Jan 4, 2026

Jan 4, 2026

How to Ensure Transparency in Circular Supply Chains

Sustainability Strategy

Sustainability Strategy

In This Article

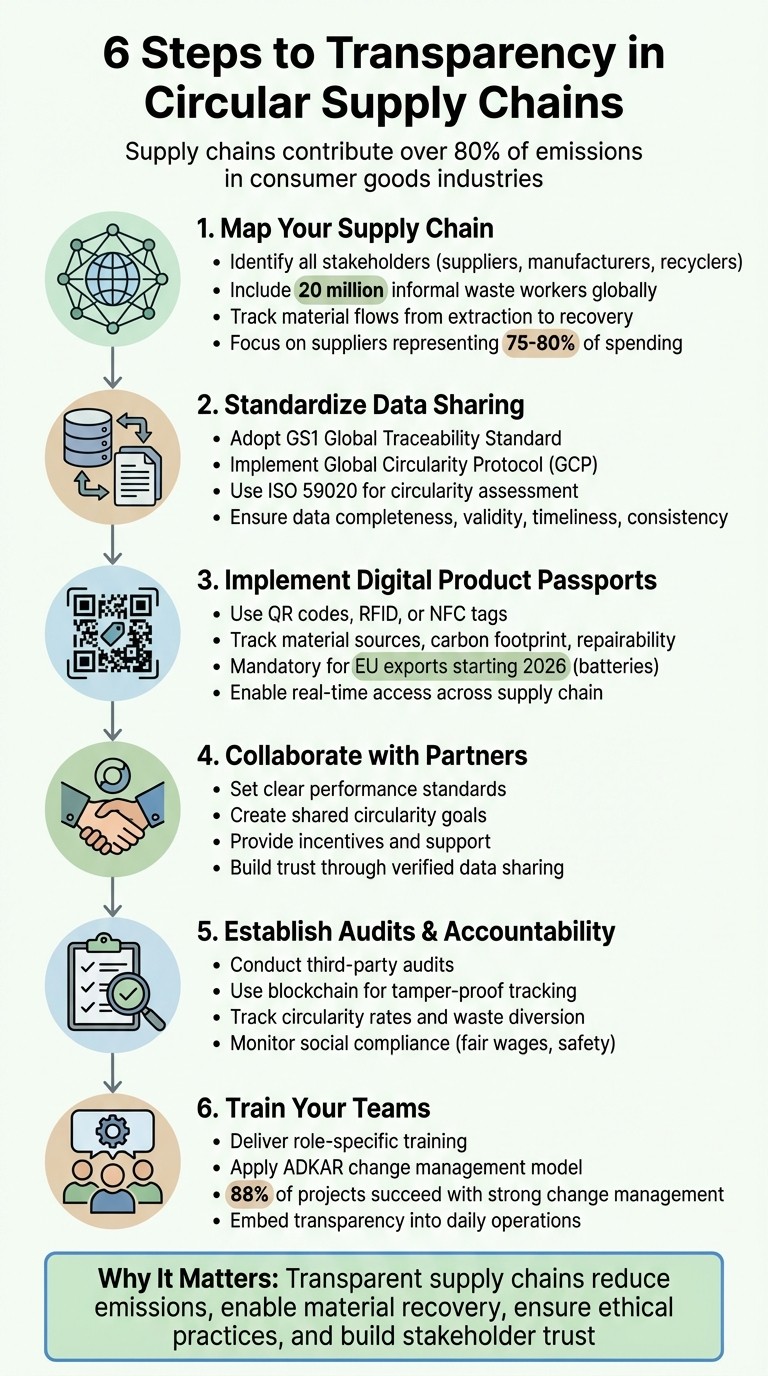

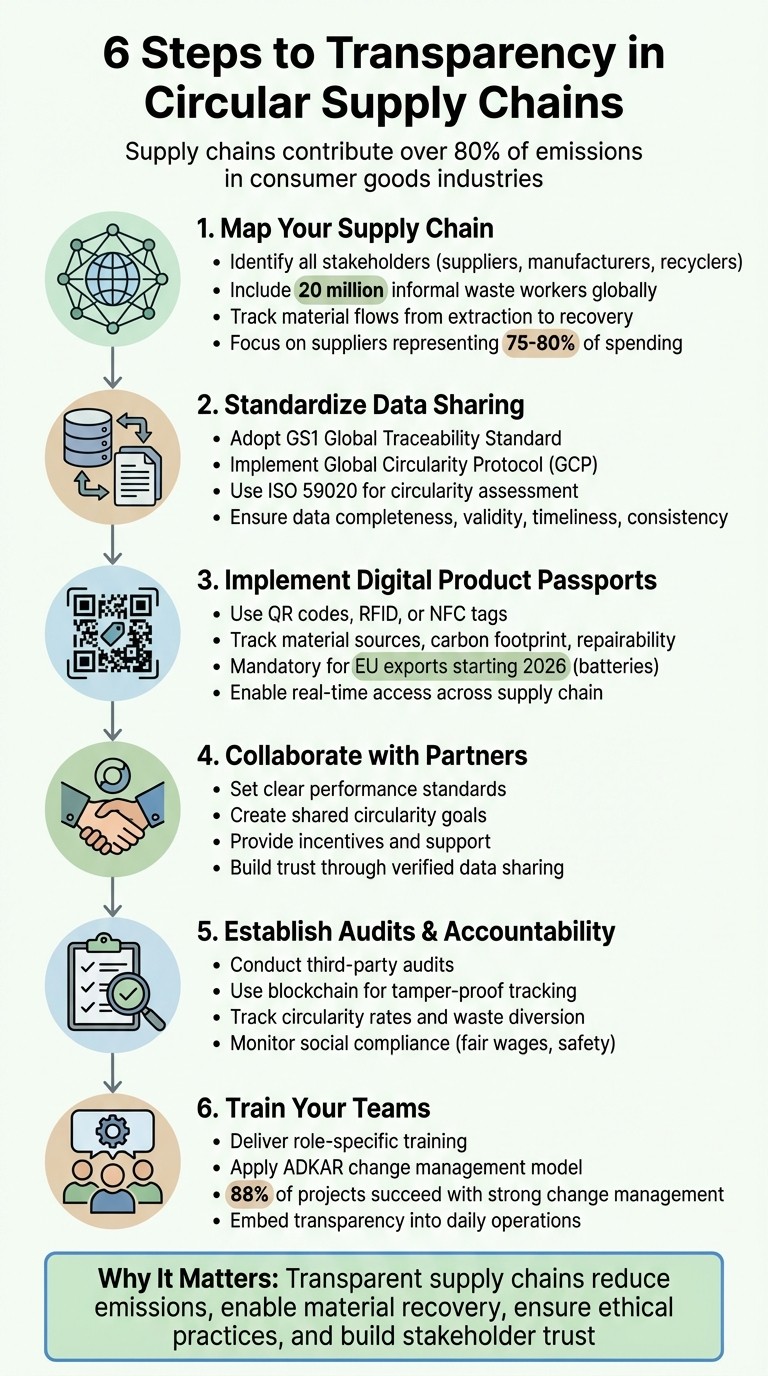

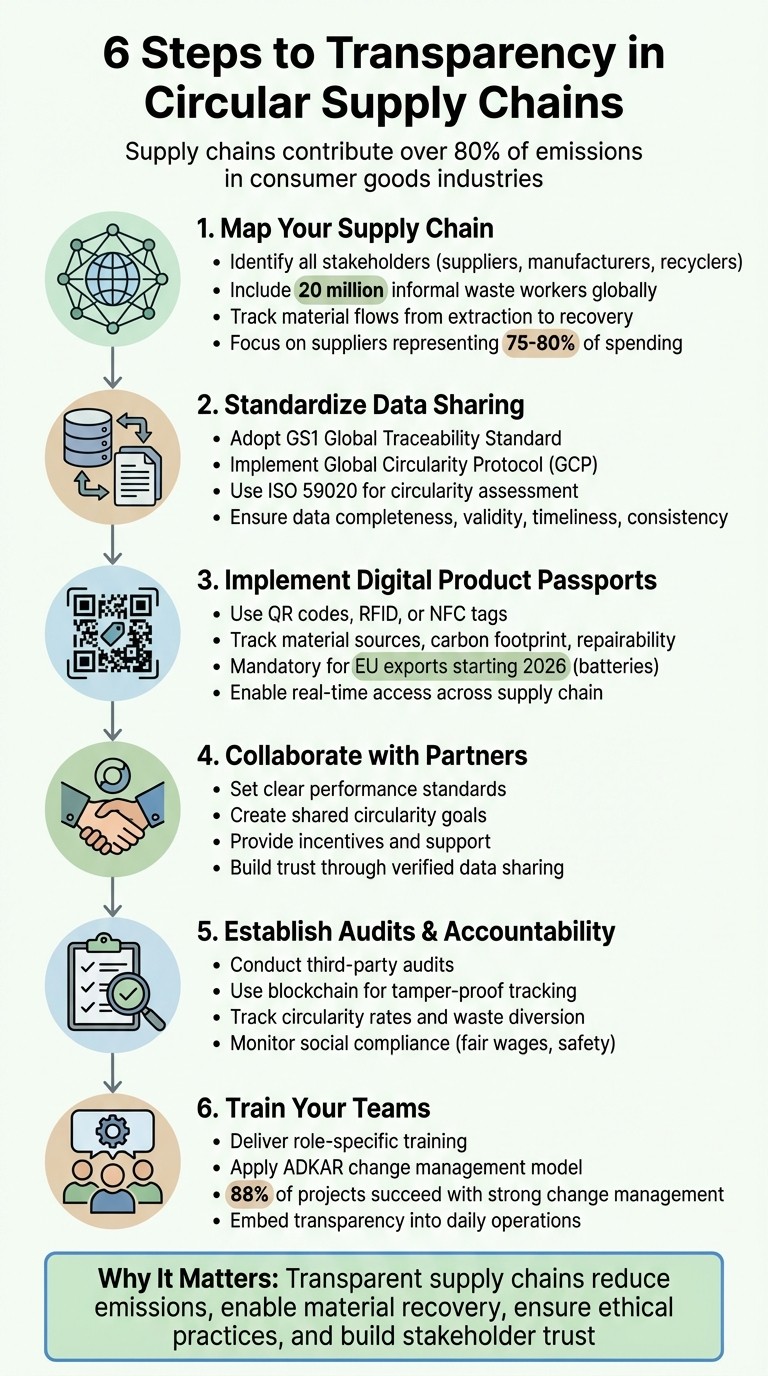

True circularity depends on end-to-end transparency: map flows, standardize data, use digital product passports, audit partners, and train teams.

How to Ensure Transparency in Circular Supply Chains

Transparency is the backbone of circular supply chains, enabling efficient material reuse, ethical practices, and reduced emissions. Here's how organizations can achieve it:

Map the Supply Chain: Identify all participants, including informal waste workers, and track material flows from extraction to recovery.

Standardize Data Sharing: Use global standards like GS1 or protocols such as the Global Circularity Protocol to ensure consistent and reliable data exchange.

Implement Digital Product Passports (DPPs): Equip products with QR codes or RFID tags to provide lifecycle details, aiding repair, recycling, and compliance with regulations like the EU's Ecodesign directive.

Collaborate with Partners: Build trust by setting clear expectations, offering incentives, and supporting smaller suppliers with training and resources.

Conduct Audits: Use third-party audits and tools like blockchain to verify data accuracy and track circularity metrics.

Train Teams: Equip employees with role-specific knowledge to manage transparency systems effectively, ensuring long-term success.

Why it matters: Supply chains contribute over 80% of emissions in consumer goods industries. Transparency not only supports material recovery and ethical practices but also helps businesses meet regulatory demands, reduce risks, and build trust with stakeholders.

6 Steps to Achieve Transparency in Circular Supply Chains

Using Digital Traceability to Drive Supply Chain Transparency

Step 1: Map Your Complete Supply Chain

To create a comprehensive view of your supply chain, document every participant and movement of materials, starting from raw material extraction and extending all the way to material recovery. Circular systems are complex, with multidirectional flows where customers can become suppliers and recyclers play a vital role in returning materials to the system [1][2]. Begin by breaking down the chain to identify key stakeholders and material flows.

Identify Stakeholders and Material Flows

Start by listing all key players in your supply chain, such as direct suppliers, manufacturers, distributors, repair services, and recyclers. Don’t forget the informal sector, which includes approximately 20 million informal waste workers worldwide. These workers are critical for collecting and processing materials, yet they are often left out of traditional supply chain maps [4]. Including them is essential for creating a truly circular system. Organizations can also [empower communities] (https://www.councilfire.org/future-leaders-program) by integrating these workers into formal structures.

Focus on identifying key suppliers, particularly those responsible for 75–80% of your spending or those linked to high brand risks. Record crucial details such as chemical compositions, sourcing origins, purchase orders, quality standards, and disassembly options. This information ensures better management and transparency throughout the supply chain [3][5].

Use Supply Chain Mapping Tools

Once you’ve outlined stakeholders and material flows, use specialized tools to visualize and analyze your supply chain. Platforms like Circularise, Provenance, Circulor, TraceX, and Reath can enhance traceability and provide a clearer picture of your value chain [3]. To measure circularity performance, explore frameworks like WBCSD's Circular Transition Indicators, the Ellen MacArthur Foundation's Circulytics, or BCG's CIRCelligence [3][7].

If informal waste pickers or recyclers are part of your supply chain, tools like BanQu and Plastic Bank are designed to map their activities and improve transparency. These platforms not only highlight their contributions but also ensure fair compensation, bringing visibility to the entire material recovery process [3]. By integrating these tools, you can create a more inclusive and transparent supply chain.

Step 2: Set Up Standardized Data Sharing Protocols

Once you've mapped your supply chain, the next step is to ensure all partners are speaking the same "data language." Without a standardized approach, critical details can get lost, creating bottlenecks in transparency. The key is to implement global data-sharing standards that provide a unified framework for documenting and exchanging information. This builds on your supply chain map, ensuring that data flows remain consistent and dependable.

Adopt Global Data Sharing Standards

A good starting point is the GS1 Global Traceability Standard [8][9]. This framework enables organizations to identify, capture, and share product information in a common language, making data exchange smoother across different software platforms.

For circular supply chains, consider the Global Circularity Protocol (GCP) for Business, introduced in November 2025 by the WBCSD and UNEP. This protocol includes scopes, indicators, and methods to measure and report circular performance [11]. It works alongside ISO 59020, an international standard tailored for assessing circularity [11].

Certain industries also have specialized standards to address their unique requirements. For example:

UNECE Traceability Standards: Designed for the garment and footwear sectors, offering tools for tracking product origins and materials [3][6][10].

Circular Product Data Protocol: Helps resellers and recyclers access material information for apparel [3][10].

PR3 Standard: Focuses on maintaining consistency in reusable packaging logistics [3].

If your operations involve exports to the EU, prepare for compliance with the Digital Product Passport (DPP) under the Ecodesign for Sustainable Products Regulation. Starting in February 2027, mandatory requirements will apply to textiles, steel, and electronics [9][14].

"Transparency and open data sharing are critical if we are going to progress towards a circular economy. The Circular Product Data Protocol provides the common, open language needed to break down barriers."

Katie Shaw, Chief Programme Officer, Open Apparel Registry[10]

Verify Data Accuracy and Quality

Even with standardized formats, the value of shared data hinges on its accuracy. To ensure reliability, assess data quality through four critical dimensions:

Completeness: Check that all required details are included.

Validity: Confirm data adheres to established rules and formats.

Timeliness: Ensure information is current and relevant.

Consistency: Verify that data aligns across various systems [12].

To strengthen this process, consider technologies like blockchain to create secure, unalterable records and simplify verification. Watch for issues like orphan records (data without clear connections) and dark data (unused or hidden information), and focus on digitizing internal processes before scaling up external data sharing [12][13].

Step 3: Implement Digital Product Passports

A Digital Product Passport (DPP) is essentially a digital record that follows a product throughout its lifecycle. This record includes key details such as material sources, environmental impact, repairability, and recycling potential. By using unique identifiers - like QR codes or RFID tags - stakeholders across the supply chain, from manufacturers to consumers and recyclers, can access this verified information in real time. This system not only supports circular economy goals by enabling better recycling and repair practices but also enhances supply chain security by helping to prevent counterfeit goods. In essence, it ensures that accurate product information is accessible at every stage of the circular supply chain.

If your business involves exporting to the European Union, DPPs will soon be mandatory. Starting in 2026, the Ecodesign for Sustainable Products Regulation will require DPPs for industrial and electric vehicle batteries [16]. The Global Battery Alliance has also taken steps to align with these regulations, launching its "Battery Passport" framework in January 2025. This initiative provides a global standard for tracking ESG parameters across the battery value chain [3].

What Goes Into a Digital Product Passport

To make the most of a DPP, it needs to include specific, actionable data. A well-structured DPP should cover five key areas:

Basic Product Data: Includes the product’s name, model, batch number, manufacturing date, and warranty details.

Material and Sourcing Information: Tracks raw material origins, chemical composition, and any substances of concern.

Sustainability Metrics: Quantifies aspects like carbon footprint, water usage, and energy efficiency.

Circular and Use Data: Details the product’s durability, repairability, maintenance history, and reuse instructions.

End-of-Life Data: Provides information on recyclability, dismantling, and proper disposal methods.

Before creating a DPP, it’s crucial to centralize all product data using systems like Product Information Management (PIM) or Master Data Management (MDM). These tools help establish a single, reliable source of truth. Conducting thorough data audits can identify any gaps, especially in areas like carbon footprint tracking, substances of concern, and repairability.

Technology Options for Digital Product Passports

Several technologies can help manage and implement DPPs effectively:

QR Codes: A straightforward way for consumers to access product details using their smartphones.

RFID and NFC Tags: Ideal for automated data collection in industrial environments, like warehouses or recycling facilities.

Blockchain and Distributed Ledger Technology: Ensures tamper-proof, decentralized records that verify product authenticity and ownership.

Digital Watermarks: Invisible identifiers embedded in products to aid in material sorting during recycling.

APIs: Facilitate seamless data sharing between various supply chain systems.

The European Commission-funded CIRPASS initiative has already laid the groundwork for DPP implementation. In 2025, it conducted pilot programs exploring decentralized data models and digital identifiers for textiles and electronics, helping businesses prepare for upcoming regulations [16]. To ensure smooth cross-border data exchange, consider adopting interoperable technologies, such as those aligned with the United Nations Transparency Protocol [15].

"Digital Product Passports represent a transformative opportunity to address two critical challenges: the unsustainable waste of our linear economy and the vulnerability of our supply chains to counterfeiting and disruption."

Step 4: Build Collaboration with Supply Chain Partners

Once robust data-sharing systems and digital tools are in place, the next step is creating strong, transparent partnerships across the entire supply chain. Transparency in circular supply chains isn’t a solo effort - it relies on active collaboration among suppliers, manufacturers, recyclers, and even customers who return products for reuse. Transitioning from a linear "take-make-waste" model to a circular system requires a two-way flow of data, not just downstream sharing [1]. In this approach, customers can become suppliers of used materials, and industry peers may join forces to circulate resources more efficiently.

The key to improving transparency lies with your partners. Building trust means moving beyond purely transactional relationships. Frameworks that encourage the sharing of verified data benefit everyone involved. Additionally, organizations that provide support - especially to suppliers in low-income countries facing technical or financial challenges - often see higher levels of participation [3].

"Improved traceability and transparency lays the foundation for trust among all actors along the value chain which can encourage more transformational collaboration towards more circular models."

Circular Economy Earth [3]

Establish Collaborative Frameworks

Start by setting clear expectations and criteria for your suppliers. Define specific performance standards for data sharing, material tracking, and circularity metrics. Work together to create shared goals that align with both your transparency objectives and their capabilities.

Regular communication and shared accountability are essential. Implement mechanisms like a "Sustainability Pledge" or similar reporting tools to help track and verify performance [6]. These frameworks are most effective when they directly address concerns about data integrity. For example, when reviewing supplier claims about emissions or material sourcing, ask detailed questions about their methodologies, scope boundaries, and additionality [17]. If a supplier claims to use "low-carbon" materials, confirm whether the allocation is site-specific and proportional, as this method is more credible than virtual mass-balance approaches [17].

Emerging collaborative solutions, such as trusted circular trader programs and resource recovery lanes, offer tangible benefits. These include faster customs processing and fewer administrative hurdles for businesses handling secondary raw materials [3]. Such frameworks don’t just encourage transparency - they reward it with clear, practical incentives.

Use Incentives to Encourage Participation

For transparency efforts to succeed, partners need to see clear business benefits. Sharing data can reduce reliance on volatile virgin resource markets, improving material security [1]. Present transparency as a way to enhance operational resilience, rather than just another compliance requirement.

Financial incentives tied to performance can be particularly effective. Aligning annual bonuses or performance reviews for supply chain teams with circular economy goals can motivate action. Recognizing and rewarding suppliers who develop innovative circular solutions also drives engagement [2]. Some companies even make transparency a condition for contract awards, pairing this requirement with supportive measures to ensure success, rather than relying on penalties alone [17].

For smaller partners who may struggle with the costs of implementing transparency measures, providing technical training and institutional support can make a big difference. This approach not only improves the quality of shared data but also strengthens long-term partnerships and operational efficiency.

At Council Fire, we specialize in helping organizations design collaborative frameworks and incentive systems that bring transparency to life across circular supply chains. By fostering trust and aligning goals, we help businesses achieve lasting results.

Step 5: Establish Audits and Accountability Systems

Audits and accountability systems are essential for verifying data and ensuring partners stick to their commitments. With consumer goods supply chains responsible for over 80% of total greenhouse gas emissions [19][1], these mechanisms play a critical role in safeguarding both environmental goals and business outcomes.

Traditional metrics, like inventory turnover, often miss the mark when it comes to assessing material circulation. To truly measure progress, audits should focus on product durability, circularity rates, and waste diversion. Integrating these factors into both financial and sustainability reporting lays the groundwork for regular evaluations that strengthen every link in your circular supply chain.

Schedule Regular Audits and Inspections

Third-party audits, such as those conducted through the Responsible Business Alliance's Validated Assessment Program [22], provide an impartial layer of validation. Pair these with digital tools like Digital Product Passports, blockchain, and IoT sensors, which offer tamper-proof, real-time tracking of products throughout their life cycle.

A notable example is the Global Battery Alliance's "Battery Passport" initiative, which creates a global framework for auditing ESG factors across the battery value chain [3]. This model demonstrates how technology can enhance transparency and accountability.

To ensure compliance, embed circularity requirements into supplier qualification processes and legal agreements [19]. Clearly state that participation in audit programs is a prerequisite for doing business. For suppliers working with secondary raw materials, consider joining trusted circular trader programs. These programs can simplify customs processes and reduce administrative burdens in exchange for verified transparency [3].

Social audits should also be part of the equation. With 20 million informal waste workers globally [3], these checks ensure fair pay and safe working conditions, preventing exploitation within your circular supply chain.

Track Performance with Key Metrics

Audits are not just about compliance - they’re a tool for driving ongoing improvement. Frameworks like Circulytics [18] and Circular Transition Indicators [3] provide clear metrics to measure circular performance. The Global Circularity Protocol v1.0 offers a structured approach aligned with the ESRS and the GHG Protocol, allowing organizations to monitor material flows and evaluate impacts on climate, nature, equity, and business outcomes [11].

"Measuring and reporting on progress towards circular economy outcomes is a key driver in the transition to the circular economy. It plays a powerful role in setting direction, showing progress, identifying opportunities, and demonstrating impact."

Ellen MacArthur Foundation [18]

Accountability can also be tied directly to employee performance. For instance, annual bonuses and evaluations can hinge on meeting specific circular KPIs [19]. At the facility level, tools like the Responsible Business Alliance's Waste Tracking Record Tool offer straightforward and consistent reporting across multiple sites [20].

Globally, 73% of the largest 250 companies use the GRI Standard for structured reporting [21]. Adopting such recognized standards ensures that your metrics are both credible and comparable across industries. Furthermore, leveraging spend data and AI can help identify "emission hotspots" and high-impact ESG areas within your supplier base, allowing you to allocate audit resources where they’ll make the biggest difference [21].

At Council Fire, we specialize in designing audit systems and accountability frameworks that keep your circular supply chain transparent and effective.

Step 6: Train Your Teams on Transparency Systems

Once you've established mapping, data protocols, digital passports, collaboration, and audits, the next step is equipping your teams to effectively use these transparency systems. These tools are only as effective as the people managing them. Considering that supply chain leaders oversee an astounding 100 billion tonnes of materials globally and that 88% of projects succeed with strong change management practices [1][23], training becomes a cornerstone for advancing circular economy goals.

It's not just about technical skills; it's also about helping employees connect transparency systems to broader environmental and business objectives. When teams see how their work contributes to these larger goals, they’re more likely to embrace the changes.

Deliver Role-Specific Training

Training should be tailored to the specific needs of each team. For example:

Sustainability leaders need to navigate complex regulations like CBAM and ESPR. They must choose the best greenhouse gas reporting framework - whether it’s the GHG Protocol or the PACT Methodology - and use tools like decision trees to align their strategies with goals such as disclosure or emissions reduction [17].

Procurement teams must learn how to verify claims about "low-carbon" products and avoid greenwashing. Their training should include understanding scope boundaries, interpreting mass balance models, assessing "additionality" (whether a green solution supports transformative technologies), and distinguishing between pre-consumer and post-consumer scrap content. They must also verify that carbon certificates come from credible registries [17].

Suppliers, particularly those in low-income regions, often need additional support to align with international transparency standards. Providing them with capacity-building programs and training on tools like Digital Product Passports can be transformative [3].

"Supply chain leaders are fundamental players in the transition to a circular economy. They are responsible for sourcing and moving 100 billion tonnes of materials that enter the global economy each year."

Ellen MacArthur Foundation [1]

This role-specific training ensures that the data-sharing and audit systems developed earlier are seamlessly integrated into daily workflows.

Apply Change Management Practices

In addition to training, employing effective change management strategies ensures that new systems and practices take hold across the organization. The ADKAR model - focused on Awareness, Desire, Knowledge, Ability, and Reinforcement - serves as a practical framework for guiding employees through the transition [24]. Start by clearly explaining the importance of the changes, then provide comprehensive training and hands-on support as employees build new skills. Reinforce these efforts consistently until the new practices become second nature.

Appointing change champions can help bridge the gap between leadership’s vision and the reality of frontline execution [24]. Engaging employees in decision-making increases success rates by 15% [23], and establishing feedback loops allows teams to voice concerns and offer suggestions for improvement.

Resistance is inevitable, but it can be addressed head-on with dedicated support sessions. When 21% of global services decision-makers cite implementing new processes as a major challenge in digital transformation [23], offering hands-on assistance and clear role definitions through tools like a RACI matrix can make all the difference [24].

"Training is a key part of transparency. It fosters collaboration and strong partnerships, creating a culture of diligence and accountability."

Amazon Business [25]

Embedding transparency systems into daily operations is critical to sustaining these changes over time. Regular check-ins can help capture lessons learned and document successful practices for future initiatives. Research shows that transformation efforts are three times more likely to succeed when they include clear communication, a supportive culture, and a commitment to continuous improvement [23]. These training and change management efforts ensure that transparency and accountability remain integral to your circular supply chain.

At Council Fire, we specialize in helping organizations design training programs and change management strategies that empower teams to maintain transparency and accountability at every step of the supply chain.

Conclusion

Building transparency into circular supply chains lays the groundwork for lasting success. By taking steps such as mapping your supply chain, standardizing how data is shared, adopting digital product passports, fostering collaboration with partners, conducting audits, and training your teams, you create a system that delivers measurable benefits throughout your operations.

Given that supply chains account for over 80% of total emissions [1], transparency plays a critical role in driving real environmental progress. Beyond environmental concerns, transparent supply chains also enhance resilience by minimizing risks tied to price fluctuations and supply disruptions. Clear data enables cost savings by making remanufacturing more efficient than producing new goods, while streamlined material flows improve inventory management and reduce waste.

Transparency fosters trust among stakeholders. When organizations can back up their claims with verifiable data and demonstrate accountability, they gain access to circular business models like leasing and sharing. They also stay ahead of regulatory changes, such as Extended Producer Responsibility (EPR) and eco-design requirements. Additionally, transparency helps uphold ethical standards across the supply chain, supporting the fair treatment of the approximately 20 million informal waste workers globally who depend on these systems [3].

Achieving true transparency demands dedication and expert support. Effective circular systems rely on accurate data and strong partnerships. At Council Fire, we assist organizations in turning sustainability goals into actionable strategies - whether it’s creating data-sharing frameworks or developing stakeholder engagement plans that drive meaningful results. From mapping material flows to refining data protocols, expert guidance can help you deliver enduring environmental, social, and economic benefits.

FAQs

What role do Digital Product Passports play in improving transparency in circular supply chains?

Digital Product Passports are transforming transparency by compiling and sharing comprehensive details about a product's entire lifecycle. This includes specifics like material sourcing, environmental effects, adherence to regulations, and recycling possibilities. By making such information available to everyone involved in the supply chain, these passports promote accountability and enable smarter, more informed decisions.

For businesses and consumers alike, these passports serve as a tool to confirm a product’s sustainability and its alignment with circular practices. They build trust and encourage collaboration within the supply chain, playing a key role in advancing a more transparent and circular economic model.

What is the role of informal waste workers in creating transparency in circular supply chains?

Informal waste workers, commonly known as waste pickers, play a vital role in circular supply chains. They are often the first link in the reverse logistics process, collecting, sorting, and aggregating post-consumer materials. This work offers a valuable chance to gather essential data - such as material type, weight, and origin - that can be digitized to ensure greater transparency from the point of collection onward.

Including these workers in traceability systems not only allows organizations to monitor material flows but also provides insights into important social factors like worker safety, gender inclusion, and fair labor practices. By formalizing their contributions - whether through cooperatives or data-sharing platforms - companies can ensure even the most marginalized individuals are part of the supply chain. This approach supports broader goals of equity and sustainability.

Council Fire collaborates with organizations to create inclusive frameworks that bring informal waste workers into the fold. This not only helps companies achieve ESG targets but also strengthens accountability and builds more resilient circular supply chains.

How can companies ensure accurate data for transparency in circular supply chains?

To achieve reliable transparency, companies should begin by conducting a thorough audit of their current records. This involves mapping all relevant data sources - such as procurement, production, logistics, and product life cycle management - and cataloging critical details like material composition, supplier data, energy consumption, waste streams, and certifications. This process not only highlights outdated, missing, or redundant information but also establishes a solid foundation for future improvements.

Implementing standardized data frameworks and widely recognized identifier systems is another essential step. Consistency can be achieved by using uniform fields, such as material grade, country of origin, and certification codes, which help minimize manual errors and streamline automated validation. Regular cross-referencing with trusted third-party systems further enhances data accuracy and reliability.

Accountability is key to maintaining these efforts. Assigning data stewards to oversee critical metrics, resolve discrepancies, and ensure adherence to relevant standards embeds responsibility into the process. Additionally, equipping staff with proper training in data management and establishing clear ownership policies ensures that transparency initiatives remain effective and actionable.

Related Blog Posts

Latest Articles

©2025

FAQ

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Jan 4, 2026

How to Ensure Transparency in Circular Supply Chains

Sustainability Strategy

In This Article

True circularity depends on end-to-end transparency: map flows, standardize data, use digital product passports, audit partners, and train teams.

How to Ensure Transparency in Circular Supply Chains

Transparency is the backbone of circular supply chains, enabling efficient material reuse, ethical practices, and reduced emissions. Here's how organizations can achieve it:

Map the Supply Chain: Identify all participants, including informal waste workers, and track material flows from extraction to recovery.

Standardize Data Sharing: Use global standards like GS1 or protocols such as the Global Circularity Protocol to ensure consistent and reliable data exchange.

Implement Digital Product Passports (DPPs): Equip products with QR codes or RFID tags to provide lifecycle details, aiding repair, recycling, and compliance with regulations like the EU's Ecodesign directive.

Collaborate with Partners: Build trust by setting clear expectations, offering incentives, and supporting smaller suppliers with training and resources.

Conduct Audits: Use third-party audits and tools like blockchain to verify data accuracy and track circularity metrics.

Train Teams: Equip employees with role-specific knowledge to manage transparency systems effectively, ensuring long-term success.

Why it matters: Supply chains contribute over 80% of emissions in consumer goods industries. Transparency not only supports material recovery and ethical practices but also helps businesses meet regulatory demands, reduce risks, and build trust with stakeholders.

6 Steps to Achieve Transparency in Circular Supply Chains

Using Digital Traceability to Drive Supply Chain Transparency

Step 1: Map Your Complete Supply Chain

To create a comprehensive view of your supply chain, document every participant and movement of materials, starting from raw material extraction and extending all the way to material recovery. Circular systems are complex, with multidirectional flows where customers can become suppliers and recyclers play a vital role in returning materials to the system [1][2]. Begin by breaking down the chain to identify key stakeholders and material flows.

Identify Stakeholders and Material Flows

Start by listing all key players in your supply chain, such as direct suppliers, manufacturers, distributors, repair services, and recyclers. Don’t forget the informal sector, which includes approximately 20 million informal waste workers worldwide. These workers are critical for collecting and processing materials, yet they are often left out of traditional supply chain maps [4]. Including them is essential for creating a truly circular system. Organizations can also [empower communities] (https://www.councilfire.org/future-leaders-program) by integrating these workers into formal structures.

Focus on identifying key suppliers, particularly those responsible for 75–80% of your spending or those linked to high brand risks. Record crucial details such as chemical compositions, sourcing origins, purchase orders, quality standards, and disassembly options. This information ensures better management and transparency throughout the supply chain [3][5].

Use Supply Chain Mapping Tools

Once you’ve outlined stakeholders and material flows, use specialized tools to visualize and analyze your supply chain. Platforms like Circularise, Provenance, Circulor, TraceX, and Reath can enhance traceability and provide a clearer picture of your value chain [3]. To measure circularity performance, explore frameworks like WBCSD's Circular Transition Indicators, the Ellen MacArthur Foundation's Circulytics, or BCG's CIRCelligence [3][7].

If informal waste pickers or recyclers are part of your supply chain, tools like BanQu and Plastic Bank are designed to map their activities and improve transparency. These platforms not only highlight their contributions but also ensure fair compensation, bringing visibility to the entire material recovery process [3]. By integrating these tools, you can create a more inclusive and transparent supply chain.

Step 2: Set Up Standardized Data Sharing Protocols

Once you've mapped your supply chain, the next step is to ensure all partners are speaking the same "data language." Without a standardized approach, critical details can get lost, creating bottlenecks in transparency. The key is to implement global data-sharing standards that provide a unified framework for documenting and exchanging information. This builds on your supply chain map, ensuring that data flows remain consistent and dependable.

Adopt Global Data Sharing Standards

A good starting point is the GS1 Global Traceability Standard [8][9]. This framework enables organizations to identify, capture, and share product information in a common language, making data exchange smoother across different software platforms.

For circular supply chains, consider the Global Circularity Protocol (GCP) for Business, introduced in November 2025 by the WBCSD and UNEP. This protocol includes scopes, indicators, and methods to measure and report circular performance [11]. It works alongside ISO 59020, an international standard tailored for assessing circularity [11].

Certain industries also have specialized standards to address their unique requirements. For example:

UNECE Traceability Standards: Designed for the garment and footwear sectors, offering tools for tracking product origins and materials [3][6][10].

Circular Product Data Protocol: Helps resellers and recyclers access material information for apparel [3][10].

PR3 Standard: Focuses on maintaining consistency in reusable packaging logistics [3].

If your operations involve exports to the EU, prepare for compliance with the Digital Product Passport (DPP) under the Ecodesign for Sustainable Products Regulation. Starting in February 2027, mandatory requirements will apply to textiles, steel, and electronics [9][14].

"Transparency and open data sharing are critical if we are going to progress towards a circular economy. The Circular Product Data Protocol provides the common, open language needed to break down barriers."

Katie Shaw, Chief Programme Officer, Open Apparel Registry[10]

Verify Data Accuracy and Quality

Even with standardized formats, the value of shared data hinges on its accuracy. To ensure reliability, assess data quality through four critical dimensions:

Completeness: Check that all required details are included.

Validity: Confirm data adheres to established rules and formats.

Timeliness: Ensure information is current and relevant.

Consistency: Verify that data aligns across various systems [12].

To strengthen this process, consider technologies like blockchain to create secure, unalterable records and simplify verification. Watch for issues like orphan records (data without clear connections) and dark data (unused or hidden information), and focus on digitizing internal processes before scaling up external data sharing [12][13].

Step 3: Implement Digital Product Passports

A Digital Product Passport (DPP) is essentially a digital record that follows a product throughout its lifecycle. This record includes key details such as material sources, environmental impact, repairability, and recycling potential. By using unique identifiers - like QR codes or RFID tags - stakeholders across the supply chain, from manufacturers to consumers and recyclers, can access this verified information in real time. This system not only supports circular economy goals by enabling better recycling and repair practices but also enhances supply chain security by helping to prevent counterfeit goods. In essence, it ensures that accurate product information is accessible at every stage of the circular supply chain.

If your business involves exporting to the European Union, DPPs will soon be mandatory. Starting in 2026, the Ecodesign for Sustainable Products Regulation will require DPPs for industrial and electric vehicle batteries [16]. The Global Battery Alliance has also taken steps to align with these regulations, launching its "Battery Passport" framework in January 2025. This initiative provides a global standard for tracking ESG parameters across the battery value chain [3].

What Goes Into a Digital Product Passport

To make the most of a DPP, it needs to include specific, actionable data. A well-structured DPP should cover five key areas:

Basic Product Data: Includes the product’s name, model, batch number, manufacturing date, and warranty details.

Material and Sourcing Information: Tracks raw material origins, chemical composition, and any substances of concern.

Sustainability Metrics: Quantifies aspects like carbon footprint, water usage, and energy efficiency.

Circular and Use Data: Details the product’s durability, repairability, maintenance history, and reuse instructions.

End-of-Life Data: Provides information on recyclability, dismantling, and proper disposal methods.

Before creating a DPP, it’s crucial to centralize all product data using systems like Product Information Management (PIM) or Master Data Management (MDM). These tools help establish a single, reliable source of truth. Conducting thorough data audits can identify any gaps, especially in areas like carbon footprint tracking, substances of concern, and repairability.

Technology Options for Digital Product Passports

Several technologies can help manage and implement DPPs effectively:

QR Codes: A straightforward way for consumers to access product details using their smartphones.

RFID and NFC Tags: Ideal for automated data collection in industrial environments, like warehouses or recycling facilities.

Blockchain and Distributed Ledger Technology: Ensures tamper-proof, decentralized records that verify product authenticity and ownership.

Digital Watermarks: Invisible identifiers embedded in products to aid in material sorting during recycling.

APIs: Facilitate seamless data sharing between various supply chain systems.

The European Commission-funded CIRPASS initiative has already laid the groundwork for DPP implementation. In 2025, it conducted pilot programs exploring decentralized data models and digital identifiers for textiles and electronics, helping businesses prepare for upcoming regulations [16]. To ensure smooth cross-border data exchange, consider adopting interoperable technologies, such as those aligned with the United Nations Transparency Protocol [15].

"Digital Product Passports represent a transformative opportunity to address two critical challenges: the unsustainable waste of our linear economy and the vulnerability of our supply chains to counterfeiting and disruption."

Step 4: Build Collaboration with Supply Chain Partners

Once robust data-sharing systems and digital tools are in place, the next step is creating strong, transparent partnerships across the entire supply chain. Transparency in circular supply chains isn’t a solo effort - it relies on active collaboration among suppliers, manufacturers, recyclers, and even customers who return products for reuse. Transitioning from a linear "take-make-waste" model to a circular system requires a two-way flow of data, not just downstream sharing [1]. In this approach, customers can become suppliers of used materials, and industry peers may join forces to circulate resources more efficiently.

The key to improving transparency lies with your partners. Building trust means moving beyond purely transactional relationships. Frameworks that encourage the sharing of verified data benefit everyone involved. Additionally, organizations that provide support - especially to suppliers in low-income countries facing technical or financial challenges - often see higher levels of participation [3].

"Improved traceability and transparency lays the foundation for trust among all actors along the value chain which can encourage more transformational collaboration towards more circular models."

Circular Economy Earth [3]

Establish Collaborative Frameworks

Start by setting clear expectations and criteria for your suppliers. Define specific performance standards for data sharing, material tracking, and circularity metrics. Work together to create shared goals that align with both your transparency objectives and their capabilities.

Regular communication and shared accountability are essential. Implement mechanisms like a "Sustainability Pledge" or similar reporting tools to help track and verify performance [6]. These frameworks are most effective when they directly address concerns about data integrity. For example, when reviewing supplier claims about emissions or material sourcing, ask detailed questions about their methodologies, scope boundaries, and additionality [17]. If a supplier claims to use "low-carbon" materials, confirm whether the allocation is site-specific and proportional, as this method is more credible than virtual mass-balance approaches [17].

Emerging collaborative solutions, such as trusted circular trader programs and resource recovery lanes, offer tangible benefits. These include faster customs processing and fewer administrative hurdles for businesses handling secondary raw materials [3]. Such frameworks don’t just encourage transparency - they reward it with clear, practical incentives.

Use Incentives to Encourage Participation

For transparency efforts to succeed, partners need to see clear business benefits. Sharing data can reduce reliance on volatile virgin resource markets, improving material security [1]. Present transparency as a way to enhance operational resilience, rather than just another compliance requirement.

Financial incentives tied to performance can be particularly effective. Aligning annual bonuses or performance reviews for supply chain teams with circular economy goals can motivate action. Recognizing and rewarding suppliers who develop innovative circular solutions also drives engagement [2]. Some companies even make transparency a condition for contract awards, pairing this requirement with supportive measures to ensure success, rather than relying on penalties alone [17].

For smaller partners who may struggle with the costs of implementing transparency measures, providing technical training and institutional support can make a big difference. This approach not only improves the quality of shared data but also strengthens long-term partnerships and operational efficiency.

At Council Fire, we specialize in helping organizations design collaborative frameworks and incentive systems that bring transparency to life across circular supply chains. By fostering trust and aligning goals, we help businesses achieve lasting results.

Step 5: Establish Audits and Accountability Systems

Audits and accountability systems are essential for verifying data and ensuring partners stick to their commitments. With consumer goods supply chains responsible for over 80% of total greenhouse gas emissions [19][1], these mechanisms play a critical role in safeguarding both environmental goals and business outcomes.

Traditional metrics, like inventory turnover, often miss the mark when it comes to assessing material circulation. To truly measure progress, audits should focus on product durability, circularity rates, and waste diversion. Integrating these factors into both financial and sustainability reporting lays the groundwork for regular evaluations that strengthen every link in your circular supply chain.

Schedule Regular Audits and Inspections

Third-party audits, such as those conducted through the Responsible Business Alliance's Validated Assessment Program [22], provide an impartial layer of validation. Pair these with digital tools like Digital Product Passports, blockchain, and IoT sensors, which offer tamper-proof, real-time tracking of products throughout their life cycle.

A notable example is the Global Battery Alliance's "Battery Passport" initiative, which creates a global framework for auditing ESG factors across the battery value chain [3]. This model demonstrates how technology can enhance transparency and accountability.

To ensure compliance, embed circularity requirements into supplier qualification processes and legal agreements [19]. Clearly state that participation in audit programs is a prerequisite for doing business. For suppliers working with secondary raw materials, consider joining trusted circular trader programs. These programs can simplify customs processes and reduce administrative burdens in exchange for verified transparency [3].

Social audits should also be part of the equation. With 20 million informal waste workers globally [3], these checks ensure fair pay and safe working conditions, preventing exploitation within your circular supply chain.

Track Performance with Key Metrics

Audits are not just about compliance - they’re a tool for driving ongoing improvement. Frameworks like Circulytics [18] and Circular Transition Indicators [3] provide clear metrics to measure circular performance. The Global Circularity Protocol v1.0 offers a structured approach aligned with the ESRS and the GHG Protocol, allowing organizations to monitor material flows and evaluate impacts on climate, nature, equity, and business outcomes [11].

"Measuring and reporting on progress towards circular economy outcomes is a key driver in the transition to the circular economy. It plays a powerful role in setting direction, showing progress, identifying opportunities, and demonstrating impact."

Ellen MacArthur Foundation [18]

Accountability can also be tied directly to employee performance. For instance, annual bonuses and evaluations can hinge on meeting specific circular KPIs [19]. At the facility level, tools like the Responsible Business Alliance's Waste Tracking Record Tool offer straightforward and consistent reporting across multiple sites [20].

Globally, 73% of the largest 250 companies use the GRI Standard for structured reporting [21]. Adopting such recognized standards ensures that your metrics are both credible and comparable across industries. Furthermore, leveraging spend data and AI can help identify "emission hotspots" and high-impact ESG areas within your supplier base, allowing you to allocate audit resources where they’ll make the biggest difference [21].

At Council Fire, we specialize in designing audit systems and accountability frameworks that keep your circular supply chain transparent and effective.

Step 6: Train Your Teams on Transparency Systems

Once you've established mapping, data protocols, digital passports, collaboration, and audits, the next step is equipping your teams to effectively use these transparency systems. These tools are only as effective as the people managing them. Considering that supply chain leaders oversee an astounding 100 billion tonnes of materials globally and that 88% of projects succeed with strong change management practices [1][23], training becomes a cornerstone for advancing circular economy goals.

It's not just about technical skills; it's also about helping employees connect transparency systems to broader environmental and business objectives. When teams see how their work contributes to these larger goals, they’re more likely to embrace the changes.

Deliver Role-Specific Training

Training should be tailored to the specific needs of each team. For example:

Sustainability leaders need to navigate complex regulations like CBAM and ESPR. They must choose the best greenhouse gas reporting framework - whether it’s the GHG Protocol or the PACT Methodology - and use tools like decision trees to align their strategies with goals such as disclosure or emissions reduction [17].

Procurement teams must learn how to verify claims about "low-carbon" products and avoid greenwashing. Their training should include understanding scope boundaries, interpreting mass balance models, assessing "additionality" (whether a green solution supports transformative technologies), and distinguishing between pre-consumer and post-consumer scrap content. They must also verify that carbon certificates come from credible registries [17].

Suppliers, particularly those in low-income regions, often need additional support to align with international transparency standards. Providing them with capacity-building programs and training on tools like Digital Product Passports can be transformative [3].

"Supply chain leaders are fundamental players in the transition to a circular economy. They are responsible for sourcing and moving 100 billion tonnes of materials that enter the global economy each year."

Ellen MacArthur Foundation [1]

This role-specific training ensures that the data-sharing and audit systems developed earlier are seamlessly integrated into daily workflows.

Apply Change Management Practices

In addition to training, employing effective change management strategies ensures that new systems and practices take hold across the organization. The ADKAR model - focused on Awareness, Desire, Knowledge, Ability, and Reinforcement - serves as a practical framework for guiding employees through the transition [24]. Start by clearly explaining the importance of the changes, then provide comprehensive training and hands-on support as employees build new skills. Reinforce these efforts consistently until the new practices become second nature.

Appointing change champions can help bridge the gap between leadership’s vision and the reality of frontline execution [24]. Engaging employees in decision-making increases success rates by 15% [23], and establishing feedback loops allows teams to voice concerns and offer suggestions for improvement.

Resistance is inevitable, but it can be addressed head-on with dedicated support sessions. When 21% of global services decision-makers cite implementing new processes as a major challenge in digital transformation [23], offering hands-on assistance and clear role definitions through tools like a RACI matrix can make all the difference [24].

"Training is a key part of transparency. It fosters collaboration and strong partnerships, creating a culture of diligence and accountability."

Amazon Business [25]

Embedding transparency systems into daily operations is critical to sustaining these changes over time. Regular check-ins can help capture lessons learned and document successful practices for future initiatives. Research shows that transformation efforts are three times more likely to succeed when they include clear communication, a supportive culture, and a commitment to continuous improvement [23]. These training and change management efforts ensure that transparency and accountability remain integral to your circular supply chain.

At Council Fire, we specialize in helping organizations design training programs and change management strategies that empower teams to maintain transparency and accountability at every step of the supply chain.

Conclusion

Building transparency into circular supply chains lays the groundwork for lasting success. By taking steps such as mapping your supply chain, standardizing how data is shared, adopting digital product passports, fostering collaboration with partners, conducting audits, and training your teams, you create a system that delivers measurable benefits throughout your operations.

Given that supply chains account for over 80% of total emissions [1], transparency plays a critical role in driving real environmental progress. Beyond environmental concerns, transparent supply chains also enhance resilience by minimizing risks tied to price fluctuations and supply disruptions. Clear data enables cost savings by making remanufacturing more efficient than producing new goods, while streamlined material flows improve inventory management and reduce waste.

Transparency fosters trust among stakeholders. When organizations can back up their claims with verifiable data and demonstrate accountability, they gain access to circular business models like leasing and sharing. They also stay ahead of regulatory changes, such as Extended Producer Responsibility (EPR) and eco-design requirements. Additionally, transparency helps uphold ethical standards across the supply chain, supporting the fair treatment of the approximately 20 million informal waste workers globally who depend on these systems [3].

Achieving true transparency demands dedication and expert support. Effective circular systems rely on accurate data and strong partnerships. At Council Fire, we assist organizations in turning sustainability goals into actionable strategies - whether it’s creating data-sharing frameworks or developing stakeholder engagement plans that drive meaningful results. From mapping material flows to refining data protocols, expert guidance can help you deliver enduring environmental, social, and economic benefits.

FAQs

What role do Digital Product Passports play in improving transparency in circular supply chains?

Digital Product Passports are transforming transparency by compiling and sharing comprehensive details about a product's entire lifecycle. This includes specifics like material sourcing, environmental effects, adherence to regulations, and recycling possibilities. By making such information available to everyone involved in the supply chain, these passports promote accountability and enable smarter, more informed decisions.

For businesses and consumers alike, these passports serve as a tool to confirm a product’s sustainability and its alignment with circular practices. They build trust and encourage collaboration within the supply chain, playing a key role in advancing a more transparent and circular economic model.

What is the role of informal waste workers in creating transparency in circular supply chains?

Informal waste workers, commonly known as waste pickers, play a vital role in circular supply chains. They are often the first link in the reverse logistics process, collecting, sorting, and aggregating post-consumer materials. This work offers a valuable chance to gather essential data - such as material type, weight, and origin - that can be digitized to ensure greater transparency from the point of collection onward.

Including these workers in traceability systems not only allows organizations to monitor material flows but also provides insights into important social factors like worker safety, gender inclusion, and fair labor practices. By formalizing their contributions - whether through cooperatives or data-sharing platforms - companies can ensure even the most marginalized individuals are part of the supply chain. This approach supports broader goals of equity and sustainability.

Council Fire collaborates with organizations to create inclusive frameworks that bring informal waste workers into the fold. This not only helps companies achieve ESG targets but also strengthens accountability and builds more resilient circular supply chains.

How can companies ensure accurate data for transparency in circular supply chains?

To achieve reliable transparency, companies should begin by conducting a thorough audit of their current records. This involves mapping all relevant data sources - such as procurement, production, logistics, and product life cycle management - and cataloging critical details like material composition, supplier data, energy consumption, waste streams, and certifications. This process not only highlights outdated, missing, or redundant information but also establishes a solid foundation for future improvements.

Implementing standardized data frameworks and widely recognized identifier systems is another essential step. Consistency can be achieved by using uniform fields, such as material grade, country of origin, and certification codes, which help minimize manual errors and streamline automated validation. Regular cross-referencing with trusted third-party systems further enhances data accuracy and reliability.

Accountability is key to maintaining these efforts. Assigning data stewards to oversee critical metrics, resolve discrepancies, and ensure adherence to relevant standards embeds responsibility into the process. Additionally, equipping staff with proper training in data management and establishing clear ownership policies ensures that transparency initiatives remain effective and actionable.

Related Blog Posts

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Jan 4, 2026

How to Ensure Transparency in Circular Supply Chains

Sustainability Strategy

In This Article

True circularity depends on end-to-end transparency: map flows, standardize data, use digital product passports, audit partners, and train teams.

How to Ensure Transparency in Circular Supply Chains

Transparency is the backbone of circular supply chains, enabling efficient material reuse, ethical practices, and reduced emissions. Here's how organizations can achieve it:

Map the Supply Chain: Identify all participants, including informal waste workers, and track material flows from extraction to recovery.

Standardize Data Sharing: Use global standards like GS1 or protocols such as the Global Circularity Protocol to ensure consistent and reliable data exchange.

Implement Digital Product Passports (DPPs): Equip products with QR codes or RFID tags to provide lifecycle details, aiding repair, recycling, and compliance with regulations like the EU's Ecodesign directive.

Collaborate with Partners: Build trust by setting clear expectations, offering incentives, and supporting smaller suppliers with training and resources.

Conduct Audits: Use third-party audits and tools like blockchain to verify data accuracy and track circularity metrics.

Train Teams: Equip employees with role-specific knowledge to manage transparency systems effectively, ensuring long-term success.

Why it matters: Supply chains contribute over 80% of emissions in consumer goods industries. Transparency not only supports material recovery and ethical practices but also helps businesses meet regulatory demands, reduce risks, and build trust with stakeholders.

6 Steps to Achieve Transparency in Circular Supply Chains

Using Digital Traceability to Drive Supply Chain Transparency

Step 1: Map Your Complete Supply Chain

To create a comprehensive view of your supply chain, document every participant and movement of materials, starting from raw material extraction and extending all the way to material recovery. Circular systems are complex, with multidirectional flows where customers can become suppliers and recyclers play a vital role in returning materials to the system [1][2]. Begin by breaking down the chain to identify key stakeholders and material flows.

Identify Stakeholders and Material Flows

Start by listing all key players in your supply chain, such as direct suppliers, manufacturers, distributors, repair services, and recyclers. Don’t forget the informal sector, which includes approximately 20 million informal waste workers worldwide. These workers are critical for collecting and processing materials, yet they are often left out of traditional supply chain maps [4]. Including them is essential for creating a truly circular system. Organizations can also [empower communities] (https://www.councilfire.org/future-leaders-program) by integrating these workers into formal structures.

Focus on identifying key suppliers, particularly those responsible for 75–80% of your spending or those linked to high brand risks. Record crucial details such as chemical compositions, sourcing origins, purchase orders, quality standards, and disassembly options. This information ensures better management and transparency throughout the supply chain [3][5].

Use Supply Chain Mapping Tools

Once you’ve outlined stakeholders and material flows, use specialized tools to visualize and analyze your supply chain. Platforms like Circularise, Provenance, Circulor, TraceX, and Reath can enhance traceability and provide a clearer picture of your value chain [3]. To measure circularity performance, explore frameworks like WBCSD's Circular Transition Indicators, the Ellen MacArthur Foundation's Circulytics, or BCG's CIRCelligence [3][7].

If informal waste pickers or recyclers are part of your supply chain, tools like BanQu and Plastic Bank are designed to map their activities and improve transparency. These platforms not only highlight their contributions but also ensure fair compensation, bringing visibility to the entire material recovery process [3]. By integrating these tools, you can create a more inclusive and transparent supply chain.

Step 2: Set Up Standardized Data Sharing Protocols

Once you've mapped your supply chain, the next step is to ensure all partners are speaking the same "data language." Without a standardized approach, critical details can get lost, creating bottlenecks in transparency. The key is to implement global data-sharing standards that provide a unified framework for documenting and exchanging information. This builds on your supply chain map, ensuring that data flows remain consistent and dependable.

Adopt Global Data Sharing Standards

A good starting point is the GS1 Global Traceability Standard [8][9]. This framework enables organizations to identify, capture, and share product information in a common language, making data exchange smoother across different software platforms.

For circular supply chains, consider the Global Circularity Protocol (GCP) for Business, introduced in November 2025 by the WBCSD and UNEP. This protocol includes scopes, indicators, and methods to measure and report circular performance [11]. It works alongside ISO 59020, an international standard tailored for assessing circularity [11].

Certain industries also have specialized standards to address their unique requirements. For example:

UNECE Traceability Standards: Designed for the garment and footwear sectors, offering tools for tracking product origins and materials [3][6][10].

Circular Product Data Protocol: Helps resellers and recyclers access material information for apparel [3][10].

PR3 Standard: Focuses on maintaining consistency in reusable packaging logistics [3].

If your operations involve exports to the EU, prepare for compliance with the Digital Product Passport (DPP) under the Ecodesign for Sustainable Products Regulation. Starting in February 2027, mandatory requirements will apply to textiles, steel, and electronics [9][14].

"Transparency and open data sharing are critical if we are going to progress towards a circular economy. The Circular Product Data Protocol provides the common, open language needed to break down barriers."

Katie Shaw, Chief Programme Officer, Open Apparel Registry[10]

Verify Data Accuracy and Quality

Even with standardized formats, the value of shared data hinges on its accuracy. To ensure reliability, assess data quality through four critical dimensions:

Completeness: Check that all required details are included.

Validity: Confirm data adheres to established rules and formats.

Timeliness: Ensure information is current and relevant.

Consistency: Verify that data aligns across various systems [12].

To strengthen this process, consider technologies like blockchain to create secure, unalterable records and simplify verification. Watch for issues like orphan records (data without clear connections) and dark data (unused or hidden information), and focus on digitizing internal processes before scaling up external data sharing [12][13].

Step 3: Implement Digital Product Passports

A Digital Product Passport (DPP) is essentially a digital record that follows a product throughout its lifecycle. This record includes key details such as material sources, environmental impact, repairability, and recycling potential. By using unique identifiers - like QR codes or RFID tags - stakeholders across the supply chain, from manufacturers to consumers and recyclers, can access this verified information in real time. This system not only supports circular economy goals by enabling better recycling and repair practices but also enhances supply chain security by helping to prevent counterfeit goods. In essence, it ensures that accurate product information is accessible at every stage of the circular supply chain.

If your business involves exporting to the European Union, DPPs will soon be mandatory. Starting in 2026, the Ecodesign for Sustainable Products Regulation will require DPPs for industrial and electric vehicle batteries [16]. The Global Battery Alliance has also taken steps to align with these regulations, launching its "Battery Passport" framework in January 2025. This initiative provides a global standard for tracking ESG parameters across the battery value chain [3].

What Goes Into a Digital Product Passport

To make the most of a DPP, it needs to include specific, actionable data. A well-structured DPP should cover five key areas:

Basic Product Data: Includes the product’s name, model, batch number, manufacturing date, and warranty details.

Material and Sourcing Information: Tracks raw material origins, chemical composition, and any substances of concern.

Sustainability Metrics: Quantifies aspects like carbon footprint, water usage, and energy efficiency.

Circular and Use Data: Details the product’s durability, repairability, maintenance history, and reuse instructions.

End-of-Life Data: Provides information on recyclability, dismantling, and proper disposal methods.

Before creating a DPP, it’s crucial to centralize all product data using systems like Product Information Management (PIM) or Master Data Management (MDM). These tools help establish a single, reliable source of truth. Conducting thorough data audits can identify any gaps, especially in areas like carbon footprint tracking, substances of concern, and repairability.

Technology Options for Digital Product Passports

Several technologies can help manage and implement DPPs effectively:

QR Codes: A straightforward way for consumers to access product details using their smartphones.

RFID and NFC Tags: Ideal for automated data collection in industrial environments, like warehouses or recycling facilities.

Blockchain and Distributed Ledger Technology: Ensures tamper-proof, decentralized records that verify product authenticity and ownership.

Digital Watermarks: Invisible identifiers embedded in products to aid in material sorting during recycling.

APIs: Facilitate seamless data sharing between various supply chain systems.

The European Commission-funded CIRPASS initiative has already laid the groundwork for DPP implementation. In 2025, it conducted pilot programs exploring decentralized data models and digital identifiers for textiles and electronics, helping businesses prepare for upcoming regulations [16]. To ensure smooth cross-border data exchange, consider adopting interoperable technologies, such as those aligned with the United Nations Transparency Protocol [15].

"Digital Product Passports represent a transformative opportunity to address two critical challenges: the unsustainable waste of our linear economy and the vulnerability of our supply chains to counterfeiting and disruption."

Step 4: Build Collaboration with Supply Chain Partners

Once robust data-sharing systems and digital tools are in place, the next step is creating strong, transparent partnerships across the entire supply chain. Transparency in circular supply chains isn’t a solo effort - it relies on active collaboration among suppliers, manufacturers, recyclers, and even customers who return products for reuse. Transitioning from a linear "take-make-waste" model to a circular system requires a two-way flow of data, not just downstream sharing [1]. In this approach, customers can become suppliers of used materials, and industry peers may join forces to circulate resources more efficiently.

The key to improving transparency lies with your partners. Building trust means moving beyond purely transactional relationships. Frameworks that encourage the sharing of verified data benefit everyone involved. Additionally, organizations that provide support - especially to suppliers in low-income countries facing technical or financial challenges - often see higher levels of participation [3].

"Improved traceability and transparency lays the foundation for trust among all actors along the value chain which can encourage more transformational collaboration towards more circular models."

Circular Economy Earth [3]

Establish Collaborative Frameworks

Start by setting clear expectations and criteria for your suppliers. Define specific performance standards for data sharing, material tracking, and circularity metrics. Work together to create shared goals that align with both your transparency objectives and their capabilities.

Regular communication and shared accountability are essential. Implement mechanisms like a "Sustainability Pledge" or similar reporting tools to help track and verify performance [6]. These frameworks are most effective when they directly address concerns about data integrity. For example, when reviewing supplier claims about emissions or material sourcing, ask detailed questions about their methodologies, scope boundaries, and additionality [17]. If a supplier claims to use "low-carbon" materials, confirm whether the allocation is site-specific and proportional, as this method is more credible than virtual mass-balance approaches [17].

Emerging collaborative solutions, such as trusted circular trader programs and resource recovery lanes, offer tangible benefits. These include faster customs processing and fewer administrative hurdles for businesses handling secondary raw materials [3]. Such frameworks don’t just encourage transparency - they reward it with clear, practical incentives.

Use Incentives to Encourage Participation

For transparency efforts to succeed, partners need to see clear business benefits. Sharing data can reduce reliance on volatile virgin resource markets, improving material security [1]. Present transparency as a way to enhance operational resilience, rather than just another compliance requirement.

Financial incentives tied to performance can be particularly effective. Aligning annual bonuses or performance reviews for supply chain teams with circular economy goals can motivate action. Recognizing and rewarding suppliers who develop innovative circular solutions also drives engagement [2]. Some companies even make transparency a condition for contract awards, pairing this requirement with supportive measures to ensure success, rather than relying on penalties alone [17].

For smaller partners who may struggle with the costs of implementing transparency measures, providing technical training and institutional support can make a big difference. This approach not only improves the quality of shared data but also strengthens long-term partnerships and operational efficiency.

At Council Fire, we specialize in helping organizations design collaborative frameworks and incentive systems that bring transparency to life across circular supply chains. By fostering trust and aligning goals, we help businesses achieve lasting results.

Step 5: Establish Audits and Accountability Systems

Audits and accountability systems are essential for verifying data and ensuring partners stick to their commitments. With consumer goods supply chains responsible for over 80% of total greenhouse gas emissions [19][1], these mechanisms play a critical role in safeguarding both environmental goals and business outcomes.

Traditional metrics, like inventory turnover, often miss the mark when it comes to assessing material circulation. To truly measure progress, audits should focus on product durability, circularity rates, and waste diversion. Integrating these factors into both financial and sustainability reporting lays the groundwork for regular evaluations that strengthen every link in your circular supply chain.

Schedule Regular Audits and Inspections

Third-party audits, such as those conducted through the Responsible Business Alliance's Validated Assessment Program [22], provide an impartial layer of validation. Pair these with digital tools like Digital Product Passports, blockchain, and IoT sensors, which offer tamper-proof, real-time tracking of products throughout their life cycle.

A notable example is the Global Battery Alliance's "Battery Passport" initiative, which creates a global framework for auditing ESG factors across the battery value chain [3]. This model demonstrates how technology can enhance transparency and accountability.

To ensure compliance, embed circularity requirements into supplier qualification processes and legal agreements [19]. Clearly state that participation in audit programs is a prerequisite for doing business. For suppliers working with secondary raw materials, consider joining trusted circular trader programs. These programs can simplify customs processes and reduce administrative burdens in exchange for verified transparency [3].

Social audits should also be part of the equation. With 20 million informal waste workers globally [3], these checks ensure fair pay and safe working conditions, preventing exploitation within your circular supply chain.

Track Performance with Key Metrics

Audits are not just about compliance - they’re a tool for driving ongoing improvement. Frameworks like Circulytics [18] and Circular Transition Indicators [3] provide clear metrics to measure circular performance. The Global Circularity Protocol v1.0 offers a structured approach aligned with the ESRS and the GHG Protocol, allowing organizations to monitor material flows and evaluate impacts on climate, nature, equity, and business outcomes [11].

"Measuring and reporting on progress towards circular economy outcomes is a key driver in the transition to the circular economy. It plays a powerful role in setting direction, showing progress, identifying opportunities, and demonstrating impact."

Ellen MacArthur Foundation [18]

Accountability can also be tied directly to employee performance. For instance, annual bonuses and evaluations can hinge on meeting specific circular KPIs [19]. At the facility level, tools like the Responsible Business Alliance's Waste Tracking Record Tool offer straightforward and consistent reporting across multiple sites [20].

Globally, 73% of the largest 250 companies use the GRI Standard for structured reporting [21]. Adopting such recognized standards ensures that your metrics are both credible and comparable across industries. Furthermore, leveraging spend data and AI can help identify "emission hotspots" and high-impact ESG areas within your supplier base, allowing you to allocate audit resources where they’ll make the biggest difference [21].

At Council Fire, we specialize in designing audit systems and accountability frameworks that keep your circular supply chain transparent and effective.

Step 6: Train Your Teams on Transparency Systems

Once you've established mapping, data protocols, digital passports, collaboration, and audits, the next step is equipping your teams to effectively use these transparency systems. These tools are only as effective as the people managing them. Considering that supply chain leaders oversee an astounding 100 billion tonnes of materials globally and that 88% of projects succeed with strong change management practices [1][23], training becomes a cornerstone for advancing circular economy goals.

It's not just about technical skills; it's also about helping employees connect transparency systems to broader environmental and business objectives. When teams see how their work contributes to these larger goals, they’re more likely to embrace the changes.

Deliver Role-Specific Training

Training should be tailored to the specific needs of each team. For example:

Sustainability leaders need to navigate complex regulations like CBAM and ESPR. They must choose the best greenhouse gas reporting framework - whether it’s the GHG Protocol or the PACT Methodology - and use tools like decision trees to align their strategies with goals such as disclosure or emissions reduction [17].