Dec 31, 2025

Dec 31, 2025

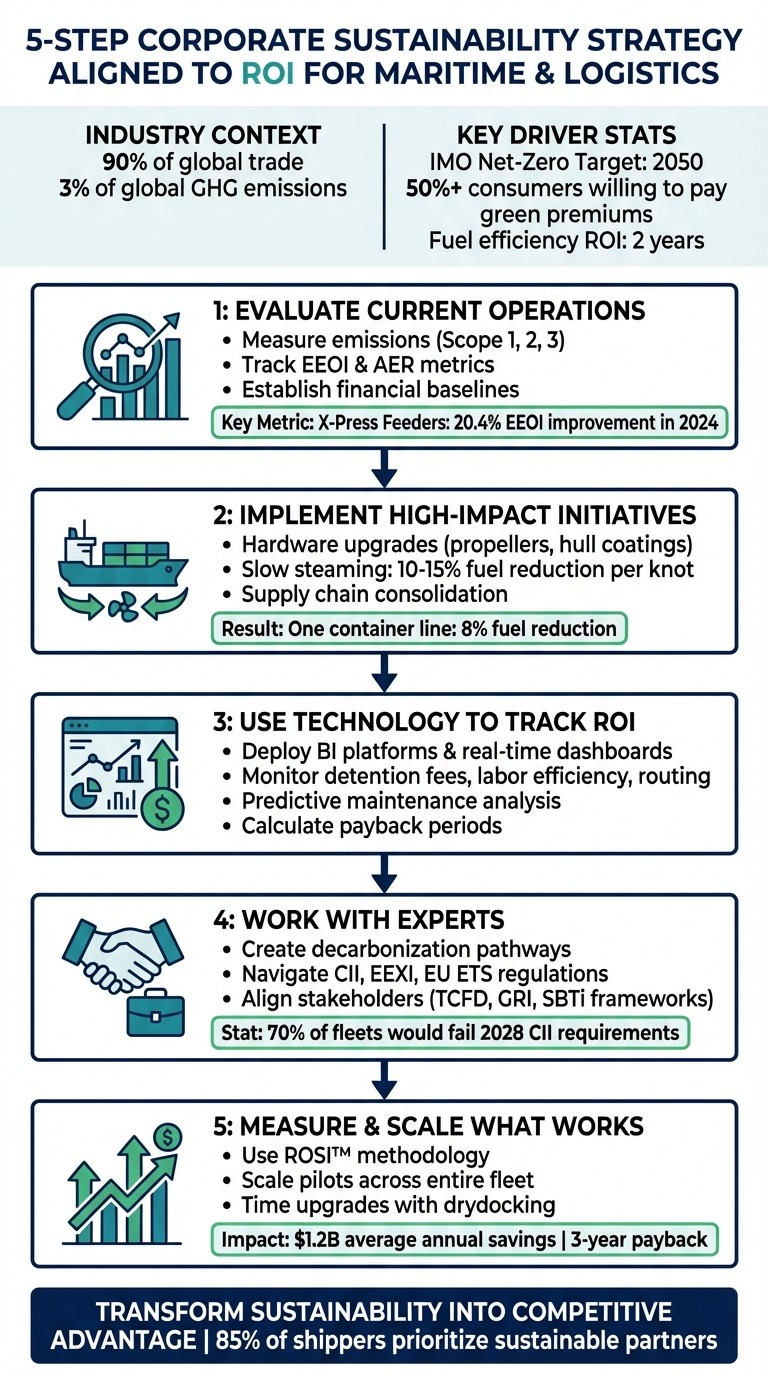

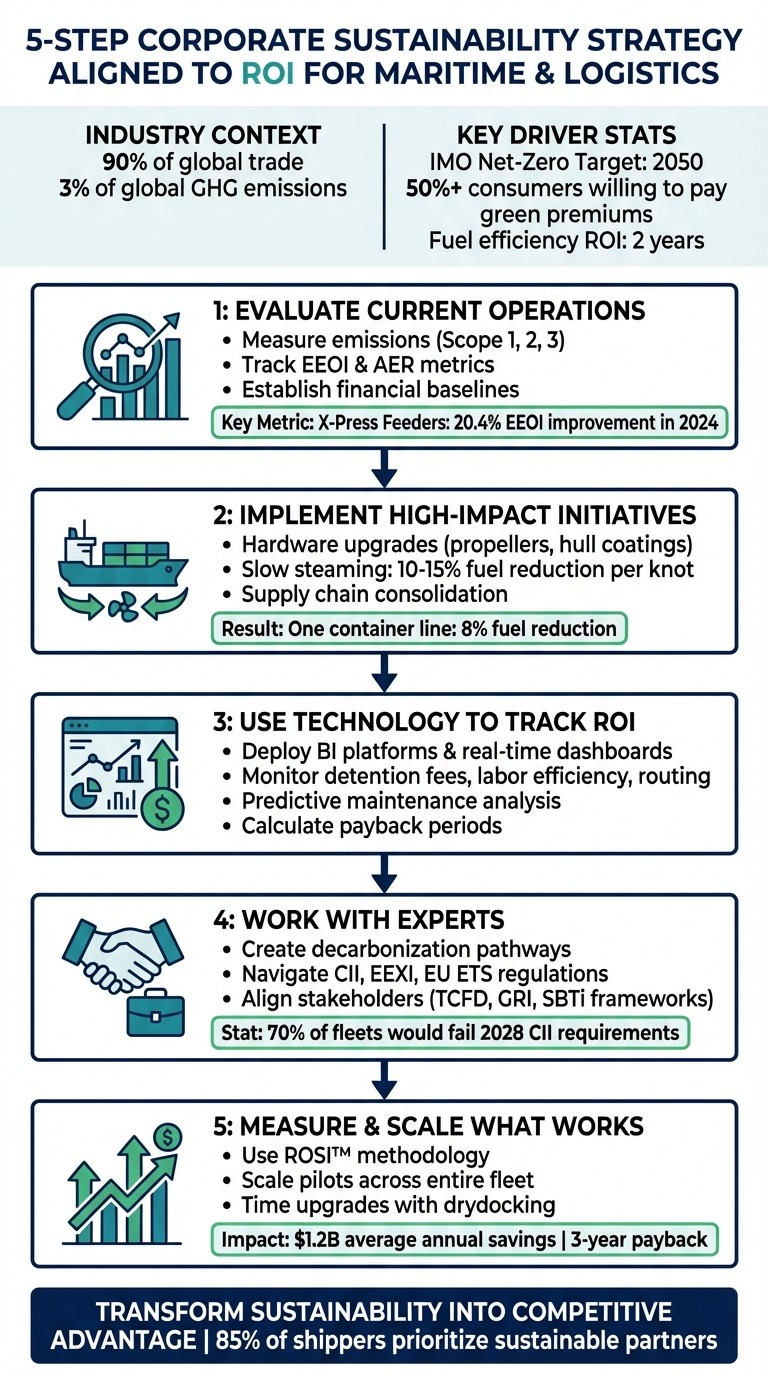

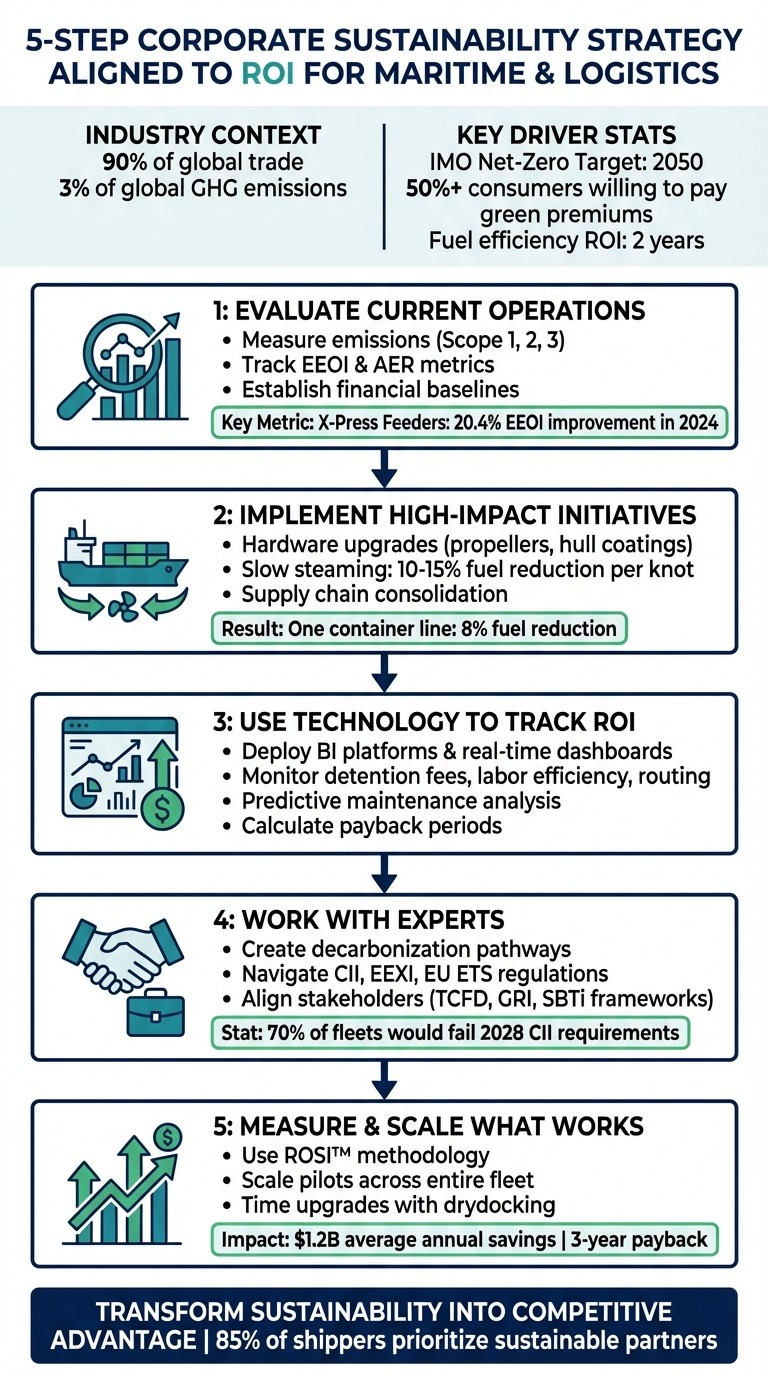

How to Build a Corporate Sustainability Strategy Aligned to ROI for Maritime & Logistics Companies

Sustainability Strategy

Sustainability Strategy

In This Article

Align maritime and logistics sustainability with ROI: measure Scope 1–3, prioritize fuel efficiency and tech, engage experts, and scale proven pilots.

How to Build a Corporate Sustainability Strategy Aligned to ROI for Maritime & Logistics Companies

The maritime and logistics industry, responsible for 90% of global trade, contributes 3% of global greenhouse gas emissions. With stricter regulations, customer demands, and financial pressures, sustainability is no longer optional. Companies must align sustainability efforts with financial returns to stay competitive.

Key Takeaways:

Regulatory Compliance: The IMO aims for net-zero emissions by 2050, with regional policies enforcing stricter standards.

Customer Demands: Major cargo owners like Amazon and Ikea push for zero-carbon shipping by 2040.

Financial Opportunities: Over 50% of consumers are willing to pay premiums for sustainable shipping, and fuel efficiency upgrades can pay off within two years.

Steps to Build a Strategy:

Evaluate Current Operations: Measure emissions (Scope 1, 2, 3) and establish financial baselines.

Implement Fuel-Efficiency Initiatives: Use hardware upgrades, slow steaming, and supply chain optimizations.

Leverage Technology: Deploy tools to track ROI and improve decision-making.

Engage Experts: Collaborate with specialists for decarbonization pathways and regulatory compliance.

Scale Effective Initiatives: Expand successful pilots across fleets or supply chains for broader impact.

By integrating measurable goals and focusing on cost-effective solutions, maritime and logistics companies can align environmental goals with profitability.

5-Step Corporate Sustainability Strategy for Maritime & Logistics Companies

Building an Actionable Maritime Decarbonization Strategy with Berge Bulk and Sofar Ocean

Step 1: Evaluate Current Operations and Set ROI Baselines

Before diving into new initiatives, it's essential to understand where you currently stand. Begin by assessing your environmental impact and establishing clear financial benchmarks. These baselines are your starting point for tracking improvements and determining whether your investments deliver measurable returns. Start by quantifying both your carbon footprint and financial exposure.

Measure Your Carbon Footprint

To calculate your emissions effectively, use the GHG Protocol Standard [9], which divides emissions into three categories, or "scopes":

Scope 1: Direct emissions from assets you own or operate, such as vessel fuel use and refrigerants [8].

Scope 2: Indirect emissions from purchased electricity for offices, warehouses, and port terminals [8].

Scope 3: Often the largest category for maritime companies, covering emissions from upstream fuel production, purchased goods, employee travel, and outsourced transportation [9][8].

For maritime operations, it's also crucial to track intensity metrics like the Energy Efficiency Operational Indicator (EEOI) and the Annual Efficiency Ratio (AER). These metrics measure carbon intensity per unit of work, such as grams of CO₂ per ton-mile, providing insights into operational efficiency [8]. For example, in 2024, X-Press Feeders achieved an EEOI of 20.430 gCO₂e/MT-Nm, reflecting a 20.4% improvement from the previous year. Their AER for owned vessels improved by 20.0% year-over-year, reaching 10.358 gCO₂/DWT-Nm. Both metrics were independently verified by ClassNK [8].

When addressing Scope 3 emissions, prioritize suppliers that account for 75% to 80% of your spending or those with energy-intensive activities [4]. For smaller supply chain partners, simplify the data collection process with tools like the EPA's Simplified GHG Emissions Calculator or straightforward questionnaires to encourage high response rates [4].

By integrating these environmental metrics with financial data, you’ll establish a robust ROI baseline that aligns operational performance with sustainability goals.

Select Key ROI Metrics

To evaluate the financial impact of your sustainability efforts, incorporate both defensive and offensive ROI metrics into your baseline:

Defensive Metrics: Quantify risks such as regulatory fines, carbon taxes, and potential market share losses. For example, in heavily regulated industries, non-compliance fines can reduce EBITDA by an average of 0.75% over a decade [7].

Offensive Metrics: Track cost savings from fuel efficiency improvements, potential revenue from green premiums (price increases for low-carbon services), and reduced recruitment costs due to higher employee morale [4][7]. Notably, products marketed as sustainable have shown a 28% cumulative growth over five years compared to 20% for non-sustainable products [7].

Establish a "base case" financial forecast using your historical financial and sustainability data before implementing new strategies [7]. This benchmark will help you determine whether your investments are driving positive returns.

Metric Category | Specific Data Point | Purpose for ROI Baseline |

|---|---|---|

Environmental | Scope 1, 2, & 3 Emissions | Measure total carbon footprint and regulatory exposure [8] |

Environmental | EEOI / AER | Track operational efficiency and fuel-to-cargo ratios [8] |

Financial | Fuel Consumption Costs | Baseline for savings from efficiency or alternative fuels [4] |

Financial | Green Premiums | Identify potential revenue growth from sustainable services [7] |

Financial | Regulatory/Legal Risk | Quantify potential costs of non-compliance or carbon taxes [7] |

These benchmarks serve as the foundation for the next steps, where you'll leverage technology and specialized expertise to optimize operations and enhance sustainability.

Step 2: Implement High-Impact Sustainability Initiatives

Once baseline metrics are established, the next step is to roll out initiatives that cut emissions while delivering measurable cost savings. The focus should be on reducing fuel consumption and operational waste - areas where environmental benefits align directly with financial efficiency.

Improve Fuel Efficiency

Fuel expenses rank among the highest operating costs in maritime operations. Upgrading hardware, such as installing propeller devices, applying high-performance hull coatings, or retrofitting bulbous bows, can yield returns within two years. For instance, one container line successfully reduced fuel consumption by 8% through such measures[1]. Additionally, slowing vessel speeds - known as slow steaming - can cut fuel use by 10% to 15% with just a one-knot reduction. Pairing these efforts with analytics-driven sailing optimization, which considers factors like weather, currents, port readiness, and fuel prices, can further enhance efficiency. Scheduling retrofits during planned dry dock periods and adopting a "Design-to-Value" strategy for new vessel construction can ensure maximum return on investment[1]. These steps lay the groundwork for broader supply chain improvements.

Make Your Supply Chain More Sustainable

In addition to vessel upgrades, refining supply chain processes can lead to significant savings. Consolidating shipments reduces the number of trips required, lowering both per-unit transportation costs and fuel consumption. Cutting back on overpackaging not only saves on materials but also reduces fuel use during transport[6]. For inland logistics, electrification is key - electric vehicles for heavy-duty trucking and last-mile deliveries can cut fuel costs while meeting stricter urban emissions regulations[2]. Warehousing offers opportunities as well: installing solar panels on large rooftops can power lighting and HVAC systems, sometimes even producing surplus energy for the grid. Automated storage and retrieval systems enhance picking accuracy while reducing energy waste[2].

When selecting carriers and logistics partners, prioritize those with verified emissions data and strong efficiency programs, especially those accounting for 75% to 80% of your spending. Frameworks like the EPA's SmartWay program can serve as valuable tools for benchmarking performance without the need to develop internal tracking systems from scratch[4][6].

Step 3: Use Technology and Data to Track ROI

Start leveraging digital tools to measure the operational benefits of recent fuel and supply chain upgrades [11]. Once these enhancements are in place, the focus shifts to determining whether they are delivering the expected returns. Without effective tracking systems, it becomes challenging to assess the value of your sustainability investments or identify areas for further improvement.

Use Data-Driven Tools

Business Intelligence platforms and real-time dashboards are invaluable for connecting operational changes to financial outcomes. These tools consolidate data from systems like Transportation Management, Warehouse Management, and dock scheduling, providing a comprehensive view of performance [11]. Key metrics to monitor include reduced detention fees, improved labor efficiency, and optimized vessel routing [11]. By linking operational changes to measurable financial results, these insights provide a clear picture of your progress.

Before rolling out new digital tools, document baseline metrics to enable clear comparisons between pre- and post-implementation performance [11]. After deployment, calculate time-based savings using actual costs. For instance, if carrier wait times are reduced by 30 minutes per truck across 500 trucks monthly, apply the average hourly cost of trucks and drivers to determine savings [11]. In 2024, A.P. Moller – Maersk expanded its sustainable fleet by introducing seven dual-fuel vessels capable of running on green methanol, alongside the retrofitted Maersk Halifax - the first dual-fuel methanol container vessel in the industry. These efforts align with the company’s goal of achieving net-zero greenhouse gas emissions by 2040 [3]. Pairing these tools with predictive maintenance analysis can uncover even more operational savings [11].

Track Predictive Maintenance Savings

Predictive technologies like digital routing and dock scheduling systems help reduce fuel consumption by incorporating real-time data on variables like weather, currents, and port readiness [11]. These platforms use "Planned vs. Actual" analyses to identify inefficiencies and cut down on idle times for vessels [11]. Meanwhile, automated storage and retrieval systems in warehouses reduce energy usage by operating in the dark and improving picking accuracy [10][2]. To measure the return on investment (ROI) of these technologies, apply the payback period formula: divide the investment cost by the annual benefits [11].

"The ability to accurately measure the Return on Investment (ROI) of a dock scheduling system is no longer a 'nice-to-have'; it's a fundamental component of strategic decision-making." - QueueMe [11]

When calculating ROI, include all associated costs, such as software licenses, implementation, configuration, staff training, and ongoing maintenance. Overlooking these expenses can lead to inflated ROI figures and complicate justifications for future investments [11]. Beyond financial metrics, digital tools can also strengthen carrier relationships and reduce the stress of manual coordination via email and phone [11]. These actionable insights not only reinforce the alignment of sustainability goals with financial returns but also lay the groundwork for scaling these initiatives effectively in future steps.

Step 4: Work with Experts to Implement Your Strategy

Once you’ve established a clear return on investment (ROI) baseline and identified effective sustainability initiatives, it’s time to bring in specialized expertise. Developing a sustainability strategy that delivers measurable results often demands skills and knowledge that many maritime and logistics companies lack internally. While 90% of executives prioritize sustainability, only 60% have formal strategies in place, and nearly half struggle to measure ROI effectively [2][12]. This gap between ambition and execution highlights the importance of expert guidance.

Collaborate with Experts to Create Decarbonization Pathways

Specialized consultants can recommend proven and adaptable measures that yield ROI, regardless of which future fuel becomes dominant [1][13]. For instance, a prominent container shipping company worked closely with technical experts to implement over 400 hardware upgrades across 150 vessels. By optimizing components such as propellers, bulbous bows, and internal boilers, the company successfully reduced total fuel consumption by 8% [1].

Experts also leverage advanced tools like Fleet Decarbonization Optimizers to calculate detailed costs at the vessel level. These tools help pinpoint the most cost-effective strategies, spanning fleet hardware upgrades, fuel choices, and commercial approaches [1]. Moreover, consultants play a key role in navigating complex regulations like the Carbon Intensity Indicator (CII), Energy Efficiency Existing Ship Index (EEXI), and the European Union Emissions Trading System (EU ETS). This guidance is essential, especially considering that roughly 70% of the global tanker and container fleets would have failed to meet 2028 CII requirements based on their 2018 performance [1].

Beyond regulatory compliance, consultants help build comprehensive business cases that go beyond immediate cost reductions. These include cutting waste, capturing "green premiums" to drive revenue, managing risks through compliance, and enhancing brand reputation [12].

"The transition to zero carbon can be a value-generating opportunity for shipping companies - if they are proactive and purposeful, rather than reactive and defensive." – McKinsey Travel, Logistics & Infrastructure Practice [1]

Align Stakeholders for Greater Impact

Sustainability efforts thrive on collaboration, but misaligned priorities often create challenges. In fact, 62% of companies report disagreements between boards and management on sustainability goals [14]. Expert consultants can bridge these gaps by using established frameworks like the Task Force on Climate-Related Financial Disclosures (TCFD), Global Reporting Initiative (GRI), and Science-Based Targets initiative (SBTi). These tools streamline the process of assessing climate risks and tracking progress, eliminating the need to start from scratch [14].

Additionally, consultants help manage pressures from shareholders, regulators, customers, and lenders regarding environmental, social, and governance (ESG) performance. They can also assist in segmenting customers based on their Scope 3 emissions goals, enabling you to prioritize "green" shipping services for those willing to pay a premium for decarbonized solutions [1]. This strategic focus not only transforms sustainability into a competitive advantage but also positions your company to capture market share while others remain mired in indecision. By aligning stakeholders and focusing on measurable outcomes, expert guidance lays the groundwork for scalable and impactful results.

Step 5: Measure Results and Scale What Works

Once sustainability initiatives are in motion, the next step is to evaluate their financial impact and expand successful practices. Companies actively addressing environmental concerns report an average of $1.2 billion in annual savings from emission-reduction projects, with supply chain initiatives typically paying off within three years [15]. The key challenge lies in transitioning from small-scale pilots to comprehensive, organization-wide transformations that yield measurable returns.

Use ROI Frameworks to Show Impact

Traditional accounting often fails to capture the complete financial value of sustainability investments. By adopting impact-weighted accounts, companies can assign monetary value to social, human, and environmental benefits [17]. This method highlights that intangible benefits, such as improved brand reputation and enhanced employee engagement, can be worth 4 to 10 times more than tangible cost savings [17].

The ROSI™ (Return on Sustainability Investment) methodology, developed by NYU Stern Center for Sustainable Business, connects sustainability strategies with financial performance. It aligns ROI metrics with those used by finance teams, going beyond direct cost reductions to include "avoided costs" through risk mitigation, "enabled value" from new revenue sources like green contracts, and "soft benefits" such as higher talent retention [15][17]. For example, maritime companies can track metrics like AER (Annual Efficiency Ratio) and EEOI (Energy Efficiency Operational Indicator) to measure improvements. In 2024, X-Press Feeders achieved a 20.4% year-over-year improvement in EEOI and a 20.0% improvement in AER by deploying dual-fuel vessels powered by green methanol. These results were independently verified by ClassNK [8].

"The green bottom line is a robust, multi-faceted, and compelling financial reality." – RNG Strategy Consulting [15]

These frameworks provide the necessary validation for pilot projects, paving the way for broader implementation.

Expand High-Impact Initiatives

Once pilot projects demonstrate solid ROI, the next step is to scale these initiatives across the organization. Leading shipping companies, for instance, see greater returns by applying energy-saving solutions like hull coatings and propeller upgrades to their entire fleet portfolio, rather than limiting them to individual vessels [18]. For example, propeller ducts can improve efficiency by 2% to 9% over a vessel's lifetime, with a payback period of just three to four years [18]. A major container line reduced fuel consumption by 8% after making over 400 modifications to 150 vessels [1].

Scaling requires efficient processes and robust data systems to ensure consistency [16]. Timing sustainability upgrades with regular operational cycles - such as implementing hardware retrofits during scheduled drydocking - minimizes downtime and reduces costs [1]. For example, a leading consumer packaged goods (CPG) company forecasts annual savings of $200 million and expects to avoid $400 million in cumulative costs by 2030 through improvements in manufacturing and logistics [7].

Adopting a pilot-and-fund model can also be effective, where savings from initial projects finance larger-scale initiatives [15]. For instance, a 3% improvement in On-Time-In-Full delivery, achieved through better supply chain visibility, can boost top-line revenue by 1% [19]. This approach ensures that successful initiatives are not only sustained but also expanded to drive long-term value.

Conclusion: Turn Sustainability into a Competitive Advantage

The maritime and logistics industry stands at a critical crossroads. While many executives recognize the importance of sustainability, few have implemented formal strategies to address it [2]. This gap presents a clear opportunity for companies willing to act with purpose. By prioritizing sustainability, businesses can unlock green premiums, secure alternative fuel sources, and enhance operational resilience.

Key Takeaways for Maritime & Logistics Leaders

To align sustainability with profitability, treat carbon reduction as equally important as efficiency and cost. This approach, often referred to as the "triangle of optimization", ensures that environmental goals complement, rather than compete with, financial objectives [5]. Companies that act early - securing alternative fuel supplies and upgrading hardware during routine maintenance - position themselves as forward-thinking leaders in the green transition. Notably, 85% of shippers are expected to prioritize sustainability when selecting partners [1].

The most effective organizations focus on initiatives with immediate impact and manageable payback periods, such as improving propeller designs and applying advanced hull coatings. Simultaneously, they invest in long-term strategies like green fuel procurement and fleet electrification. Leading companies also engage suppliers strategically, link executive compensation to sustainability performance, and use data-driven tools to pinpoint investments with the highest net present value. McKinsey highlights this proactive approach:

"The transition to zero carbon can be a value-generating opportunity for shipping companies - if they are proactive and purposeful, rather than reactive and defensive" [1].

These practices provide a clear framework for taking meaningful action.

Next Steps to Put Your Strategy into Action

Start by establishing a clear baseline for your current emissions and operational costs. Focus on the 75% to 80% of suppliers that account for the majority of your spending or reputational exposure, and launch targeted engagement programs [4]. Pilot impactful initiatives like speed optimization and fuel-efficient hardware upgrades, rigorously measure their financial returns, and expand successful efforts across your entire fleet. By taking these steps, companies can transform sustainability from a challenge into a competitive edge.

FAQs

How can maritime companies measure their carbon footprint and assess the ROI of sustainability efforts?

To gauge their carbon footprint, maritime companies should begin with standardized frameworks and robust data collection practices. This means monitoring factors like fuel consumption, engine efficiency, and voyage-specific metrics, then applying emission factors to calculate CO₂e emissions per nautical mile or per unit of cargo transported. Leveraging digital tools that provide real-time insights into fuel usage and vessel performance can significantly improve the precision of these calculations.

When evaluating return on investment (ROI), companies can tie emission reductions directly to cost savings, especially through decreased fuel usage. Cutting CO₂ emissions often translates into lower fuel expenses, offering immediate financial benefits. Beyond cost savings, sustainability efforts can deliver strategic advantages, such as appealing to customers who prioritize low-carbon shipping options, earning regulatory incentives, or commanding higher prices for environmentally conscious services. By integrating precise emissions tracking with a thorough analysis of cost efficiencies and revenue opportunities, maritime companies can effectively showcase the economic benefits of their green initiatives.

What are the most effective ways for maritime logistics companies to reduce emissions while improving ROI?

Reducing emissions in maritime logistics involves a mix of technological advancements, fuel alternatives, and operational improvements, which can also yield measurable financial returns.

Implementing practices such as slow steaming, hull cleaning, propeller upgrades, and advanced weather routing can cut fuel consumption by 5-15% per voyage. These measures not only lower emissions but also reduce operating costs. Transitioning to low-carbon fuels like LNG, green ammonia, or biofuels, alongside integrating wind-assisted propulsion systems such as retrofitted sails, further reduces carbon footprints while supporting long-term sustainability goals.

Another impactful strategy is the use of shore-side electricity (cold ironing) at ports, which eliminates emissions during docking. Meanwhile, digital tools for emissions monitoring provide real-time data, allowing companies to track progress and optimize operations. By adopting these approaches, maritime logistics firms can significantly cut greenhouse gas emissions, boost profitability, and contribute to global sustainability objectives, benefiting both the industry and its stakeholders.

How can logistics companies use technology to track and improve the ROI of sustainability efforts?

Technology is empowering logistics companies to transform sustainability efforts into measurable financial benefits through real-time data, analytics, and automation. Take dock-scheduling platforms, for instance - they provide insights into metrics like berth utilization, idling times, and fuel consumption. By improving scheduling, companies can cut costs tied to fuel usage, overtime pay, and equipment wear. These measurable outcomes can be directly linked to ROI calculations, making the financial benefits of sustainability initiatives more transparent.

Advanced tools such as IoT sensors, AI-driven route optimization, and digital simulations further enhance efficiency. IoT devices monitor fuel consumption and engine performance, while AI evaluates optimal routes or alternative fuel options to minimize emissions. The data generated by these technologies not only highlights cost savings but also helps businesses benchmark their performance against industry standards.

When these systems are integrated into a unified platform, companies gain the ability to continuously track emissions reductions, fuel savings, and operational improvements. This creates a feedback loop where every action is measured, its financial return is quantified, and the insights guide future strategies. This approach ensures sustainability efforts not only support environmental goals but also drive profitability and strengthen stakeholder value.

Related Blog Posts

Latest Articles

©2025

FAQ

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Dec 31, 2025

How to Build a Corporate Sustainability Strategy Aligned to ROI for Maritime & Logistics Companies

Sustainability Strategy

In This Article

Align maritime and logistics sustainability with ROI: measure Scope 1–3, prioritize fuel efficiency and tech, engage experts, and scale proven pilots.

How to Build a Corporate Sustainability Strategy Aligned to ROI for Maritime & Logistics Companies

The maritime and logistics industry, responsible for 90% of global trade, contributes 3% of global greenhouse gas emissions. With stricter regulations, customer demands, and financial pressures, sustainability is no longer optional. Companies must align sustainability efforts with financial returns to stay competitive.

Key Takeaways:

Regulatory Compliance: The IMO aims for net-zero emissions by 2050, with regional policies enforcing stricter standards.

Customer Demands: Major cargo owners like Amazon and Ikea push for zero-carbon shipping by 2040.

Financial Opportunities: Over 50% of consumers are willing to pay premiums for sustainable shipping, and fuel efficiency upgrades can pay off within two years.

Steps to Build a Strategy:

Evaluate Current Operations: Measure emissions (Scope 1, 2, 3) and establish financial baselines.

Implement Fuel-Efficiency Initiatives: Use hardware upgrades, slow steaming, and supply chain optimizations.

Leverage Technology: Deploy tools to track ROI and improve decision-making.

Engage Experts: Collaborate with specialists for decarbonization pathways and regulatory compliance.

Scale Effective Initiatives: Expand successful pilots across fleets or supply chains for broader impact.

By integrating measurable goals and focusing on cost-effective solutions, maritime and logistics companies can align environmental goals with profitability.

5-Step Corporate Sustainability Strategy for Maritime & Logistics Companies

Building an Actionable Maritime Decarbonization Strategy with Berge Bulk and Sofar Ocean

Step 1: Evaluate Current Operations and Set ROI Baselines

Before diving into new initiatives, it's essential to understand where you currently stand. Begin by assessing your environmental impact and establishing clear financial benchmarks. These baselines are your starting point for tracking improvements and determining whether your investments deliver measurable returns. Start by quantifying both your carbon footprint and financial exposure.

Measure Your Carbon Footprint

To calculate your emissions effectively, use the GHG Protocol Standard [9], which divides emissions into three categories, or "scopes":

Scope 1: Direct emissions from assets you own or operate, such as vessel fuel use and refrigerants [8].

Scope 2: Indirect emissions from purchased electricity for offices, warehouses, and port terminals [8].

Scope 3: Often the largest category for maritime companies, covering emissions from upstream fuel production, purchased goods, employee travel, and outsourced transportation [9][8].

For maritime operations, it's also crucial to track intensity metrics like the Energy Efficiency Operational Indicator (EEOI) and the Annual Efficiency Ratio (AER). These metrics measure carbon intensity per unit of work, such as grams of CO₂ per ton-mile, providing insights into operational efficiency [8]. For example, in 2024, X-Press Feeders achieved an EEOI of 20.430 gCO₂e/MT-Nm, reflecting a 20.4% improvement from the previous year. Their AER for owned vessels improved by 20.0% year-over-year, reaching 10.358 gCO₂/DWT-Nm. Both metrics were independently verified by ClassNK [8].

When addressing Scope 3 emissions, prioritize suppliers that account for 75% to 80% of your spending or those with energy-intensive activities [4]. For smaller supply chain partners, simplify the data collection process with tools like the EPA's Simplified GHG Emissions Calculator or straightforward questionnaires to encourage high response rates [4].

By integrating these environmental metrics with financial data, you’ll establish a robust ROI baseline that aligns operational performance with sustainability goals.

Select Key ROI Metrics

To evaluate the financial impact of your sustainability efforts, incorporate both defensive and offensive ROI metrics into your baseline:

Defensive Metrics: Quantify risks such as regulatory fines, carbon taxes, and potential market share losses. For example, in heavily regulated industries, non-compliance fines can reduce EBITDA by an average of 0.75% over a decade [7].

Offensive Metrics: Track cost savings from fuel efficiency improvements, potential revenue from green premiums (price increases for low-carbon services), and reduced recruitment costs due to higher employee morale [4][7]. Notably, products marketed as sustainable have shown a 28% cumulative growth over five years compared to 20% for non-sustainable products [7].

Establish a "base case" financial forecast using your historical financial and sustainability data before implementing new strategies [7]. This benchmark will help you determine whether your investments are driving positive returns.

Metric Category | Specific Data Point | Purpose for ROI Baseline |

|---|---|---|

Environmental | Scope 1, 2, & 3 Emissions | Measure total carbon footprint and regulatory exposure [8] |

Environmental | EEOI / AER | Track operational efficiency and fuel-to-cargo ratios [8] |

Financial | Fuel Consumption Costs | Baseline for savings from efficiency or alternative fuels [4] |

Financial | Green Premiums | Identify potential revenue growth from sustainable services [7] |

Financial | Regulatory/Legal Risk | Quantify potential costs of non-compliance or carbon taxes [7] |

These benchmarks serve as the foundation for the next steps, where you'll leverage technology and specialized expertise to optimize operations and enhance sustainability.

Step 2: Implement High-Impact Sustainability Initiatives

Once baseline metrics are established, the next step is to roll out initiatives that cut emissions while delivering measurable cost savings. The focus should be on reducing fuel consumption and operational waste - areas where environmental benefits align directly with financial efficiency.

Improve Fuel Efficiency

Fuel expenses rank among the highest operating costs in maritime operations. Upgrading hardware, such as installing propeller devices, applying high-performance hull coatings, or retrofitting bulbous bows, can yield returns within two years. For instance, one container line successfully reduced fuel consumption by 8% through such measures[1]. Additionally, slowing vessel speeds - known as slow steaming - can cut fuel use by 10% to 15% with just a one-knot reduction. Pairing these efforts with analytics-driven sailing optimization, which considers factors like weather, currents, port readiness, and fuel prices, can further enhance efficiency. Scheduling retrofits during planned dry dock periods and adopting a "Design-to-Value" strategy for new vessel construction can ensure maximum return on investment[1]. These steps lay the groundwork for broader supply chain improvements.

Make Your Supply Chain More Sustainable

In addition to vessel upgrades, refining supply chain processes can lead to significant savings. Consolidating shipments reduces the number of trips required, lowering both per-unit transportation costs and fuel consumption. Cutting back on overpackaging not only saves on materials but also reduces fuel use during transport[6]. For inland logistics, electrification is key - electric vehicles for heavy-duty trucking and last-mile deliveries can cut fuel costs while meeting stricter urban emissions regulations[2]. Warehousing offers opportunities as well: installing solar panels on large rooftops can power lighting and HVAC systems, sometimes even producing surplus energy for the grid. Automated storage and retrieval systems enhance picking accuracy while reducing energy waste[2].

When selecting carriers and logistics partners, prioritize those with verified emissions data and strong efficiency programs, especially those accounting for 75% to 80% of your spending. Frameworks like the EPA's SmartWay program can serve as valuable tools for benchmarking performance without the need to develop internal tracking systems from scratch[4][6].

Step 3: Use Technology and Data to Track ROI

Start leveraging digital tools to measure the operational benefits of recent fuel and supply chain upgrades [11]. Once these enhancements are in place, the focus shifts to determining whether they are delivering the expected returns. Without effective tracking systems, it becomes challenging to assess the value of your sustainability investments or identify areas for further improvement.

Use Data-Driven Tools

Business Intelligence platforms and real-time dashboards are invaluable for connecting operational changes to financial outcomes. These tools consolidate data from systems like Transportation Management, Warehouse Management, and dock scheduling, providing a comprehensive view of performance [11]. Key metrics to monitor include reduced detention fees, improved labor efficiency, and optimized vessel routing [11]. By linking operational changes to measurable financial results, these insights provide a clear picture of your progress.

Before rolling out new digital tools, document baseline metrics to enable clear comparisons between pre- and post-implementation performance [11]. After deployment, calculate time-based savings using actual costs. For instance, if carrier wait times are reduced by 30 minutes per truck across 500 trucks monthly, apply the average hourly cost of trucks and drivers to determine savings [11]. In 2024, A.P. Moller – Maersk expanded its sustainable fleet by introducing seven dual-fuel vessels capable of running on green methanol, alongside the retrofitted Maersk Halifax - the first dual-fuel methanol container vessel in the industry. These efforts align with the company’s goal of achieving net-zero greenhouse gas emissions by 2040 [3]. Pairing these tools with predictive maintenance analysis can uncover even more operational savings [11].

Track Predictive Maintenance Savings

Predictive technologies like digital routing and dock scheduling systems help reduce fuel consumption by incorporating real-time data on variables like weather, currents, and port readiness [11]. These platforms use "Planned vs. Actual" analyses to identify inefficiencies and cut down on idle times for vessels [11]. Meanwhile, automated storage and retrieval systems in warehouses reduce energy usage by operating in the dark and improving picking accuracy [10][2]. To measure the return on investment (ROI) of these technologies, apply the payback period formula: divide the investment cost by the annual benefits [11].

"The ability to accurately measure the Return on Investment (ROI) of a dock scheduling system is no longer a 'nice-to-have'; it's a fundamental component of strategic decision-making." - QueueMe [11]

When calculating ROI, include all associated costs, such as software licenses, implementation, configuration, staff training, and ongoing maintenance. Overlooking these expenses can lead to inflated ROI figures and complicate justifications for future investments [11]. Beyond financial metrics, digital tools can also strengthen carrier relationships and reduce the stress of manual coordination via email and phone [11]. These actionable insights not only reinforce the alignment of sustainability goals with financial returns but also lay the groundwork for scaling these initiatives effectively in future steps.

Step 4: Work with Experts to Implement Your Strategy

Once you’ve established a clear return on investment (ROI) baseline and identified effective sustainability initiatives, it’s time to bring in specialized expertise. Developing a sustainability strategy that delivers measurable results often demands skills and knowledge that many maritime and logistics companies lack internally. While 90% of executives prioritize sustainability, only 60% have formal strategies in place, and nearly half struggle to measure ROI effectively [2][12]. This gap between ambition and execution highlights the importance of expert guidance.

Collaborate with Experts to Create Decarbonization Pathways

Specialized consultants can recommend proven and adaptable measures that yield ROI, regardless of which future fuel becomes dominant [1][13]. For instance, a prominent container shipping company worked closely with technical experts to implement over 400 hardware upgrades across 150 vessels. By optimizing components such as propellers, bulbous bows, and internal boilers, the company successfully reduced total fuel consumption by 8% [1].

Experts also leverage advanced tools like Fleet Decarbonization Optimizers to calculate detailed costs at the vessel level. These tools help pinpoint the most cost-effective strategies, spanning fleet hardware upgrades, fuel choices, and commercial approaches [1]. Moreover, consultants play a key role in navigating complex regulations like the Carbon Intensity Indicator (CII), Energy Efficiency Existing Ship Index (EEXI), and the European Union Emissions Trading System (EU ETS). This guidance is essential, especially considering that roughly 70% of the global tanker and container fleets would have failed to meet 2028 CII requirements based on their 2018 performance [1].

Beyond regulatory compliance, consultants help build comprehensive business cases that go beyond immediate cost reductions. These include cutting waste, capturing "green premiums" to drive revenue, managing risks through compliance, and enhancing brand reputation [12].

"The transition to zero carbon can be a value-generating opportunity for shipping companies - if they are proactive and purposeful, rather than reactive and defensive." – McKinsey Travel, Logistics & Infrastructure Practice [1]

Align Stakeholders for Greater Impact

Sustainability efforts thrive on collaboration, but misaligned priorities often create challenges. In fact, 62% of companies report disagreements between boards and management on sustainability goals [14]. Expert consultants can bridge these gaps by using established frameworks like the Task Force on Climate-Related Financial Disclosures (TCFD), Global Reporting Initiative (GRI), and Science-Based Targets initiative (SBTi). These tools streamline the process of assessing climate risks and tracking progress, eliminating the need to start from scratch [14].

Additionally, consultants help manage pressures from shareholders, regulators, customers, and lenders regarding environmental, social, and governance (ESG) performance. They can also assist in segmenting customers based on their Scope 3 emissions goals, enabling you to prioritize "green" shipping services for those willing to pay a premium for decarbonized solutions [1]. This strategic focus not only transforms sustainability into a competitive advantage but also positions your company to capture market share while others remain mired in indecision. By aligning stakeholders and focusing on measurable outcomes, expert guidance lays the groundwork for scalable and impactful results.

Step 5: Measure Results and Scale What Works

Once sustainability initiatives are in motion, the next step is to evaluate their financial impact and expand successful practices. Companies actively addressing environmental concerns report an average of $1.2 billion in annual savings from emission-reduction projects, with supply chain initiatives typically paying off within three years [15]. The key challenge lies in transitioning from small-scale pilots to comprehensive, organization-wide transformations that yield measurable returns.

Use ROI Frameworks to Show Impact

Traditional accounting often fails to capture the complete financial value of sustainability investments. By adopting impact-weighted accounts, companies can assign monetary value to social, human, and environmental benefits [17]. This method highlights that intangible benefits, such as improved brand reputation and enhanced employee engagement, can be worth 4 to 10 times more than tangible cost savings [17].

The ROSI™ (Return on Sustainability Investment) methodology, developed by NYU Stern Center for Sustainable Business, connects sustainability strategies with financial performance. It aligns ROI metrics with those used by finance teams, going beyond direct cost reductions to include "avoided costs" through risk mitigation, "enabled value" from new revenue sources like green contracts, and "soft benefits" such as higher talent retention [15][17]. For example, maritime companies can track metrics like AER (Annual Efficiency Ratio) and EEOI (Energy Efficiency Operational Indicator) to measure improvements. In 2024, X-Press Feeders achieved a 20.4% year-over-year improvement in EEOI and a 20.0% improvement in AER by deploying dual-fuel vessels powered by green methanol. These results were independently verified by ClassNK [8].

"The green bottom line is a robust, multi-faceted, and compelling financial reality." – RNG Strategy Consulting [15]

These frameworks provide the necessary validation for pilot projects, paving the way for broader implementation.

Expand High-Impact Initiatives

Once pilot projects demonstrate solid ROI, the next step is to scale these initiatives across the organization. Leading shipping companies, for instance, see greater returns by applying energy-saving solutions like hull coatings and propeller upgrades to their entire fleet portfolio, rather than limiting them to individual vessels [18]. For example, propeller ducts can improve efficiency by 2% to 9% over a vessel's lifetime, with a payback period of just three to four years [18]. A major container line reduced fuel consumption by 8% after making over 400 modifications to 150 vessels [1].

Scaling requires efficient processes and robust data systems to ensure consistency [16]. Timing sustainability upgrades with regular operational cycles - such as implementing hardware retrofits during scheduled drydocking - minimizes downtime and reduces costs [1]. For example, a leading consumer packaged goods (CPG) company forecasts annual savings of $200 million and expects to avoid $400 million in cumulative costs by 2030 through improvements in manufacturing and logistics [7].

Adopting a pilot-and-fund model can also be effective, where savings from initial projects finance larger-scale initiatives [15]. For instance, a 3% improvement in On-Time-In-Full delivery, achieved through better supply chain visibility, can boost top-line revenue by 1% [19]. This approach ensures that successful initiatives are not only sustained but also expanded to drive long-term value.

Conclusion: Turn Sustainability into a Competitive Advantage

The maritime and logistics industry stands at a critical crossroads. While many executives recognize the importance of sustainability, few have implemented formal strategies to address it [2]. This gap presents a clear opportunity for companies willing to act with purpose. By prioritizing sustainability, businesses can unlock green premiums, secure alternative fuel sources, and enhance operational resilience.

Key Takeaways for Maritime & Logistics Leaders

To align sustainability with profitability, treat carbon reduction as equally important as efficiency and cost. This approach, often referred to as the "triangle of optimization", ensures that environmental goals complement, rather than compete with, financial objectives [5]. Companies that act early - securing alternative fuel supplies and upgrading hardware during routine maintenance - position themselves as forward-thinking leaders in the green transition. Notably, 85% of shippers are expected to prioritize sustainability when selecting partners [1].

The most effective organizations focus on initiatives with immediate impact and manageable payback periods, such as improving propeller designs and applying advanced hull coatings. Simultaneously, they invest in long-term strategies like green fuel procurement and fleet electrification. Leading companies also engage suppliers strategically, link executive compensation to sustainability performance, and use data-driven tools to pinpoint investments with the highest net present value. McKinsey highlights this proactive approach:

"The transition to zero carbon can be a value-generating opportunity for shipping companies - if they are proactive and purposeful, rather than reactive and defensive" [1].

These practices provide a clear framework for taking meaningful action.

Next Steps to Put Your Strategy into Action

Start by establishing a clear baseline for your current emissions and operational costs. Focus on the 75% to 80% of suppliers that account for the majority of your spending or reputational exposure, and launch targeted engagement programs [4]. Pilot impactful initiatives like speed optimization and fuel-efficient hardware upgrades, rigorously measure their financial returns, and expand successful efforts across your entire fleet. By taking these steps, companies can transform sustainability from a challenge into a competitive edge.

FAQs

How can maritime companies measure their carbon footprint and assess the ROI of sustainability efforts?

To gauge their carbon footprint, maritime companies should begin with standardized frameworks and robust data collection practices. This means monitoring factors like fuel consumption, engine efficiency, and voyage-specific metrics, then applying emission factors to calculate CO₂e emissions per nautical mile or per unit of cargo transported. Leveraging digital tools that provide real-time insights into fuel usage and vessel performance can significantly improve the precision of these calculations.

When evaluating return on investment (ROI), companies can tie emission reductions directly to cost savings, especially through decreased fuel usage. Cutting CO₂ emissions often translates into lower fuel expenses, offering immediate financial benefits. Beyond cost savings, sustainability efforts can deliver strategic advantages, such as appealing to customers who prioritize low-carbon shipping options, earning regulatory incentives, or commanding higher prices for environmentally conscious services. By integrating precise emissions tracking with a thorough analysis of cost efficiencies and revenue opportunities, maritime companies can effectively showcase the economic benefits of their green initiatives.

What are the most effective ways for maritime logistics companies to reduce emissions while improving ROI?

Reducing emissions in maritime logistics involves a mix of technological advancements, fuel alternatives, and operational improvements, which can also yield measurable financial returns.

Implementing practices such as slow steaming, hull cleaning, propeller upgrades, and advanced weather routing can cut fuel consumption by 5-15% per voyage. These measures not only lower emissions but also reduce operating costs. Transitioning to low-carbon fuels like LNG, green ammonia, or biofuels, alongside integrating wind-assisted propulsion systems such as retrofitted sails, further reduces carbon footprints while supporting long-term sustainability goals.

Another impactful strategy is the use of shore-side electricity (cold ironing) at ports, which eliminates emissions during docking. Meanwhile, digital tools for emissions monitoring provide real-time data, allowing companies to track progress and optimize operations. By adopting these approaches, maritime logistics firms can significantly cut greenhouse gas emissions, boost profitability, and contribute to global sustainability objectives, benefiting both the industry and its stakeholders.

How can logistics companies use technology to track and improve the ROI of sustainability efforts?

Technology is empowering logistics companies to transform sustainability efforts into measurable financial benefits through real-time data, analytics, and automation. Take dock-scheduling platforms, for instance - they provide insights into metrics like berth utilization, idling times, and fuel consumption. By improving scheduling, companies can cut costs tied to fuel usage, overtime pay, and equipment wear. These measurable outcomes can be directly linked to ROI calculations, making the financial benefits of sustainability initiatives more transparent.

Advanced tools such as IoT sensors, AI-driven route optimization, and digital simulations further enhance efficiency. IoT devices monitor fuel consumption and engine performance, while AI evaluates optimal routes or alternative fuel options to minimize emissions. The data generated by these technologies not only highlights cost savings but also helps businesses benchmark their performance against industry standards.

When these systems are integrated into a unified platform, companies gain the ability to continuously track emissions reductions, fuel savings, and operational improvements. This creates a feedback loop where every action is measured, its financial return is quantified, and the insights guide future strategies. This approach ensures sustainability efforts not only support environmental goals but also drive profitability and strengthen stakeholder value.

Related Blog Posts

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Dec 31, 2025

How to Build a Corporate Sustainability Strategy Aligned to ROI for Maritime & Logistics Companies

Sustainability Strategy

In This Article

Align maritime and logistics sustainability with ROI: measure Scope 1–3, prioritize fuel efficiency and tech, engage experts, and scale proven pilots.

How to Build a Corporate Sustainability Strategy Aligned to ROI for Maritime & Logistics Companies

The maritime and logistics industry, responsible for 90% of global trade, contributes 3% of global greenhouse gas emissions. With stricter regulations, customer demands, and financial pressures, sustainability is no longer optional. Companies must align sustainability efforts with financial returns to stay competitive.

Key Takeaways:

Regulatory Compliance: The IMO aims for net-zero emissions by 2050, with regional policies enforcing stricter standards.

Customer Demands: Major cargo owners like Amazon and Ikea push for zero-carbon shipping by 2040.

Financial Opportunities: Over 50% of consumers are willing to pay premiums for sustainable shipping, and fuel efficiency upgrades can pay off within two years.

Steps to Build a Strategy:

Evaluate Current Operations: Measure emissions (Scope 1, 2, 3) and establish financial baselines.

Implement Fuel-Efficiency Initiatives: Use hardware upgrades, slow steaming, and supply chain optimizations.

Leverage Technology: Deploy tools to track ROI and improve decision-making.

Engage Experts: Collaborate with specialists for decarbonization pathways and regulatory compliance.

Scale Effective Initiatives: Expand successful pilots across fleets or supply chains for broader impact.

By integrating measurable goals and focusing on cost-effective solutions, maritime and logistics companies can align environmental goals with profitability.

5-Step Corporate Sustainability Strategy for Maritime & Logistics Companies

Building an Actionable Maritime Decarbonization Strategy with Berge Bulk and Sofar Ocean

Step 1: Evaluate Current Operations and Set ROI Baselines

Before diving into new initiatives, it's essential to understand where you currently stand. Begin by assessing your environmental impact and establishing clear financial benchmarks. These baselines are your starting point for tracking improvements and determining whether your investments deliver measurable returns. Start by quantifying both your carbon footprint and financial exposure.

Measure Your Carbon Footprint

To calculate your emissions effectively, use the GHG Protocol Standard [9], which divides emissions into three categories, or "scopes":

Scope 1: Direct emissions from assets you own or operate, such as vessel fuel use and refrigerants [8].

Scope 2: Indirect emissions from purchased electricity for offices, warehouses, and port terminals [8].

Scope 3: Often the largest category for maritime companies, covering emissions from upstream fuel production, purchased goods, employee travel, and outsourced transportation [9][8].

For maritime operations, it's also crucial to track intensity metrics like the Energy Efficiency Operational Indicator (EEOI) and the Annual Efficiency Ratio (AER). These metrics measure carbon intensity per unit of work, such as grams of CO₂ per ton-mile, providing insights into operational efficiency [8]. For example, in 2024, X-Press Feeders achieved an EEOI of 20.430 gCO₂e/MT-Nm, reflecting a 20.4% improvement from the previous year. Their AER for owned vessels improved by 20.0% year-over-year, reaching 10.358 gCO₂/DWT-Nm. Both metrics were independently verified by ClassNK [8].

When addressing Scope 3 emissions, prioritize suppliers that account for 75% to 80% of your spending or those with energy-intensive activities [4]. For smaller supply chain partners, simplify the data collection process with tools like the EPA's Simplified GHG Emissions Calculator or straightforward questionnaires to encourage high response rates [4].

By integrating these environmental metrics with financial data, you’ll establish a robust ROI baseline that aligns operational performance with sustainability goals.

Select Key ROI Metrics

To evaluate the financial impact of your sustainability efforts, incorporate both defensive and offensive ROI metrics into your baseline:

Defensive Metrics: Quantify risks such as regulatory fines, carbon taxes, and potential market share losses. For example, in heavily regulated industries, non-compliance fines can reduce EBITDA by an average of 0.75% over a decade [7].

Offensive Metrics: Track cost savings from fuel efficiency improvements, potential revenue from green premiums (price increases for low-carbon services), and reduced recruitment costs due to higher employee morale [4][7]. Notably, products marketed as sustainable have shown a 28% cumulative growth over five years compared to 20% for non-sustainable products [7].

Establish a "base case" financial forecast using your historical financial and sustainability data before implementing new strategies [7]. This benchmark will help you determine whether your investments are driving positive returns.

Metric Category | Specific Data Point | Purpose for ROI Baseline |

|---|---|---|

Environmental | Scope 1, 2, & 3 Emissions | Measure total carbon footprint and regulatory exposure [8] |

Environmental | EEOI / AER | Track operational efficiency and fuel-to-cargo ratios [8] |

Financial | Fuel Consumption Costs | Baseline for savings from efficiency or alternative fuels [4] |

Financial | Green Premiums | Identify potential revenue growth from sustainable services [7] |

Financial | Regulatory/Legal Risk | Quantify potential costs of non-compliance or carbon taxes [7] |

These benchmarks serve as the foundation for the next steps, where you'll leverage technology and specialized expertise to optimize operations and enhance sustainability.

Step 2: Implement High-Impact Sustainability Initiatives

Once baseline metrics are established, the next step is to roll out initiatives that cut emissions while delivering measurable cost savings. The focus should be on reducing fuel consumption and operational waste - areas where environmental benefits align directly with financial efficiency.

Improve Fuel Efficiency

Fuel expenses rank among the highest operating costs in maritime operations. Upgrading hardware, such as installing propeller devices, applying high-performance hull coatings, or retrofitting bulbous bows, can yield returns within two years. For instance, one container line successfully reduced fuel consumption by 8% through such measures[1]. Additionally, slowing vessel speeds - known as slow steaming - can cut fuel use by 10% to 15% with just a one-knot reduction. Pairing these efforts with analytics-driven sailing optimization, which considers factors like weather, currents, port readiness, and fuel prices, can further enhance efficiency. Scheduling retrofits during planned dry dock periods and adopting a "Design-to-Value" strategy for new vessel construction can ensure maximum return on investment[1]. These steps lay the groundwork for broader supply chain improvements.

Make Your Supply Chain More Sustainable

In addition to vessel upgrades, refining supply chain processes can lead to significant savings. Consolidating shipments reduces the number of trips required, lowering both per-unit transportation costs and fuel consumption. Cutting back on overpackaging not only saves on materials but also reduces fuel use during transport[6]. For inland logistics, electrification is key - electric vehicles for heavy-duty trucking and last-mile deliveries can cut fuel costs while meeting stricter urban emissions regulations[2]. Warehousing offers opportunities as well: installing solar panels on large rooftops can power lighting and HVAC systems, sometimes even producing surplus energy for the grid. Automated storage and retrieval systems enhance picking accuracy while reducing energy waste[2].

When selecting carriers and logistics partners, prioritize those with verified emissions data and strong efficiency programs, especially those accounting for 75% to 80% of your spending. Frameworks like the EPA's SmartWay program can serve as valuable tools for benchmarking performance without the need to develop internal tracking systems from scratch[4][6].

Step 3: Use Technology and Data to Track ROI

Start leveraging digital tools to measure the operational benefits of recent fuel and supply chain upgrades [11]. Once these enhancements are in place, the focus shifts to determining whether they are delivering the expected returns. Without effective tracking systems, it becomes challenging to assess the value of your sustainability investments or identify areas for further improvement.

Use Data-Driven Tools

Business Intelligence platforms and real-time dashboards are invaluable for connecting operational changes to financial outcomes. These tools consolidate data from systems like Transportation Management, Warehouse Management, and dock scheduling, providing a comprehensive view of performance [11]. Key metrics to monitor include reduced detention fees, improved labor efficiency, and optimized vessel routing [11]. By linking operational changes to measurable financial results, these insights provide a clear picture of your progress.

Before rolling out new digital tools, document baseline metrics to enable clear comparisons between pre- and post-implementation performance [11]. After deployment, calculate time-based savings using actual costs. For instance, if carrier wait times are reduced by 30 minutes per truck across 500 trucks monthly, apply the average hourly cost of trucks and drivers to determine savings [11]. In 2024, A.P. Moller – Maersk expanded its sustainable fleet by introducing seven dual-fuel vessels capable of running on green methanol, alongside the retrofitted Maersk Halifax - the first dual-fuel methanol container vessel in the industry. These efforts align with the company’s goal of achieving net-zero greenhouse gas emissions by 2040 [3]. Pairing these tools with predictive maintenance analysis can uncover even more operational savings [11].

Track Predictive Maintenance Savings

Predictive technologies like digital routing and dock scheduling systems help reduce fuel consumption by incorporating real-time data on variables like weather, currents, and port readiness [11]. These platforms use "Planned vs. Actual" analyses to identify inefficiencies and cut down on idle times for vessels [11]. Meanwhile, automated storage and retrieval systems in warehouses reduce energy usage by operating in the dark and improving picking accuracy [10][2]. To measure the return on investment (ROI) of these technologies, apply the payback period formula: divide the investment cost by the annual benefits [11].

"The ability to accurately measure the Return on Investment (ROI) of a dock scheduling system is no longer a 'nice-to-have'; it's a fundamental component of strategic decision-making." - QueueMe [11]

When calculating ROI, include all associated costs, such as software licenses, implementation, configuration, staff training, and ongoing maintenance. Overlooking these expenses can lead to inflated ROI figures and complicate justifications for future investments [11]. Beyond financial metrics, digital tools can also strengthen carrier relationships and reduce the stress of manual coordination via email and phone [11]. These actionable insights not only reinforce the alignment of sustainability goals with financial returns but also lay the groundwork for scaling these initiatives effectively in future steps.

Step 4: Work with Experts to Implement Your Strategy

Once you’ve established a clear return on investment (ROI) baseline and identified effective sustainability initiatives, it’s time to bring in specialized expertise. Developing a sustainability strategy that delivers measurable results often demands skills and knowledge that many maritime and logistics companies lack internally. While 90% of executives prioritize sustainability, only 60% have formal strategies in place, and nearly half struggle to measure ROI effectively [2][12]. This gap between ambition and execution highlights the importance of expert guidance.

Collaborate with Experts to Create Decarbonization Pathways

Specialized consultants can recommend proven and adaptable measures that yield ROI, regardless of which future fuel becomes dominant [1][13]. For instance, a prominent container shipping company worked closely with technical experts to implement over 400 hardware upgrades across 150 vessels. By optimizing components such as propellers, bulbous bows, and internal boilers, the company successfully reduced total fuel consumption by 8% [1].

Experts also leverage advanced tools like Fleet Decarbonization Optimizers to calculate detailed costs at the vessel level. These tools help pinpoint the most cost-effective strategies, spanning fleet hardware upgrades, fuel choices, and commercial approaches [1]. Moreover, consultants play a key role in navigating complex regulations like the Carbon Intensity Indicator (CII), Energy Efficiency Existing Ship Index (EEXI), and the European Union Emissions Trading System (EU ETS). This guidance is essential, especially considering that roughly 70% of the global tanker and container fleets would have failed to meet 2028 CII requirements based on their 2018 performance [1].

Beyond regulatory compliance, consultants help build comprehensive business cases that go beyond immediate cost reductions. These include cutting waste, capturing "green premiums" to drive revenue, managing risks through compliance, and enhancing brand reputation [12].

"The transition to zero carbon can be a value-generating opportunity for shipping companies - if they are proactive and purposeful, rather than reactive and defensive." – McKinsey Travel, Logistics & Infrastructure Practice [1]

Align Stakeholders for Greater Impact

Sustainability efforts thrive on collaboration, but misaligned priorities often create challenges. In fact, 62% of companies report disagreements between boards and management on sustainability goals [14]. Expert consultants can bridge these gaps by using established frameworks like the Task Force on Climate-Related Financial Disclosures (TCFD), Global Reporting Initiative (GRI), and Science-Based Targets initiative (SBTi). These tools streamline the process of assessing climate risks and tracking progress, eliminating the need to start from scratch [14].

Additionally, consultants help manage pressures from shareholders, regulators, customers, and lenders regarding environmental, social, and governance (ESG) performance. They can also assist in segmenting customers based on their Scope 3 emissions goals, enabling you to prioritize "green" shipping services for those willing to pay a premium for decarbonized solutions [1]. This strategic focus not only transforms sustainability into a competitive advantage but also positions your company to capture market share while others remain mired in indecision. By aligning stakeholders and focusing on measurable outcomes, expert guidance lays the groundwork for scalable and impactful results.

Step 5: Measure Results and Scale What Works

Once sustainability initiatives are in motion, the next step is to evaluate their financial impact and expand successful practices. Companies actively addressing environmental concerns report an average of $1.2 billion in annual savings from emission-reduction projects, with supply chain initiatives typically paying off within three years [15]. The key challenge lies in transitioning from small-scale pilots to comprehensive, organization-wide transformations that yield measurable returns.

Use ROI Frameworks to Show Impact

Traditional accounting often fails to capture the complete financial value of sustainability investments. By adopting impact-weighted accounts, companies can assign monetary value to social, human, and environmental benefits [17]. This method highlights that intangible benefits, such as improved brand reputation and enhanced employee engagement, can be worth 4 to 10 times more than tangible cost savings [17].

The ROSI™ (Return on Sustainability Investment) methodology, developed by NYU Stern Center for Sustainable Business, connects sustainability strategies with financial performance. It aligns ROI metrics with those used by finance teams, going beyond direct cost reductions to include "avoided costs" through risk mitigation, "enabled value" from new revenue sources like green contracts, and "soft benefits" such as higher talent retention [15][17]. For example, maritime companies can track metrics like AER (Annual Efficiency Ratio) and EEOI (Energy Efficiency Operational Indicator) to measure improvements. In 2024, X-Press Feeders achieved a 20.4% year-over-year improvement in EEOI and a 20.0% improvement in AER by deploying dual-fuel vessels powered by green methanol. These results were independently verified by ClassNK [8].

"The green bottom line is a robust, multi-faceted, and compelling financial reality." – RNG Strategy Consulting [15]

These frameworks provide the necessary validation for pilot projects, paving the way for broader implementation.

Expand High-Impact Initiatives

Once pilot projects demonstrate solid ROI, the next step is to scale these initiatives across the organization. Leading shipping companies, for instance, see greater returns by applying energy-saving solutions like hull coatings and propeller upgrades to their entire fleet portfolio, rather than limiting them to individual vessels [18]. For example, propeller ducts can improve efficiency by 2% to 9% over a vessel's lifetime, with a payback period of just three to four years [18]. A major container line reduced fuel consumption by 8% after making over 400 modifications to 150 vessels [1].

Scaling requires efficient processes and robust data systems to ensure consistency [16]. Timing sustainability upgrades with regular operational cycles - such as implementing hardware retrofits during scheduled drydocking - minimizes downtime and reduces costs [1]. For example, a leading consumer packaged goods (CPG) company forecasts annual savings of $200 million and expects to avoid $400 million in cumulative costs by 2030 through improvements in manufacturing and logistics [7].

Adopting a pilot-and-fund model can also be effective, where savings from initial projects finance larger-scale initiatives [15]. For instance, a 3% improvement in On-Time-In-Full delivery, achieved through better supply chain visibility, can boost top-line revenue by 1% [19]. This approach ensures that successful initiatives are not only sustained but also expanded to drive long-term value.

Conclusion: Turn Sustainability into a Competitive Advantage

The maritime and logistics industry stands at a critical crossroads. While many executives recognize the importance of sustainability, few have implemented formal strategies to address it [2]. This gap presents a clear opportunity for companies willing to act with purpose. By prioritizing sustainability, businesses can unlock green premiums, secure alternative fuel sources, and enhance operational resilience.

Key Takeaways for Maritime & Logistics Leaders

To align sustainability with profitability, treat carbon reduction as equally important as efficiency and cost. This approach, often referred to as the "triangle of optimization", ensures that environmental goals complement, rather than compete with, financial objectives [5]. Companies that act early - securing alternative fuel supplies and upgrading hardware during routine maintenance - position themselves as forward-thinking leaders in the green transition. Notably, 85% of shippers are expected to prioritize sustainability when selecting partners [1].

The most effective organizations focus on initiatives with immediate impact and manageable payback periods, such as improving propeller designs and applying advanced hull coatings. Simultaneously, they invest in long-term strategies like green fuel procurement and fleet electrification. Leading companies also engage suppliers strategically, link executive compensation to sustainability performance, and use data-driven tools to pinpoint investments with the highest net present value. McKinsey highlights this proactive approach:

"The transition to zero carbon can be a value-generating opportunity for shipping companies - if they are proactive and purposeful, rather than reactive and defensive" [1].

These practices provide a clear framework for taking meaningful action.

Next Steps to Put Your Strategy into Action

Start by establishing a clear baseline for your current emissions and operational costs. Focus on the 75% to 80% of suppliers that account for the majority of your spending or reputational exposure, and launch targeted engagement programs [4]. Pilot impactful initiatives like speed optimization and fuel-efficient hardware upgrades, rigorously measure their financial returns, and expand successful efforts across your entire fleet. By taking these steps, companies can transform sustainability from a challenge into a competitive edge.

FAQs

How can maritime companies measure their carbon footprint and assess the ROI of sustainability efforts?

To gauge their carbon footprint, maritime companies should begin with standardized frameworks and robust data collection practices. This means monitoring factors like fuel consumption, engine efficiency, and voyage-specific metrics, then applying emission factors to calculate CO₂e emissions per nautical mile or per unit of cargo transported. Leveraging digital tools that provide real-time insights into fuel usage and vessel performance can significantly improve the precision of these calculations.

When evaluating return on investment (ROI), companies can tie emission reductions directly to cost savings, especially through decreased fuel usage. Cutting CO₂ emissions often translates into lower fuel expenses, offering immediate financial benefits. Beyond cost savings, sustainability efforts can deliver strategic advantages, such as appealing to customers who prioritize low-carbon shipping options, earning regulatory incentives, or commanding higher prices for environmentally conscious services. By integrating precise emissions tracking with a thorough analysis of cost efficiencies and revenue opportunities, maritime companies can effectively showcase the economic benefits of their green initiatives.

What are the most effective ways for maritime logistics companies to reduce emissions while improving ROI?

Reducing emissions in maritime logistics involves a mix of technological advancements, fuel alternatives, and operational improvements, which can also yield measurable financial returns.

Implementing practices such as slow steaming, hull cleaning, propeller upgrades, and advanced weather routing can cut fuel consumption by 5-15% per voyage. These measures not only lower emissions but also reduce operating costs. Transitioning to low-carbon fuels like LNG, green ammonia, or biofuels, alongside integrating wind-assisted propulsion systems such as retrofitted sails, further reduces carbon footprints while supporting long-term sustainability goals.

Another impactful strategy is the use of shore-side electricity (cold ironing) at ports, which eliminates emissions during docking. Meanwhile, digital tools for emissions monitoring provide real-time data, allowing companies to track progress and optimize operations. By adopting these approaches, maritime logistics firms can significantly cut greenhouse gas emissions, boost profitability, and contribute to global sustainability objectives, benefiting both the industry and its stakeholders.

How can logistics companies use technology to track and improve the ROI of sustainability efforts?

Technology is empowering logistics companies to transform sustainability efforts into measurable financial benefits through real-time data, analytics, and automation. Take dock-scheduling platforms, for instance - they provide insights into metrics like berth utilization, idling times, and fuel consumption. By improving scheduling, companies can cut costs tied to fuel usage, overtime pay, and equipment wear. These measurable outcomes can be directly linked to ROI calculations, making the financial benefits of sustainability initiatives more transparent.

Advanced tools such as IoT sensors, AI-driven route optimization, and digital simulations further enhance efficiency. IoT devices monitor fuel consumption and engine performance, while AI evaluates optimal routes or alternative fuel options to minimize emissions. The data generated by these technologies not only highlights cost savings but also helps businesses benchmark their performance against industry standards.

When these systems are integrated into a unified platform, companies gain the ability to continuously track emissions reductions, fuel savings, and operational improvements. This creates a feedback loop where every action is measured, its financial return is quantified, and the insights guide future strategies. This approach ensures sustainability efforts not only support environmental goals but also drive profitability and strengthen stakeholder value.

Related Blog Posts

FAQ

What does it really mean to “redefine profit”?

What makes Council Fire different?

Who does Council Fire you work with?

What does working with Council Fire actually look like?

How does Council Fire help organizations turn big goals into action?

How does Council Fire define and measure success?