration [8]. John Margeson, Senior Industry Officer at Industry Canada, summed it up well:

"Petrochemical companies normally like to be part of an industry cluster because this allows product and by‐product streams to be exchanged between sites, improving overall competitiveness. One company's by‐product can become another's feedstock" [8].

The region also benefits from robust technical and research infrastructure. The Western Sarnia-Lambton Research Park and Bioindustrial Innovation Canada serve as bridges between traditional petrochemical industries and emerging sectors like biochemical and clean energy [6]. An important milestone came in 2003, when Lambton's Community Development Corporation acquired a 200,000-square-foot former Dow Chemical facility for $8 million. An additional $12 million investment transformed it into the University of Western Ontario Sarnia-Lambton Research Park, which now oversees 150 research projects, 90 of which focus on bio-industrial innovation [8]. The region's workforce is supported by Lambton College, which ensures a steady supply of skilled professionals [8]. Together, these resources have established Sarnia-Lambton as a hub for ongoing advancements in industrial symbiosis.

Outcomes from the Bruce Energy Centre

The Bruce Energy Centre demonstrates how these factors translate into tangible results. The region's industrial symbiosis is evident in initiatives like steam cascading and the marketing of by-product gypsum [7]. Suncor Energy's ethanol plant, once the largest in Canada, has reduced CO2 emissions by 300,000 tonnes annually [8]. Additionally, the area has attracted significant renewable energy projects, such as OptiSolar's 60-megawatt solar farm and Greenfield Energy's 1,005-megawatt power generation facility, both aimed at cutting greenhouse gas emissions [8]. In February 2008, federal and provincial governments each contributed $15 million to launch a bio-industrial innovation center, a project expected to create 1,000 jobs [8].

Design Principles for Eco-Industrial Parks

Eco-industrial parks thrive on strategies that turn waste into valuable resources, creating a cycle of efficiency and sustainability. A foundational approach is resource mapping, which involves tracking flows of energy, water, and materials in real time. This process uncovers opportunities for companies to exchange resources, reducing waste and improving efficiency. As Jonathan S. Krones from Yale University explains:

"The practice of turning byproducts into the valuable inputs of another industry is as ancient as economic development itself" [1].

Another key to success is shared infrastructure, where participants jointly invest in systems like renewable energy sources, water treatment facilities, and district heating networks. This collaborative approach not only lowers costs but also minimizes environmental impact. Contracts within these parks often:

"decouple the quantity of waste disposed from the contractor's profit by providing financial incentives for services related to material consumption, use and recovery" [1].

The development style of eco-industrial parks also matters. For instance, Denmark's Kalundborg network evolved organically over time without a rigid master plan, while some U.S. parks, designed with strict guidelines, have faced challenges [9]. Successful models in North America strike a balance between structured planning and the flexibility to allow organic relationships to develop naturally. These principles form the backbone of the design process detailed below.

Steps for Designing Eco-Industrial Parks

The first step in designing an eco-industrial park is resource mapping, leveraging tools like sensors and data analytics to identify inefficiencies and potential symbiotic exchanges. This step uncovers opportunities that isolated operations might overlook.

Next, stakeholder alignment is crucial. Building networks with local governments and utilities can provide regulatory support and incentives, ensuring all parties work toward shared goals.

Designing shared infrastructure comes next. This includes systems for renewable energy, waste-to-energy conversion, and water treatment. To ensure long-term success, governance structures - such as collaborative management and joint ownership models - should be established to distribute benefits fairly and maintain stability.

Finally, performance must be monitored continuously. Using economic, environmental, and social indicators, parks can track progress and demonstrate returns on investment, keeping stakeholders engaged and committed.

Measuring Performance in Eco-Industrial Parks

Performance evaluation in eco-industrial parks typically focuses on three main indicators:

Economic: Metrics like cost savings, revenue from by-product sales, and job creation.

Environmental: Indicators such as waste reduction, emissions cuts, and resource conservation.

Social: Measures including community health improvements, workforce development, and local economic benefits.

Quantitative tools like Material Flow Analysis, Life Cycle Assessment, and Environmentally Extended Input-Output Analysis are often employed to assess these outcomes [3].

Real-world examples show that systematic performance measurement not only enhances resource efficiency but also boosts economic returns, proving the value of these collaborative ecosystems.

Government Support for Industrial Symbiosis

Government policies and incentives play a key role in advancing industrial symbiosis, turning eco-industrial parks into thriving operational centers. Without such support, companies often find it difficult to justify the initial costs associated with symbiotic practices. These efforts complement the strategic designs and operational advancements that underpin successful industrial ecosystems.

Policy and Regulatory Frameworks

State and federal policies serve as a backbone for industrial symbiosis, offering both guidance and financial incentives. For instance, Washington's SB 5345, enacted in May 2021, and federal programs like the President's Council on Sustainable Development (PCSD) provide essential support. Washington State's legislation, managed by the Department of Commerce, offers practical guidance and proven strategies for industrial symbiosis. It also includes a grant program aimed at bolstering local waste coordination efforts [10].

Tax incentives further enhance these initiatives. Across North America, local governments now provide tax breaks to companies that successfully divert waste through symbiotic collaborations [10].

At the federal level, the President's Council on Sustainable Development (PCSD), established on June 29, 1993, legitimized eco-industrial development in the U.S. by fostering cooperation among industries, governments, and environmental organizations [11].

Infrastructure Funding and Incentives

Government investment in infrastructure development has proven to deliver tangible outcomes. For example, Environment Canada supported the creation of the Burnside Eco-Industrial Park in Nova Scotia, showcasing a pilot industrial ecosystem [11]. Similarly, the Town of Cape Charles and Northampton County, Virginia, co-sponsored the Port of Cape Charles Sustainable Technologies Industrial Park [11].

These examples highlight that government involvement extends beyond financial support, encompassing planning, technical expertise, and a long-term commitment to fostering sustainable industrial practices.

Council Fire's Work in Industrial Symbiosis

Council Fire takes industrial symbiosis from concept to action by combining government incentives and thoughtful design with tangible results. Their systems-thinking approach helps organizations transition from sustainability planning to actionable strategies. Collaborating with companies, governments, and nonprofits across North America, they design and implement eco-industrial parks that deliver both environmental improvements and economic gains.

Their process integrates energy mapping with detailed financial modeling to ensure every symbiotic exchange makes economic sense. By conducting in-depth technical and financial analyses, Council Fire evaluates energy-sharing opportunities, projects return on investment (ROI), and develops scalable energy systems suited to specific industrial needs. This approach enables effective resource recovery, laying the groundwork for eco-industrial success. For instance, their work on the Sarnia-Lambton Eco-Industrial Park focuses on refining renewable energy integration and resource management to significantly reduce carbon emissions.

What sets Council Fire apart is their hands-on involvement in project execution. Rather than simply producing compliance reports, they turn sustainability goals into actionable steps using data-driven insights and by aligning stakeholders. From initial feasibility studies to performance measurement, their efforts include developing communication strategies that build trust and encourage collaboration among all parties involved.

Their work underscores that industrial symbiosis is about more than technical know-how. It requires strategic coordination, robust financial planning, and the ability to turn ambitious environmental objectives into practical, operational outcomes that deliver lasting benefits for everyone involved.

Key Takeaways

Industrial symbiosis delivers tangible results. Take the Casella-Hypertherm partnership as an example: between 2010 and 2014, they managed to cut disposed waste by nearly half, dropping from 191 to 98 metric tons. They also reduced their disposal rate from 14% to just 4.4%. By focusing on targeted interventions, they significantly minimized hazardous waste, showcasing how deliberate strategies can lead to both environmental and financial benefits [1].

Looking beyond individual success stories, certain patterns emerge. Successful eco-industrial parks tend to align financial incentives with waste reduction efforts [1]. They often rely on anchor tenants that provide steady energy or material flows [12], and they emphasize improving operational performance rather than simply trading waste materials [2]. Resource Management contracts play a crucial role here by shifting contractor profits away from waste volume, motivating them to recover materials rather than defaulting to landfill disposal [1]. Interestingly, achieving these results doesn’t always require significant upfront investments. For example, Hypertherm empowered employees through "Green Champions" at the workstation level, combining lean manufacturing principles with sustainability goals. This approach not only reduced waste but also tied environmental efforts to profit-sharing opportunities through their ESOP structure [1].

In North America, regions with strong manufacturing bases, tech hubs, agricultural zones, and coastal ports offer unique opportunities for industrial symbiosis. For instance, thermal energy-sharing in the Great Lakes region or bio-industrial collaborations in farming areas demonstrate how local industrial profiles can align with targeted waste exchange strategies [1]. These examples highlight the broader theme of turning waste challenges into economic opportunities. However, achieving effective symbiosis depends on managing material and energy flows across regions [13].

For organizations looking to explore eco-industrial opportunities, the first step is mapping existing waste streams and identifying potential local partners. Structuring agreements that prioritize efficiency over disposal volume can further ensure success. Case studies across North America confirm that industrial symbiosis thrives when economic and environmental goals work hand in hand.

FAQs

What are the key benefits of industrial symbiosis for businesses and communities?

Industrial symbiosis brings businesses together by facilitating the exchange of materials, energy, water, and by-products, turning what would typically be waste into useful resources. For instance, companies can share waste heat or surplus electricity, helping to cut expenses, reduce carbon emissions, and boost overall efficiency. This collaborative approach also delivers environmental perks, such as cutting down on emissions, minimizing landfill use, and decreasing the need for raw materials.

From a financial perspective, businesses see benefits like reduced energy and material costs, along with opportunities to generate revenue by selling reclaimed by-products. On a broader scale, communities gain through job creation, economic development, and healthier living conditions, thanks to cleaner industrial practices and less pollution. These combined effects create a strong, sustainable framework that supports both local economies and environmental well-being.

How do government incentives help establish eco-industrial parks?

Government incentives are crucial in making eco-industrial parks a practical and appealing choice for businesses. By providing tax credits and accelerated depreciation for renewable energy installations like solar panels or combined heat and power systems, governments help reduce the upfront expenses for companies. Grants and low-interest loans further support efforts by funding feasibility studies, pilot programs, and shared infrastructure, such as waste-heat recovery systems.

Other forms of assistance include property tax abatements, flexible zoning regulations, and expedited permitting processes, all of which help lower land acquisition costs and ease regulatory challenges. Some policies even incentivize companies to divert waste to nearby facilities, transforming what would typically be a disposal expense into a potential source of income. These combined measures encourage collaboration, cut costs, and boost job opportunities, positioning eco-industrial parks as valuable components of broader regional economic plans.

What obstacles do eco-industrial parks face when turning waste into valuable byproducts?

Eco-industrial parks often encounter a range of obstacles when trying to transform waste streams into useful byproducts. One of the primary issues is the lack of adequate technology and infrastructure. Many facilities simply don’t have the equipment or logistical systems needed to efficiently process or transport materials. Moreover, poor collaboration between companies can slow progress, as businesses are often reluctant to share data or invest in joint initiatives without clear agreements on how costs and risks will be managed. Other hurdles include complex regulations, limited financial resources, and information gaps, where companies may not even realize that complementary byproducts exist nearby.

Another significant challenge stems from the design of these parks. Early attempts often relied on rigid exchange networks, which didn’t align with the organic, self-organizing patterns observed in successful cases like Kalundborg. Studies suggest that identifying and building on existing synergies - rather than imposing forced connections - leads to better, more sustainable outcomes. To achieve this, eco-industrial parks need supportive policies, tools, and platforms that encourage trust and collaboration among diverse participants.

Council Fire, a consultancy focused on sustainability, works with organizations to tackle these issues. By providing strategic advice on technology, partnerships, and policy approaches, they help eco-industrial parks across the U.S. create effective byproduct exchanges with measurable results.

Related Blog Posts

FAQ

What does it really mean to “redefine profit”?

What makes Council Fire different?

Who does Council Fire you work with?

What does working with Council Fire actually look like?

How does Council Fire help organizations turn big goals into action?

How does Council Fire define and measure success?