Sep 23, 2025

Sep 23, 2025

Traceability Metrics Checklist for Value Chains

Sustainability Strategy

Sustainability Strategy

In This Article

Explore essential traceability metrics like Lot IDs and CTEs to enhance supply chain transparency, compliance, and quality management.

Traceability Metrics Checklist for Value Chains

Traceability metrics ensure products are tracked throughout the supply chain, helping businesses meet regulations, address quality concerns, and build trust. This guide explains four key metrics - Lot IDs, Critical Tracking Events (CTEs), Key Data Elements (KDEs), and Data Sharing Standards - and provides a checklist for implementing traceability systems effectively. By integrating technologies like blockchain and IoT, and fostering collaboration among supply chain partners, organizations can improve data accuracy, respond to issues faster, and enhance supply chain transparency.

Key points:

Lot IDs: Unique codes for product batches, ensuring traceability across the chain.

CTEs: Key moments in the product journey, such as production and shipping, recorded for accountability.

KDEs: Essential data like timestamps, quality tests, and environmental conditions.

Data Sharing Standards: Uniform formats (e.g., EDI, EPCIS) for seamless communication.

A successful traceability system requires mapping product flows, aligning stakeholders, and ensuring system interoperability. Regular performance reviews focus on data accuracy, accessibility, cost efficiency, and system reliability. Use this checklist to build a transparent and reliable supply chain.

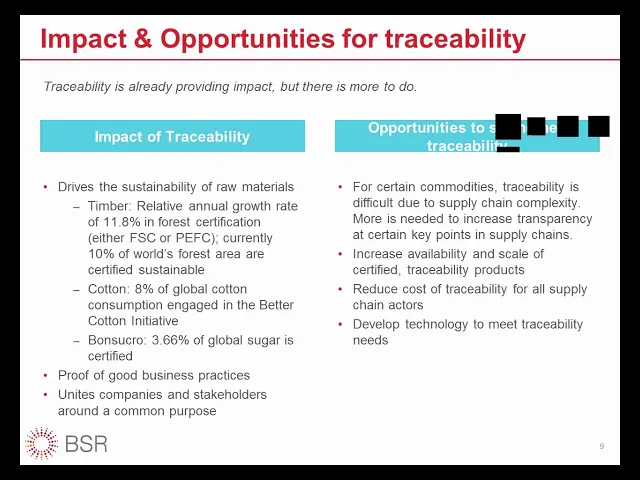

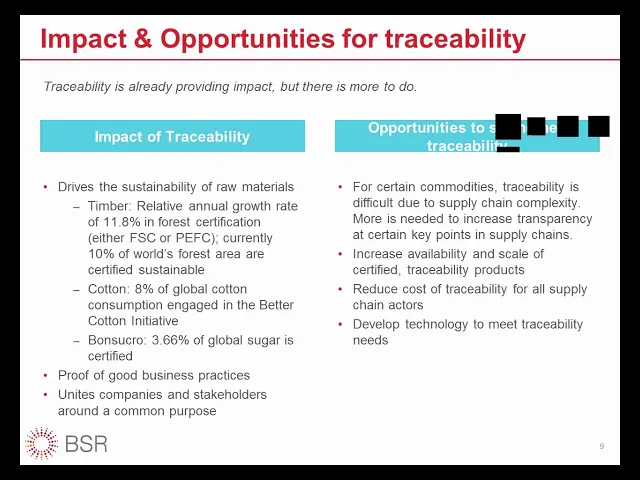

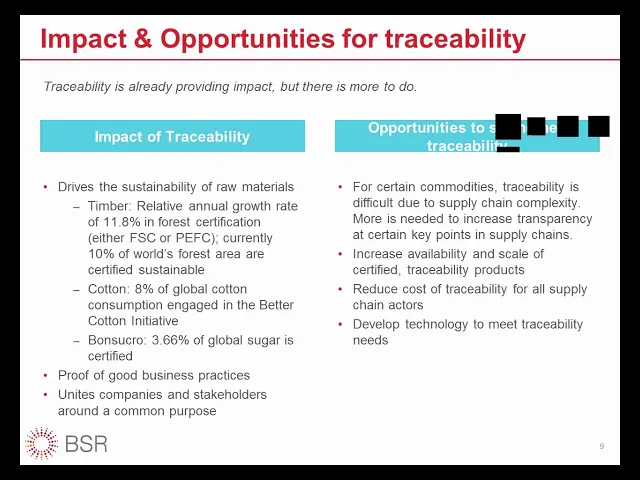

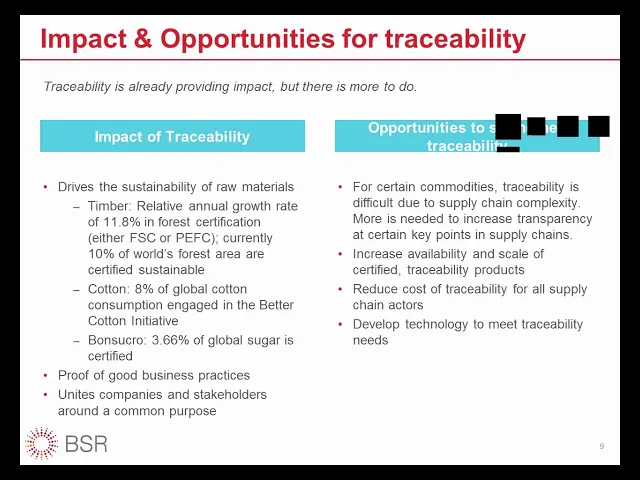

A Guide to Traceability: A Practical Approach to Advance Sustainability in Global Supply Chains

Key Traceability Metrics for Value Chains

Traceability hinges on four essential metrics that enable tracking products from their origin to the consumer. Below, we break down each metric and explain how they fit into a robust traceability system.

Lot Identification Codes (Lot IDs)

Lot IDs act as unique markers for batches, shipments, or production runs within your value chain. These identifiers encapsulate critical details like origin, production date, and handling information.

A well-structured Lot ID typically includes components such as date codes, facility identifiers, and sequential batch numbers. For instance, a code like "ABC-240915-001" might signify products from facility ABC, created on September 15, 2024, as part of the first batch that day.

Standardization is key for Lot IDs to work effectively. When suppliers, manufacturers, distributors, and retailers adopt compatible systems, products can be traced seamlessly across the entire chain. This alignment is crucial for ensuring traceability, especially during recalls or quality checks, as it eliminates gaps in information.

Critical Tracking Events (CTEs)

CTEs pinpoint the key moments when products are transferred, altered, or relocated within the value chain. These events serve as checkpoints, documenting what happened to a product and when. Key CTEs include receiving raw materials, starting production, completing manufacturing, shipping finished goods, and transferring custody between partners.

Transformation events deserve special focus. These are the points where raw materials turn into finished goods or where products are modified, combined, or separated. At these stages, new Lot IDs may be generated while maintaining links to the original materials, creating a detailed product genealogy.

To reduce errors, record CTEs in real time using automated tools like barcode scanners, RFID systems, or IoT-enabled sensors.

Key Data Elements (KDEs)

KDEs capture essential information such as product descriptions, quantities, timestamps, locations, temperature logs, and quality test results. These data points form the backbone of a traceability system.

Environmental conditions are especially critical in industries like food and pharmaceuticals. Monitoring factors like temperature, humidity, and storage conditions ensures product quality and compliance with regulatory standards. For instance, cold chain products - like vaccines or fresh produce - require continuous tracking of temperature to maintain safety and effectiveness.

Quality testing results also play a vital role. Data from inspections, lab tests, and certifications provide evidence of product safety and compliance. These records are indispensable during audits or quality investigations.

Data Sharing Standards

Uniform standards, such as EDI for business transactions and EPCIS for event data, are essential for seamless data exchange across the supply chain.

EDI (Electronic Data Interchange) ensures that business documents like purchase orders, shipping notices, and invoices are formatted consistently. This standardization enables automated processing, reducing manual errors and speeding up communication between partners.

EPCIS (Electronic Product Code Information Services) offers a framework for sharing supply chain event data in a standardized format. It allows companies to communicate details about what happened to products, when and where events took place, and the reasons behind specific actions. By creating a universal "language", EPCIS facilitates visibility across industries and platforms.

These metrics form the foundation of a cohesive traceability system. Mastering them is essential for building and evaluating an effective approach to product tracking, which will be explored further in the next section.

How to Build a Traceability System

Creating a reliable traceability system demands a structured approach that tackles both technical hurdles and organizational complexities. This involves three key components working together to establish a seamless tracking framework across your entire value chain.

Process Flow Mapping

Begin by visually mapping how products move through your value chain. This step involves charting every stage, from sourcing raw materials to delivering the final product. The map should highlight where products are received, processed, stored, and shipped, pinpointing the exact points where traceability data needs to be captured.

Focus on transformation points - where products are altered or combined with other materials. These are critical spots requiring new Lot IDs while maintaining links to the original source materials. This step lays the groundwork for engaging stakeholders and integrating the necessary technology to achieve end-to-end traceability.

Map both product and data flows simultaneously. This dual perspective helps identify potential gaps where information could be lost or where manual processes might introduce errors. Pay particular attention to handoff points between organizations, as these transitions often pose the highest risk for data inconsistencies.

For temperature-sensitive items, such as cold chain products, additional mapping is essential. Continuous monitoring is crucial at key points like loading docks, transportation vehicles, and storage facilities where temperature fluctuations are most likely to occur.

Stakeholder Collaboration

Once the process flow is mapped, it's essential to align all stakeholders to ensure consistent data collection and sharing. Involve every participant in the value chain - suppliers, manufacturers, distributors, retailers, and logistics providers - from the very beginning. Their active participation is vital for the system's success.

Set clear data-sharing agreements that outline what information needs to be collected, its format, and when it should be transmitted. These agreements should also address how to handle data corrections, updates, and system downtimes or failures.

Recognize that technological capabilities will vary across your network. Larger manufacturers may use advanced ERP systems and automated tools, while smaller suppliers might rely on manual methods or basic software. Your traceability system must accommodate this diversity while ensuring the integrity and consistency of the data.

Training and ongoing support are crucial. Stakeholders need to understand not only how to use the system but also why traceability is important for the entire value chain. Regular workshops and continuous technical assistance can help maintain data quality and encourage widespread adoption.

Organizations such as Council Fire often highlight that collaboration in traceability systems can deliver benefits beyond compliance. When thoughtfully implemented, these systems can enhance transparency, strengthen relationships, and support broader social and environmental goals throughout the supply chain.

Technical and System Interoperability

Building on stakeholder collaboration, the next step is to integrate your traceability system with existing tools to ensure a smooth flow of data. Focus on integrating with current software systems like ERP platforms, warehouse management tools, and quality control systems that already house valuable traceability data. Instead of replacing these systems, establish connections that enable automatic data sharing.

Leverage API-based integrations to link systems. This reduces the need for manual data entry and ensures that traceability information remains accurate and up-to-date.

Cloud-based solutions often offer better compatibility than on-premise systems, especially when working with multiple stakeholders using varied software platforms. Cloud systems can more easily support data-sharing standards like EDI and EPCIS while scaling to handle fluctuating data volumes.

Incorporate mobile-friendly tools and strong error-checking mechanisms to capture and validate critical data. Early error detection prevents inaccuracies from spreading through the value chain.

Finally, plan for system redundancy and backup procedures to keep traceability data accessible during technical disruptions. This is especially critical in regulated industries where access to traceability records is mandatory for audits or recall scenarios requiring immediate retrieval of historical data. These measures ensure the system remains reliable and robust under all conditions.

How to Measure Traceability Performance

Once your traceability system is up and running, the next step is to evaluate how well it performs. This process ensures that the system not only functions as intended but also delivers reliable, actionable information for stakeholders. Effective measurement goes beyond simply confirming the presence of data - it focuses on whether the system provides accurate, accessible insights that enable better decision-making.

Accuracy and Completeness of Data

To ensure data accuracy, it’s critical to consistently capture Lot IDs and document each Critical Tracking Event (CTE) with precise details, such as timestamps, locations, and the responsible parties. Missing or incomplete CTE data can cause delays in corrective actions, potentially leading to larger issues.

Key Data Elements (KDEs), like temperature and quality metrics, should follow standardized units and formats to avoid confusion. For example, if suppliers report temperatures in varying units, establish a common standard (e.g., °F) or clearly indicate the unit being used. Regular validation checks should be implemented to catch errors early, preventing them from spreading through the system.

Transparency and Accessibility

A well-functioning traceability system ensures fast, secure, and comprehensive access to data. According to research from MIT Sloan School of Management, consumers are willing to pay 2% to 10% more for products with greater supply chain transparency [1]. To measure this aspect, assess response times for traceability queries across different user groups. For instance, internal quality teams might need immediate access, while external auditors may require detailed reports within specific timeframes.

Tailor data formats to meet the unique needs of various stakeholders. Retailers may only need basic origin information for consumer labels, whereas regulatory agencies might require detailed processing records. Sharing information in a secure and accessible way builds trust across the supply chain.

It’s also important to track how often stakeholders use the system. Monitoring adoption rates can highlight usability issues or indicate where additional training is needed. Once data accuracy and accessibility are ensured, focus shifts to evaluating the system’s cost and efficiency.

Cost and Efficiency

Assessing cost-effectiveness involves tracking the total system costs per unit and comparing them with the benefits, such as reduced recall expenses and quicker issue resolution.

Time efficiency is another key metric. Monitor how long it takes to handle traceability-related tasks, like responding to customer inquiries about product origins, generating regulatory reports, or conducting internal quality investigations. A well-designed system should simplify these processes without sacrificing accuracy.

Pay special attention to the financial impact on smaller suppliers within your value chain. These suppliers may face challenges due to limited technical resources, which can hinder their ability to comply with traceability requirements. Identifying and addressing these barriers - whether through technical support or simplified processes - can improve system performance.

Lastly, track the return on investment by documenting measurable benefits. This could include reduced recall costs, faster problem resolution, improved customer satisfaction, or a stronger brand reputation. Highlight specific cases where traceability data helped resolve issues quickly to justify continued investment. Additionally, monitor system performance during peak periods to identify and address capacity constraints before they affect data quality or accessibility.

Traceability Metrics Checklist Table

This checklist serves as a practical tool for assessing traceability performance and identifying areas for improvement. By turning theoretical concepts into measurable actions, it ensures a more transparent and efficient value chain.

Metric Category | Specific Metric | Application Stage | Performance Criteria | Evaluation Method |

|---|---|---|---|---|

Data Identification | Lot ID Accuracy | Product creation, processing, distribution | 99.5% accuracy rate with zero duplicate IDs | Monthly audit of ID generation systems |

Data Identification | Lot ID Completeness | All value chain stages | 100% of products have assigned IDs | Weekly sampling checks across production lines |

Critical Tracking Events | CTE Documentation | Manufacturing, packaging, shipping | All events recorded within 2 hours of occurrence | Real-time monitoring dashboards |

Critical Tracking Events | Timestamp Precision | All operational stages | Accurate to within 5 minutes of actual event | Cross-reference with production logs |

Key Data Elements | Temperature Recording | Cold chain segments | Continuous monitoring with ±1°F accuracy | Automated sensor checks |

Key Data Elements | Quality Metrics | Inspection points, final packaging | 100% compliance with predefined standards | Statistical process control charts |

Data Sharing | Information Exchange Speed | Inter-company communications | Response time under 4 business hours | Response time tracking system |

Data Sharing | Format Standardization | All external communications | 100% compliance with agreed data formats | Automated format validation checks |

System Performance | Query Response Time | Daily operations | Average response under 30 seconds | System performance monitoring |

System Performance | Data Retrieval Success Rate | Traceability investigations | 99.8% successful data retrieval | Monthly system reliability reports |

Cost Efficiency | System Cost Per Unit | Ongoing operations | Decreasing trend year-over-year | Quarterly cost analysis |

Cost Efficiency | ROI Measurement | Annual assessment | Positive ROI within 18 months | Financial impact analysis |

Stakeholder Access | User Adoption Rate | System implementation | Active usage of 90% among authorized users | User activity analytics |

Stakeholder Access | Training Completion | Onboarding new users | 100% completion within 30 days | Tracked via the learning management system |

Routine Review and Action Plan

Monthly Reviews: Regularly monitor these metrics each month. Address any declines immediately, and document areas of improvement for future reference.

Quarterly Analysis: Dive deeper into cost efficiency and ROI metrics every quarter. Look for patterns and adjust processes to enhance outcomes.

Annual Evaluation: At the end of each year, use the checklist as a guide for budget planning, setting performance targets, and scheduling system upgrades.

Assigning Responsibilities

For the best results, assign specific metric categories to the teams most suited to handle them. For instance:

Quality teams: Focus on data accuracy metrics like Lot ID Accuracy and Completeness.

IT departments: Oversee system performance metrics such as Query Response Time and Data Retrieval Success Rate.

Finance teams: Track cost-related metrics, including System Cost Per Unit and ROI Measurement.

This collaborative approach ensures that all aspects of the traceability process are covered effectively, leveraging the expertise of each team to maintain a robust and transparent system.

Conclusion: Using Traceability to Create Value

Strong traceability metrics turn complex and opaque value chains into systems that are clear, accountable, and trustworthy. This transparency not only strengthens stakeholder confidence but also provides a competitive edge in the marketplace.

It’s important to understand the distinction between transparency and traceability. While transparency identifies where suppliers are located, traceability goes a step further by mapping out the processes and timelines of product movements. This deeper insight is what drives meaningful improvements across the value chain.

By embedding traceability into the company’s culture, teams across departments - whether in quality control, IT, or finance - can contribute to ongoing enhancements. Regular reviews and strategic evaluations ensure that traceability efforts remain aligned with shifting market demands and stakeholder expectations.

Beyond meeting compliance requirements, traceability metrics offer an opportunity to generate lasting value throughout your operations. They act as a strategic tool, reinforcing the principles of accountability and efficiency across your value chain. For those looking to integrate traceability with broader goals, such as environmental and social impact, Council Fire provides tailored guidance to align transparency efforts with these objectives, helping organizations achieve sustainable success in managing their value chains.

FAQs

How do blockchain and IoT technologies improve traceability and transparency in supply chains?

Blockchain technology enhances traceability by establishing secure, tamper-proof records accessible to all supply chain participants in real time. This not only ensures the integrity of data but also fosters trust and provides a detailed, transparent record of a product's entire journey.

IoT devices play a vital role by continuously gathering precise data on factors like temperature, location, and movement. When integrated with blockchain, these tools create a highly transparent and dependable system. This combination minimizes fraud, boosts operational efficiency, and reinforces accountability throughout the supply chain.

What are the main challenges in creating a unified traceability system for diverse supply chain stakeholders?

Implementing a unified traceability system across a supply chain with multiple stakeholders comes with its fair share of challenges. One of the primary concerns is ensuring data accuracy and consistency. When information from various sources is incomplete or inconsistent, it can disrupt the entire traceability process, making it difficult to maintain reliable records.

Another significant obstacle is technology compatibility. Different stakeholders often rely on varying systems or outdated tools, which can create integration issues and hinder seamless communication across the supply chain.

Resistance to change is also a frequent issue. Many stakeholders may be hesitant to adopt new technologies or processes, particularly if the advantages aren’t immediately apparent. This stakeholder resistance can slow down progress and create friction within the system.

The complexity of global supply chains further complicates matters. Navigating diverse regulations, standards, and practices across regions requires a high level of coordination and adaptability. To overcome these challenges, it’s essential to foster collaboration, maintain open lines of communication, and ensure all parties are aligned with shared objectives.

How do traceability metrics help ensure compliance and maintain quality in highly regulated industries like food and pharmaceuticals?

Traceability metrics are indispensable for industries like food and pharmaceuticals, where strict regulations demand rigorous oversight. These metrics enable organizations to track and document every step of their processes, ensuring products consistently meet regulatory standards and are well-prepared for audits.

By swiftly pinpointing areas of non-compliance, traceability metrics help mitigate risks such as product recalls or legal consequences. Additionally, they encourage accountability, transparency, and ongoing improvement, all of which are crucial for fostering trust and upholding high-quality standards in these tightly regulated sectors.

Related Blog Posts

Latest Articles

©2025

FAQ

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Sep 23, 2025

Traceability Metrics Checklist for Value Chains

Sustainability Strategy

In This Article

Explore essential traceability metrics like Lot IDs and CTEs to enhance supply chain transparency, compliance, and quality management.

Traceability Metrics Checklist for Value Chains

Traceability metrics ensure products are tracked throughout the supply chain, helping businesses meet regulations, address quality concerns, and build trust. This guide explains four key metrics - Lot IDs, Critical Tracking Events (CTEs), Key Data Elements (KDEs), and Data Sharing Standards - and provides a checklist for implementing traceability systems effectively. By integrating technologies like blockchain and IoT, and fostering collaboration among supply chain partners, organizations can improve data accuracy, respond to issues faster, and enhance supply chain transparency.

Key points:

Lot IDs: Unique codes for product batches, ensuring traceability across the chain.

CTEs: Key moments in the product journey, such as production and shipping, recorded for accountability.

KDEs: Essential data like timestamps, quality tests, and environmental conditions.

Data Sharing Standards: Uniform formats (e.g., EDI, EPCIS) for seamless communication.

A successful traceability system requires mapping product flows, aligning stakeholders, and ensuring system interoperability. Regular performance reviews focus on data accuracy, accessibility, cost efficiency, and system reliability. Use this checklist to build a transparent and reliable supply chain.

A Guide to Traceability: A Practical Approach to Advance Sustainability in Global Supply Chains

Key Traceability Metrics for Value Chains

Traceability hinges on four essential metrics that enable tracking products from their origin to the consumer. Below, we break down each metric and explain how they fit into a robust traceability system.

Lot Identification Codes (Lot IDs)

Lot IDs act as unique markers for batches, shipments, or production runs within your value chain. These identifiers encapsulate critical details like origin, production date, and handling information.

A well-structured Lot ID typically includes components such as date codes, facility identifiers, and sequential batch numbers. For instance, a code like "ABC-240915-001" might signify products from facility ABC, created on September 15, 2024, as part of the first batch that day.

Standardization is key for Lot IDs to work effectively. When suppliers, manufacturers, distributors, and retailers adopt compatible systems, products can be traced seamlessly across the entire chain. This alignment is crucial for ensuring traceability, especially during recalls or quality checks, as it eliminates gaps in information.

Critical Tracking Events (CTEs)

CTEs pinpoint the key moments when products are transferred, altered, or relocated within the value chain. These events serve as checkpoints, documenting what happened to a product and when. Key CTEs include receiving raw materials, starting production, completing manufacturing, shipping finished goods, and transferring custody between partners.

Transformation events deserve special focus. These are the points where raw materials turn into finished goods or where products are modified, combined, or separated. At these stages, new Lot IDs may be generated while maintaining links to the original materials, creating a detailed product genealogy.

To reduce errors, record CTEs in real time using automated tools like barcode scanners, RFID systems, or IoT-enabled sensors.

Key Data Elements (KDEs)

KDEs capture essential information such as product descriptions, quantities, timestamps, locations, temperature logs, and quality test results. These data points form the backbone of a traceability system.

Environmental conditions are especially critical in industries like food and pharmaceuticals. Monitoring factors like temperature, humidity, and storage conditions ensures product quality and compliance with regulatory standards. For instance, cold chain products - like vaccines or fresh produce - require continuous tracking of temperature to maintain safety and effectiveness.

Quality testing results also play a vital role. Data from inspections, lab tests, and certifications provide evidence of product safety and compliance. These records are indispensable during audits or quality investigations.

Data Sharing Standards

Uniform standards, such as EDI for business transactions and EPCIS for event data, are essential for seamless data exchange across the supply chain.

EDI (Electronic Data Interchange) ensures that business documents like purchase orders, shipping notices, and invoices are formatted consistently. This standardization enables automated processing, reducing manual errors and speeding up communication between partners.

EPCIS (Electronic Product Code Information Services) offers a framework for sharing supply chain event data in a standardized format. It allows companies to communicate details about what happened to products, when and where events took place, and the reasons behind specific actions. By creating a universal "language", EPCIS facilitates visibility across industries and platforms.

These metrics form the foundation of a cohesive traceability system. Mastering them is essential for building and evaluating an effective approach to product tracking, which will be explored further in the next section.

How to Build a Traceability System

Creating a reliable traceability system demands a structured approach that tackles both technical hurdles and organizational complexities. This involves three key components working together to establish a seamless tracking framework across your entire value chain.

Process Flow Mapping

Begin by visually mapping how products move through your value chain. This step involves charting every stage, from sourcing raw materials to delivering the final product. The map should highlight where products are received, processed, stored, and shipped, pinpointing the exact points where traceability data needs to be captured.

Focus on transformation points - where products are altered or combined with other materials. These are critical spots requiring new Lot IDs while maintaining links to the original source materials. This step lays the groundwork for engaging stakeholders and integrating the necessary technology to achieve end-to-end traceability.

Map both product and data flows simultaneously. This dual perspective helps identify potential gaps where information could be lost or where manual processes might introduce errors. Pay particular attention to handoff points between organizations, as these transitions often pose the highest risk for data inconsistencies.

For temperature-sensitive items, such as cold chain products, additional mapping is essential. Continuous monitoring is crucial at key points like loading docks, transportation vehicles, and storage facilities where temperature fluctuations are most likely to occur.

Stakeholder Collaboration

Once the process flow is mapped, it's essential to align all stakeholders to ensure consistent data collection and sharing. Involve every participant in the value chain - suppliers, manufacturers, distributors, retailers, and logistics providers - from the very beginning. Their active participation is vital for the system's success.

Set clear data-sharing agreements that outline what information needs to be collected, its format, and when it should be transmitted. These agreements should also address how to handle data corrections, updates, and system downtimes or failures.

Recognize that technological capabilities will vary across your network. Larger manufacturers may use advanced ERP systems and automated tools, while smaller suppliers might rely on manual methods or basic software. Your traceability system must accommodate this diversity while ensuring the integrity and consistency of the data.

Training and ongoing support are crucial. Stakeholders need to understand not only how to use the system but also why traceability is important for the entire value chain. Regular workshops and continuous technical assistance can help maintain data quality and encourage widespread adoption.

Organizations such as Council Fire often highlight that collaboration in traceability systems can deliver benefits beyond compliance. When thoughtfully implemented, these systems can enhance transparency, strengthen relationships, and support broader social and environmental goals throughout the supply chain.

Technical and System Interoperability

Building on stakeholder collaboration, the next step is to integrate your traceability system with existing tools to ensure a smooth flow of data. Focus on integrating with current software systems like ERP platforms, warehouse management tools, and quality control systems that already house valuable traceability data. Instead of replacing these systems, establish connections that enable automatic data sharing.

Leverage API-based integrations to link systems. This reduces the need for manual data entry and ensures that traceability information remains accurate and up-to-date.

Cloud-based solutions often offer better compatibility than on-premise systems, especially when working with multiple stakeholders using varied software platforms. Cloud systems can more easily support data-sharing standards like EDI and EPCIS while scaling to handle fluctuating data volumes.

Incorporate mobile-friendly tools and strong error-checking mechanisms to capture and validate critical data. Early error detection prevents inaccuracies from spreading through the value chain.

Finally, plan for system redundancy and backup procedures to keep traceability data accessible during technical disruptions. This is especially critical in regulated industries where access to traceability records is mandatory for audits or recall scenarios requiring immediate retrieval of historical data. These measures ensure the system remains reliable and robust under all conditions.

How to Measure Traceability Performance

Once your traceability system is up and running, the next step is to evaluate how well it performs. This process ensures that the system not only functions as intended but also delivers reliable, actionable information for stakeholders. Effective measurement goes beyond simply confirming the presence of data - it focuses on whether the system provides accurate, accessible insights that enable better decision-making.

Accuracy and Completeness of Data

To ensure data accuracy, it’s critical to consistently capture Lot IDs and document each Critical Tracking Event (CTE) with precise details, such as timestamps, locations, and the responsible parties. Missing or incomplete CTE data can cause delays in corrective actions, potentially leading to larger issues.

Key Data Elements (KDEs), like temperature and quality metrics, should follow standardized units and formats to avoid confusion. For example, if suppliers report temperatures in varying units, establish a common standard (e.g., °F) or clearly indicate the unit being used. Regular validation checks should be implemented to catch errors early, preventing them from spreading through the system.

Transparency and Accessibility

A well-functioning traceability system ensures fast, secure, and comprehensive access to data. According to research from MIT Sloan School of Management, consumers are willing to pay 2% to 10% more for products with greater supply chain transparency [1]. To measure this aspect, assess response times for traceability queries across different user groups. For instance, internal quality teams might need immediate access, while external auditors may require detailed reports within specific timeframes.

Tailor data formats to meet the unique needs of various stakeholders. Retailers may only need basic origin information for consumer labels, whereas regulatory agencies might require detailed processing records. Sharing information in a secure and accessible way builds trust across the supply chain.

It’s also important to track how often stakeholders use the system. Monitoring adoption rates can highlight usability issues or indicate where additional training is needed. Once data accuracy and accessibility are ensured, focus shifts to evaluating the system’s cost and efficiency.

Cost and Efficiency

Assessing cost-effectiveness involves tracking the total system costs per unit and comparing them with the benefits, such as reduced recall expenses and quicker issue resolution.

Time efficiency is another key metric. Monitor how long it takes to handle traceability-related tasks, like responding to customer inquiries about product origins, generating regulatory reports, or conducting internal quality investigations. A well-designed system should simplify these processes without sacrificing accuracy.

Pay special attention to the financial impact on smaller suppliers within your value chain. These suppliers may face challenges due to limited technical resources, which can hinder their ability to comply with traceability requirements. Identifying and addressing these barriers - whether through technical support or simplified processes - can improve system performance.

Lastly, track the return on investment by documenting measurable benefits. This could include reduced recall costs, faster problem resolution, improved customer satisfaction, or a stronger brand reputation. Highlight specific cases where traceability data helped resolve issues quickly to justify continued investment. Additionally, monitor system performance during peak periods to identify and address capacity constraints before they affect data quality or accessibility.

Traceability Metrics Checklist Table

This checklist serves as a practical tool for assessing traceability performance and identifying areas for improvement. By turning theoretical concepts into measurable actions, it ensures a more transparent and efficient value chain.

Metric Category | Specific Metric | Application Stage | Performance Criteria | Evaluation Method |

|---|---|---|---|---|

Data Identification | Lot ID Accuracy | Product creation, processing, distribution | 99.5% accuracy rate with zero duplicate IDs | Monthly audit of ID generation systems |

Data Identification | Lot ID Completeness | All value chain stages | 100% of products have assigned IDs | Weekly sampling checks across production lines |

Critical Tracking Events | CTE Documentation | Manufacturing, packaging, shipping | All events recorded within 2 hours of occurrence | Real-time monitoring dashboards |

Critical Tracking Events | Timestamp Precision | All operational stages | Accurate to within 5 minutes of actual event | Cross-reference with production logs |

Key Data Elements | Temperature Recording | Cold chain segments | Continuous monitoring with ±1°F accuracy | Automated sensor checks |

Key Data Elements | Quality Metrics | Inspection points, final packaging | 100% compliance with predefined standards | Statistical process control charts |

Data Sharing | Information Exchange Speed | Inter-company communications | Response time under 4 business hours | Response time tracking system |

Data Sharing | Format Standardization | All external communications | 100% compliance with agreed data formats | Automated format validation checks |

System Performance | Query Response Time | Daily operations | Average response under 30 seconds | System performance monitoring |

System Performance | Data Retrieval Success Rate | Traceability investigations | 99.8% successful data retrieval | Monthly system reliability reports |

Cost Efficiency | System Cost Per Unit | Ongoing operations | Decreasing trend year-over-year | Quarterly cost analysis |

Cost Efficiency | ROI Measurement | Annual assessment | Positive ROI within 18 months | Financial impact analysis |

Stakeholder Access | User Adoption Rate | System implementation | Active usage of 90% among authorized users | User activity analytics |

Stakeholder Access | Training Completion | Onboarding new users | 100% completion within 30 days | Tracked via the learning management system |

Routine Review and Action Plan

Monthly Reviews: Regularly monitor these metrics each month. Address any declines immediately, and document areas of improvement for future reference.

Quarterly Analysis: Dive deeper into cost efficiency and ROI metrics every quarter. Look for patterns and adjust processes to enhance outcomes.

Annual Evaluation: At the end of each year, use the checklist as a guide for budget planning, setting performance targets, and scheduling system upgrades.

Assigning Responsibilities

For the best results, assign specific metric categories to the teams most suited to handle them. For instance:

Quality teams: Focus on data accuracy metrics like Lot ID Accuracy and Completeness.

IT departments: Oversee system performance metrics such as Query Response Time and Data Retrieval Success Rate.

Finance teams: Track cost-related metrics, including System Cost Per Unit and ROI Measurement.

This collaborative approach ensures that all aspects of the traceability process are covered effectively, leveraging the expertise of each team to maintain a robust and transparent system.

Conclusion: Using Traceability to Create Value

Strong traceability metrics turn complex and opaque value chains into systems that are clear, accountable, and trustworthy. This transparency not only strengthens stakeholder confidence but also provides a competitive edge in the marketplace.

It’s important to understand the distinction between transparency and traceability. While transparency identifies where suppliers are located, traceability goes a step further by mapping out the processes and timelines of product movements. This deeper insight is what drives meaningful improvements across the value chain.

By embedding traceability into the company’s culture, teams across departments - whether in quality control, IT, or finance - can contribute to ongoing enhancements. Regular reviews and strategic evaluations ensure that traceability efforts remain aligned with shifting market demands and stakeholder expectations.

Beyond meeting compliance requirements, traceability metrics offer an opportunity to generate lasting value throughout your operations. They act as a strategic tool, reinforcing the principles of accountability and efficiency across your value chain. For those looking to integrate traceability with broader goals, such as environmental and social impact, Council Fire provides tailored guidance to align transparency efforts with these objectives, helping organizations achieve sustainable success in managing their value chains.

FAQs

How do blockchain and IoT technologies improve traceability and transparency in supply chains?

Blockchain technology enhances traceability by establishing secure, tamper-proof records accessible to all supply chain participants in real time. This not only ensures the integrity of data but also fosters trust and provides a detailed, transparent record of a product's entire journey.

IoT devices play a vital role by continuously gathering precise data on factors like temperature, location, and movement. When integrated with blockchain, these tools create a highly transparent and dependable system. This combination minimizes fraud, boosts operational efficiency, and reinforces accountability throughout the supply chain.

What are the main challenges in creating a unified traceability system for diverse supply chain stakeholders?

Implementing a unified traceability system across a supply chain with multiple stakeholders comes with its fair share of challenges. One of the primary concerns is ensuring data accuracy and consistency. When information from various sources is incomplete or inconsistent, it can disrupt the entire traceability process, making it difficult to maintain reliable records.

Another significant obstacle is technology compatibility. Different stakeholders often rely on varying systems or outdated tools, which can create integration issues and hinder seamless communication across the supply chain.

Resistance to change is also a frequent issue. Many stakeholders may be hesitant to adopt new technologies or processes, particularly if the advantages aren’t immediately apparent. This stakeholder resistance can slow down progress and create friction within the system.

The complexity of global supply chains further complicates matters. Navigating diverse regulations, standards, and practices across regions requires a high level of coordination and adaptability. To overcome these challenges, it’s essential to foster collaboration, maintain open lines of communication, and ensure all parties are aligned with shared objectives.

How do traceability metrics help ensure compliance and maintain quality in highly regulated industries like food and pharmaceuticals?

Traceability metrics are indispensable for industries like food and pharmaceuticals, where strict regulations demand rigorous oversight. These metrics enable organizations to track and document every step of their processes, ensuring products consistently meet regulatory standards and are well-prepared for audits.

By swiftly pinpointing areas of non-compliance, traceability metrics help mitigate risks such as product recalls or legal consequences. Additionally, they encourage accountability, transparency, and ongoing improvement, all of which are crucial for fostering trust and upholding high-quality standards in these tightly regulated sectors.

Related Blog Posts

FAQ

01

What does it really mean to “redefine profit”?

02

What makes Council Fire different?

03

Who does Council Fire you work with?

04

What does working with Council Fire actually look like?

05

How does Council Fire help organizations turn big goals into action?

06

How does Council Fire define and measure success?

Sep 23, 2025

Traceability Metrics Checklist for Value Chains

Sustainability Strategy

In This Article

Explore essential traceability metrics like Lot IDs and CTEs to enhance supply chain transparency, compliance, and quality management.

Traceability Metrics Checklist for Value Chains

Traceability metrics ensure products are tracked throughout the supply chain, helping businesses meet regulations, address quality concerns, and build trust. This guide explains four key metrics - Lot IDs, Critical Tracking Events (CTEs), Key Data Elements (KDEs), and Data Sharing Standards - and provides a checklist for implementing traceability systems effectively. By integrating technologies like blockchain and IoT, and fostering collaboration among supply chain partners, organizations can improve data accuracy, respond to issues faster, and enhance supply chain transparency.

Key points:

Lot IDs: Unique codes for product batches, ensuring traceability across the chain.

CTEs: Key moments in the product journey, such as production and shipping, recorded for accountability.

KDEs: Essential data like timestamps, quality tests, and environmental conditions.

Data Sharing Standards: Uniform formats (e.g., EDI, EPCIS) for seamless communication.

A successful traceability system requires mapping product flows, aligning stakeholders, and ensuring system interoperability. Regular performance reviews focus on data accuracy, accessibility, cost efficiency, and system reliability. Use this checklist to build a transparent and reliable supply chain.

A Guide to Traceability: A Practical Approach to Advance Sustainability in Global Supply Chains

Key Traceability Metrics for Value Chains

Traceability hinges on four essential metrics that enable tracking products from their origin to the consumer. Below, we break down each metric and explain how they fit into a robust traceability system.

Lot Identification Codes (Lot IDs)

Lot IDs act as unique markers for batches, shipments, or production runs within your value chain. These identifiers encapsulate critical details like origin, production date, and handling information.

A well-structured Lot ID typically includes components such as date codes, facility identifiers, and sequential batch numbers. For instance, a code like "ABC-240915-001" might signify products from facility ABC, created on September 15, 2024, as part of the first batch that day.

Standardization is key for Lot IDs to work effectively. When suppliers, manufacturers, distributors, and retailers adopt compatible systems, products can be traced seamlessly across the entire chain. This alignment is crucial for ensuring traceability, especially during recalls or quality checks, as it eliminates gaps in information.

Critical Tracking Events (CTEs)

CTEs pinpoint the key moments when products are transferred, altered, or relocated within the value chain. These events serve as checkpoints, documenting what happened to a product and when. Key CTEs include receiving raw materials, starting production, completing manufacturing, shipping finished goods, and transferring custody between partners.

Transformation events deserve special focus. These are the points where raw materials turn into finished goods or where products are modified, combined, or separated. At these stages, new Lot IDs may be generated while maintaining links to the original materials, creating a detailed product genealogy.

To reduce errors, record CTEs in real time using automated tools like barcode scanners, RFID systems, or IoT-enabled sensors.

Key Data Elements (KDEs)

KDEs capture essential information such as product descriptions, quantities, timestamps, locations, temperature logs, and quality test results. These data points form the backbone of a traceability system.

Environmental conditions are especially critical in industries like food and pharmaceuticals. Monitoring factors like temperature, humidity, and storage conditions ensures product quality and compliance with regulatory standards. For instance, cold chain products - like vaccines or fresh produce - require continuous tracking of temperature to maintain safety and effectiveness.

Quality testing results also play a vital role. Data from inspections, lab tests, and certifications provide evidence of product safety and compliance. These records are indispensable during audits or quality investigations.

Data Sharing Standards

Uniform standards, such as EDI for business transactions and EPCIS for event data, are essential for seamless data exchange across the supply chain.

EDI (Electronic Data Interchange) ensures that business documents like purchase orders, shipping notices, and invoices are formatted consistently. This standardization enables automated processing, reducing manual errors and speeding up communication between partners.

EPCIS (Electronic Product Code Information Services) offers a framework for sharing supply chain event data in a standardized format. It allows companies to communicate details about what happened to products, when and where events took place, and the reasons behind specific actions. By creating a universal "language", EPCIS facilitates visibility across industries and platforms.

These metrics form the foundation of a cohesive traceability system. Mastering them is essential for building and evaluating an effective approach to product tracking, which will be explored further in the next section.

How to Build a Traceability System

Creating a reliable traceability system demands a structured approach that tackles both technical hurdles and organizational complexities. This involves three key components working together to establish a seamless tracking framework across your entire value chain.

Process Flow Mapping

Begin by visually mapping how products move through your value chain. This step involves charting every stage, from sourcing raw materials to delivering the final product. The map should highlight where products are received, processed, stored, and shipped, pinpointing the exact points where traceability data needs to be captured.

Focus on transformation points - where products are altered or combined with other materials. These are critical spots requiring new Lot IDs while maintaining links to the original source materials. This step lays the groundwork for engaging stakeholders and integrating the necessary technology to achieve end-to-end traceability.

Map both product and data flows simultaneously. This dual perspective helps identify potential gaps where information could be lost or where manual processes might introduce errors. Pay particular attention to handoff points between organizations, as these transitions often pose the highest risk for data inconsistencies.

For temperature-sensitive items, such as cold chain products, additional mapping is essential. Continuous monitoring is crucial at key points like loading docks, transportation vehicles, and storage facilities where temperature fluctuations are most likely to occur.

Stakeholder Collaboration

Once the process flow is mapped, it's essential to align all stakeholders to ensure consistent data collection and sharing. Involve every participant in the value chain - suppliers, manufacturers, distributors, retailers, and logistics providers - from the very beginning. Their active participation is vital for the system's success.

Set clear data-sharing agreements that outline what information needs to be collected, its format, and when it should be transmitted. These agreements should also address how to handle data corrections, updates, and system downtimes or failures.

Recognize that technological capabilities will vary across your network. Larger manufacturers may use advanced ERP systems and automated tools, while smaller suppliers might rely on manual methods or basic software. Your traceability system must accommodate this diversity while ensuring the integrity and consistency of the data.

Training and ongoing support are crucial. Stakeholders need to understand not only how to use the system but also why traceability is important for the entire value chain. Regular workshops and continuous technical assistance can help maintain data quality and encourage widespread adoption.

Organizations such as Council Fire often highlight that collaboration in traceability systems can deliver benefits beyond compliance. When thoughtfully implemented, these systems can enhance transparency, strengthen relationships, and support broader social and environmental goals throughout the supply chain.

Technical and System Interoperability

Building on stakeholder collaboration, the next step is to integrate your traceability system with existing tools to ensure a smooth flow of data. Focus on integrating with current software systems like ERP platforms, warehouse management tools, and quality control systems that already house valuable traceability data. Instead of replacing these systems, establish connections that enable automatic data sharing.

Leverage API-based integrations to link systems. This reduces the need for manual data entry and ensures that traceability information remains accurate and up-to-date.

Cloud-based solutions often offer better compatibility than on-premise systems, especially when working with multiple stakeholders using varied software platforms. Cloud systems can more easily support data-sharing standards like EDI and EPCIS while scaling to handle fluctuating data volumes.

Incorporate mobile-friendly tools and strong error-checking mechanisms to capture and validate critical data. Early error detection prevents inaccuracies from spreading through the value chain.

Finally, plan for system redundancy and backup procedures to keep traceability data accessible during technical disruptions. This is especially critical in regulated industries where access to traceability records is mandatory for audits or recall scenarios requiring immediate retrieval of historical data. These measures ensure the system remains reliable and robust under all conditions.

How to Measure Traceability Performance

Once your traceability system is up and running, the next step is to evaluate how well it performs. This process ensures that the system not only functions as intended but also delivers reliable, actionable information for stakeholders. Effective measurement goes beyond simply confirming the presence of data - it focuses on whether the system provides accurate, accessible insights that enable better decision-making.

Accuracy and Completeness of Data

To ensure data accuracy, it’s critical to consistently capture Lot IDs and document each Critical Tracking Event (CTE) with precise details, such as timestamps, locations, and the responsible parties. Missing or incomplete CTE data can cause delays in corrective actions, potentially leading to larger issues.

Key Data Elements (KDEs), like temperature and quality metrics, should follow standardized units and formats to avoid confusion. For example, if suppliers report temperatures in varying units, establish a common standard (e.g., °F) or clearly indicate the unit being used. Regular validation checks should be implemented to catch errors early, preventing them from spreading through the system.

Transparency and Accessibility

A well-functioning traceability system ensures fast, secure, and comprehensive access to data. According to research from MIT Sloan School of Management, consumers are willing to pay 2% to 10% more for products with greater supply chain transparency [1]. To measure this aspect, assess response times for traceability queries across different user groups. For instance, internal quality teams might need immediate access, while external auditors may require detailed reports within specific timeframes.

Tailor data formats to meet the unique needs of various stakeholders. Retailers may only need basic origin information for consumer labels, whereas regulatory agencies might require detailed processing records. Sharing information in a secure and accessible way builds trust across the supply chain.

It’s also important to track how often stakeholders use the system. Monitoring adoption rates can highlight usability issues or indicate where additional training is needed. Once data accuracy and accessibility are ensured, focus shifts to evaluating the system’s cost and efficiency.

Cost and Efficiency

Assessing cost-effectiveness involves tracking the total system costs per unit and comparing them with the benefits, such as reduced recall expenses and quicker issue resolution.

Time efficiency is another key metric. Monitor how long it takes to handle traceability-related tasks, like responding to customer inquiries about product origins, generating regulatory reports, or conducting internal quality investigations. A well-designed system should simplify these processes without sacrificing accuracy.

Pay special attention to the financial impact on smaller suppliers within your value chain. These suppliers may face challenges due to limited technical resources, which can hinder their ability to comply with traceability requirements. Identifying and addressing these barriers - whether through technical support or simplified processes - can improve system performance.

Lastly, track the return on investment by documenting measurable benefits. This could include reduced recall costs, faster problem resolution, improved customer satisfaction, or a stronger brand reputation. Highlight specific cases where traceability data helped resolve issues quickly to justify continued investment. Additionally, monitor system performance during peak periods to identify and address capacity constraints before they affect data quality or accessibility.

Traceability Metrics Checklist Table

This checklist serves as a practical tool for assessing traceability performance and identifying areas for improvement. By turning theoretical concepts into measurable actions, it ensures a more transparent and efficient value chain.

Metric Category | Specific Metric | Application Stage | Performance Criteria | Evaluation Method |

|---|---|---|---|---|

Data Identification | Lot ID Accuracy | Product creation, processing, distribution | 99.5% accuracy rate with zero duplicate IDs | Monthly audit of ID generation systems |

Data Identification | Lot ID Completeness | All value chain stages | 100% of products have assigned IDs | Weekly sampling checks across production lines |

Critical Tracking Events | CTE Documentation | Manufacturing, packaging, shipping | All events recorded within 2 hours of occurrence | Real-time monitoring dashboards |

Critical Tracking Events | Timestamp Precision | All operational stages | Accurate to within 5 minutes of actual event | Cross-reference with production logs |

Key Data Elements | Temperature Recording | Cold chain segments | Continuous monitoring with ±1°F accuracy | Automated sensor checks |

Key Data Elements | Quality Metrics | Inspection points, final packaging | 100% compliance with predefined standards | Statistical process control charts |

Data Sharing | Information Exchange Speed | Inter-company communications | Response time under 4 business hours | Response time tracking system |

Data Sharing | Format Standardization | All external communications | 100% compliance with agreed data formats | Automated format validation checks |

System Performance | Query Response Time | Daily operations | Average response under 30 seconds | System performance monitoring |

System Performance | Data Retrieval Success Rate | Traceability investigations | 99.8% successful data retrieval | Monthly system reliability reports |

Cost Efficiency | System Cost Per Unit | Ongoing operations | Decreasing trend year-over-year | Quarterly cost analysis |

Cost Efficiency | ROI Measurement | Annual assessment | Positive ROI within 18 months | Financial impact analysis |

Stakeholder Access | User Adoption Rate | System implementation | Active usage of 90% among authorized users | User activity analytics |

Stakeholder Access | Training Completion | Onboarding new users | 100% completion within 30 days | Tracked via the learning management system |

Routine Review and Action Plan

Monthly Reviews: Regularly monitor these metrics each month. Address any declines immediately, and document areas of improvement for future reference.

Quarterly Analysis: Dive deeper into cost efficiency and ROI metrics every quarter. Look for patterns and adjust processes to enhance outcomes.

Annual Evaluation: At the end of each year, use the checklist as a guide for budget planning, setting performance targets, and scheduling system upgrades.

Assigning Responsibilities

For the best results, assign specific metric categories to the teams most suited to handle them. For instance:

Quality teams: Focus on data accuracy metrics like Lot ID Accuracy and Completeness.

IT departments: Oversee system performance metrics such as Query Response Time and Data Retrieval Success Rate.

Finance teams: Track cost-related metrics, including System Cost Per Unit and ROI Measurement.

This collaborative approach ensures that all aspects of the traceability process are covered effectively, leveraging the expertise of each team to maintain a robust and transparent system.

Conclusion: Using Traceability to Create Value

Strong traceability metrics turn complex and opaque value chains into systems that are clear, accountable, and trustworthy. This transparency not only strengthens stakeholder confidence but also provides a competitive edge in the marketplace.

It’s important to understand the distinction between transparency and traceability. While transparency identifies where suppliers are located, traceability goes a step further by mapping out the processes and timelines of product movements. This deeper insight is what drives meaningful improvements across the value chain.

By embedding traceability into the company’s culture, teams across departments - whether in quality control, IT, or finance - can contribute to ongoing enhancements. Regular reviews and strategic evaluations ensure that traceability efforts remain aligned with shifting market demands and stakeholder expectations.

Beyond meeting compliance requirements, traceability metrics offer an opportunity to generate lasting value throughout your operations. They act as a strategic tool, reinforcing the principles of accountability and efficiency across your value chain. For those looking to integrate traceability with broader goals, such as environmental and social impact, Council Fire provides tailored guidance to align transparency efforts with these objectives, helping organizations achieve sustainable success in managing their value chains.

FAQs

How do blockchain and IoT technologies improve traceability and transparency in supply chains?

Blockchain technology enhances traceability by establishing secure, tamper-proof records accessible to all supply chain participants in real time. This not only ensures the integrity of data but also fosters trust and provides a detailed, transparent record of a product's entire journey.

IoT devices play a vital role by continuously gathering precise data on factors like temperature, location, and movement. When integrated with blockchain, these tools create a highly transparent and dependable system. This combination minimizes fraud, boosts operational efficiency, and reinforces accountability throughout the supply chain.

What are the main challenges in creating a unified traceability system for diverse supply chain stakeholders?

Implementing a unified traceability system across a supply chain with multiple stakeholders comes with its fair share of challenges. One of the primary concerns is ensuring data accuracy and consistency. When information from various sources is incomplete or inconsistent, it can disrupt the entire traceability process, making it difficult to maintain reliable records.

Another significant obstacle is technology compatibility. Different stakeholders often rely on varying systems or outdated tools, which can create integration issues and hinder seamless communication across the supply chain.

Resistance to change is also a frequent issue. Many stakeholders may be hesitant to adopt new technologies or processes, particularly if the advantages aren’t immediately apparent. This stakeholder resistance can slow down progress and create friction within the system.

The complexity of global supply chains further complicates matters. Navigating diverse regulations, standards, and practices across regions requires a high level of coordination and adaptability. To overcome these challenges, it’s essential to foster collaboration, maintain open lines of communication, and ensure all parties are aligned with shared objectives.

How do traceability metrics help ensure compliance and maintain quality in highly regulated industries like food and pharmaceuticals?

Traceability metrics are indispensable for industries like food and pharmaceuticals, where strict regulations demand rigorous oversight. These metrics enable organizations to track and document every step of their processes, ensuring products consistently meet regulatory standards and are well-prepared for audits.

By swiftly pinpointing areas of non-compliance, traceability metrics help mitigate risks such as product recalls or legal consequences. Additionally, they encourage accountability, transparency, and ongoing improvement, all of which are crucial for fostering trust and upholding high-quality standards in these tightly regulated sectors.

Related Blog Posts

FAQ

What does it really mean to “redefine profit”?

What makes Council Fire different?

Who does Council Fire you work with?

What does working with Council Fire actually look like?

How does Council Fire help organizations turn big goals into action?

How does Council Fire define and measure success?