Aug 21, 2025

Case Study: Energy Efficiency in Eco-Industrial Parks

Sustainability Strategy

case-study-energy-efficiency-in-eco-industrial-parks

case-study-energy-efficiency-in-eco-industrial-parks

Eco-industrial parks are reshaping how businesses operate by creating interconnected systems where resources, energy, and waste are shared. This approach reduces costs, improves energy use, and cuts environmental impact. These parks use shared renewable energy systems, advanced energy management tools, and collaborative business models to optimize operations. The result? Lower expenses for companies, cleaner air, and job opportunities for communities.

Key takeaways:

Energy Sharing: Businesses exchange resources like waste heat, steam, and electricity to reduce energy waste.

Energy Mapping: Real-time data identifies inefficiencies and matches renewable energy sources with demand.

Collaborative Management: Joint ownership of energy systems and shared infrastructure drives efficiency.

Global Examples: Kenya's geothermal park, Chicago's food hub, Finland's district heating network, and Canada’s integrated systems highlight successful models.

The U.S. can benefit by implementing policies that support these systems, tailoring solutions to local industries, and encouraging collaboration among businesses, governments, and communities. With the right approach, eco-industrial parks can reduce costs, improve resource use, and support economic growth.

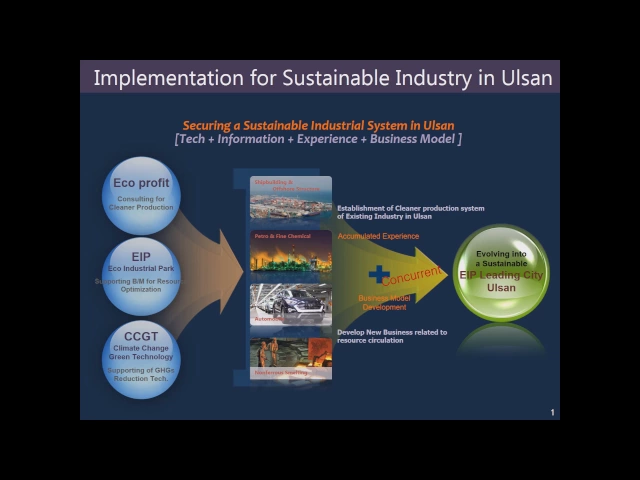

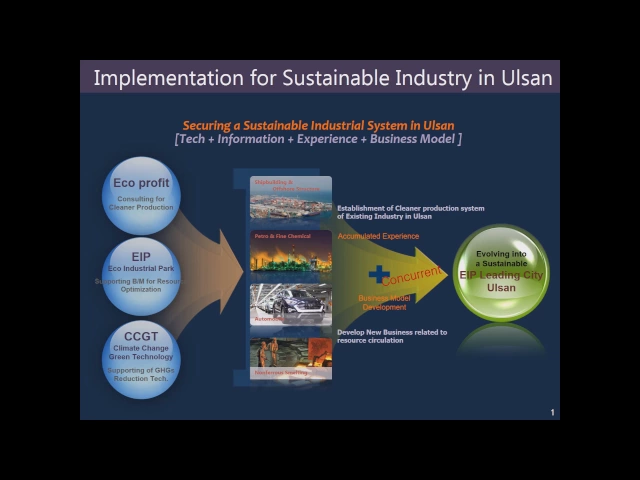

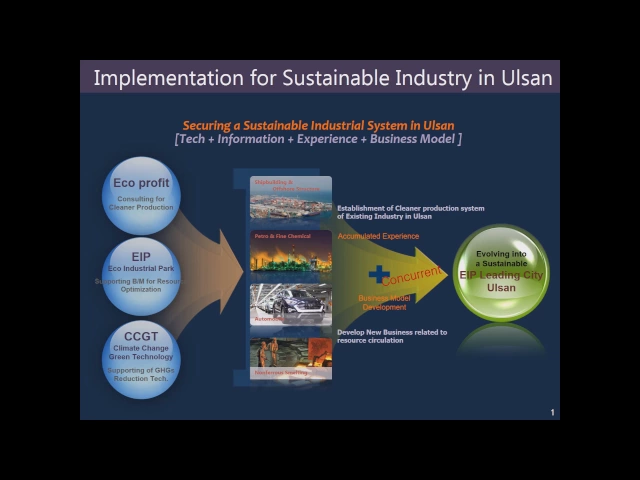

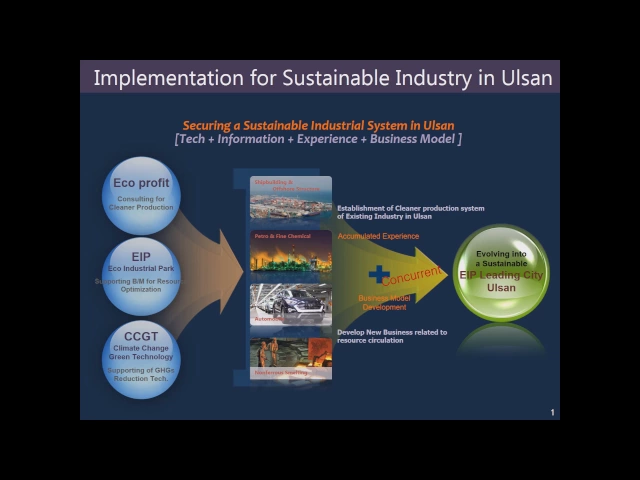

Eco Industrial Park Development - The Ulsan Experience

Design Principles for Energy-Efficient Eco-Industrial Parks

Eco-industrial parks thrive on energy-efficient designs and shared resources, creating systems that cut waste and lower costs. These parks adopt strategies that encourage collaboration among businesses, turning them into interconnected networks. By following key principles, these parks achieve significant energy savings while promoting teamwork, as seen in projects around the globe.

Industrial Symbiosis and Resource Sharing

Industrial symbiosis connects businesses so that one company’s waste, like excess steam or heat, becomes another’s resource. This setup can lead to major energy savings. For example, companies can share steam, hot water, electricity, or even waste heat generated during manufacturing.

This method works best when businesses with complementary energy needs are located close to one another. Picture a steel mill producing excess steam that powers a nearby chemical plant. Or imagine a power plant supplying electricity to several manufacturers while using organic waste as biomass fuel. These partnerships align energy needs and reduce overall costs.

Instead of individual companies investing in smaller, separate renewable energy systems, the entire park can pool resources to install larger, more efficient systems like solar panels or wind turbines. This collective effort not only lowers the cost per kilowatt-hour but also ensures more stable power generation, benefiting all participants.

By aligning energy supply with demand, businesses can maximize the efficiency of shared resources, paving the way for precise energy mapping.

Energy Mapping and Flow Analysis

To optimize energy use, understanding how it flows through an eco-industrial park is critical. Energy mapping tracks power sources, consumption patterns, and waste heat production across all participating businesses. This detailed analysis uncovers opportunities that often go unnoticed when companies operate independently.

With tools like smart meters and sensors, real-time energy flows can be monitored, and inefficiencies quickly identified. For instance, waste heat from a textile manufacturer could be used to power a neighboring food processor’s drying operations. Such insights open doors to energy-sharing opportunities that benefit multiple businesses.

Material flow tracking adds another layer of efficiency by analyzing the movement of raw materials, water, and waste products. For example, a paper mill’s wastewater could generate biogas for electricity, while wood chips from packaging operations might fuel biomass boilers.

Energy mapping also improves the integration of renewable energy systems. Instead of relying on theoretical projections, data-driven insights help determine the best locations for solar panels, wind turbines, and energy storage systems based on actual consumption patterns. This approach ensures renewable energy is used where it’s needed most.

Collaborative Management Models

Identifying energy-saving opportunities is just the beginning - effective management structures are essential to put these ideas into action. Collaborative management models bring together representatives from participating companies to oversee shared infrastructure, energy purchasing, and resource distribution. This ensures that all businesses benefit from the park’s energy initiatives.

Joint ownership of renewable energy installations, like solar farms, allows companies to share costs and reap proportional benefits. Regular coordination meetings help align operations and identify new opportunities for synergy as businesses evolve or invest in new equipment.

Internal financial tools, such as carbon pricing or energy credits, encourage energy-efficient practices. Some parks reward companies that reduce consumption or share resources, while others offer revolving loan funds to support investments in energy-efficient technologies.

Collaboration often extends beyond the park itself. Engaging with local utilities, government agencies, and community stakeholders can secure benefits like favorable electricity rates, regulatory support, and public backing for future expansions. These partnerships make it easier to achieve shared energy goals.

The following case studies demonstrate how these principles come to life, showcasing real-world examples of energy-efficient practices in action.

Case Studies of Energy Efficiency in Eco-Industrial Parks

Examples from around the world show how eco-industrial parks turn energy efficiency concepts into real, measurable results. These parks rethink traditional industrial practices by fostering collaboration, integrating renewable energy, and using strategic planning to benefit both businesses and their surrounding communities.

Here are a few standout examples of how these principles are applied in practice:

KenGen Green Energy Park (Kenya)

Kenya's KenGen Green Energy Park in Naivasha is a trailblazer in renewable energy use across Africa. This facility combines geothermal power production with sustainable industrial operations, creating a blueprint for energy-efficient growth. By utilizing hybrid renewable systems and capturing waste heat to support local agriculture, the park demonstrates how efficient energy management can drive both community growth and operational harmony.

Testa Produce Inc. (Chicago, USA)

Testa Produce Inc., based in Chicago, has overhauled its operations by embracing renewable energy and smart energy solutions. The company has installed solar panels, upgraded to energy-saving lighting systems, and implemented advanced monitoring tools to track and reduce energy use. On top of that, efficient waste processing and optimized cold storage systems have helped the company make better use of resources while improving overall performance.

Harjavalta Eco-Industrial Park (Finland)

Finland’s Harjavalta Eco-Industrial Park highlights the benefits of transitioning to sustainable energy systems. The park has adopted district heating networks, significantly cutting down its reliance on fossil fuels. By fostering collaboration among the businesses within the park, it has enabled resource sharing that boosts energy efficiency while also supporting circular economy initiatives.

Sarnia-Lambton Eco-Industrial Park (Canada)

Located in Ontario, the Sarnia-Lambton Eco-Industrial Park has become a leader in eco-friendly industrial practices. The park integrates renewable energy systems with advanced resource management, bringing together multiple companies dedicated to cutting carbon emissions and improving energy efficiency. Features like diverse renewable installations, energy storage solutions, and integrated water and waste systems form the backbone of its sustainable setup. This transformation has been backed by strong government support and close collaboration among industry players, establishing a model for future eco-industrial developments.

These examples highlight the potential of eco-industrial parks to advance energy efficiency while addressing environmental and community needs. They also provide a foundation for exploring the key factors behind their success and the challenges they face.

Success Factors and Challenges

Success Factors

Transforming traditional industrial parks into energy-efficient eco-industrial systems is no small feat. It requires a well-coordinated effort across several key areas to ensure success:

Collaboration among stakeholders: Bringing together businesses, local governments, and community members is essential. This collective effort creates a foundation for shared goals and meaningful progress.

Access to financial resources and incentives: Government subsidies, tax breaks, and long-term energy savings make the transition more financially appealing, helping to offset initial costs and encourage sustainable practices.

Symbiotic business relationships: When companies within the park share by-products, energy, and water resources, waste is reduced, and overall efficiency improves. This interconnected approach benefits everyone involved.

Advanced technologies: Investments in modern tools like renewable energy systems, cleaner production methods, and advanced monitoring technologies drive continuous improvements and adaptability.

Supportive regulations: Policies and frameworks that encourage sustainable practices are critical for long-term success.

Knowledge sharing and training: Regular education and capacity-building efforts help stakeholders understand the benefits and processes of energy-efficient practices, speeding up adoption across the board.

By focusing on these factors, the transition to eco-industrial systems becomes more achievable, and the overall impact is maximized.

Role of Expert Consulting

Expert consultants play a pivotal role in turning these success factors into actionable strategies. They simplify the complex process of creating eco-industrial parks by aligning stakeholders and streamlining collaboration.

Consultants provide in-depth technical and financial analyses, helping businesses assess energy-sharing opportunities, calculate returns on investment, and design scalable energy models. They also guide organizations through regulatory requirements, ensuring compliance and helping them tap into available incentives.

Beyond analysis, consultants focus on capacity building. Through tailored training programs, they equip leaders and energy managers with the tools and knowledge needed to implement innovative solutions. This hands-on support often determines whether a project encounters roadblocks or achieves lasting success.

Recommendations for the United States

The United States has a unique opportunity to take the lead in developing energy-efficient eco-industrial parks. By learning from successful international models, several strategies can help accelerate progress and make a meaningful difference across the country’s industrial landscape. It all starts with implementing policies that create room for region-specific, tailored solutions.

Policy and Incentive Frameworks

Building a strong policy foundation is crucial for expanding eco-industrial parks nationwide. On the federal level, offering targeted tax credits to companies participating in industrial symbiosis networks could help offset the upfront costs of infrastructure for energy-sharing systems and waste-to-energy projects. At the state level, policies like streamlined permitting can provide additional support. For example, California’s renewable energy zones have shown how pre-approved utility connections and expedited environmental reviews can lower barriers for new projects.

Performance-based incentives can also play a significant role. Multi-year programs that reward companies for meeting specific energy reduction goals encourage ongoing efficiency improvements and innovation. Additionally, partnerships with regional utilities could be a game-changer. Public utility commissions might offer discounted rates to eco-industrial parks that stabilize the grid through demand balancing and distributed energy generation. This approach transforms these parks into assets for the energy grid, rather than just energy consumers.

Customized Solutions

Once supportive policies are in place, solutions tailored to regional needs become essential. The U.S. industrial landscape is incredibly diverse, and strategies should reflect local strengths and conditions. For instance:

In manufacturing-heavy regions like the Great Lakes, thermal energy-sharing networks can allow facilities to exchange waste heat and steam, making use of existing infrastructure.

Technology hubs in states like Texas, North Carolina, and Arizona can integrate data centers with nearby manufacturing plants. Here, the waste heat from data centers could support production processes, while their consistent electricity demand helps stabilize renewable energy sources.

Agricultural areas present opportunities for bio-industrial symbiosis. Food processing plants, biofuel producers, and livestock operations could collaborate to create closed-loop systems, turning organic waste into energy feedstock.

Coastal port cities can leverage their logistics advantages to develop eco-industrial clusters, combining container terminals, freight rail, and distribution centers to optimize energy use and transportation efficiency.

Financing mechanisms should also align with local economic realities. For example, USDA rural development programs could be adapted for eco-industrial projects, or municipal bonds could fund public-private partnerships in urban areas.

Stakeholder Collaboration and Impact Analysis

Collaboration among stakeholders is at the heart of successful eco-industrial initiatives. Regional economic development organizations can bring together manufacturers, utilities, local governments, and community leaders to work toward shared economic and environmental goals.

Data-driven impact analysis is key to keeping stakeholders engaged. Conducting baseline assessments of energy flows, waste streams, and economic impacts can highlight the benefits of eco-industrial practices, such as improved environmental performance, job creation, and increased tax revenue. These assessments also help demonstrate how these initiatives contribute to community well-being.

Pilot projects can serve as a starting point, allowing companies to test energy-sharing arrangements on a smaller scale. These demonstrations provide tangible results and cost-benefit data that can encourage broader participation. By building on proven collaborative models, stakeholders can establish clear impact metrics and foster community engagement, which helps secure the social support needed for eco-industrial development.

Expert consultants, such as Council Fire, can play a vital role in coordinating these efforts. With experience in energy infrastructure and sustainable development, they can help align technical requirements with economic and environmental goals, ensuring that these parks deliver both financial and ecological benefits.

Long-term governance structures are also essential. Eco-industrial parks need ongoing coordination mechanisms that can adapt to changing business conditions, new technologies, and regulatory updates. These structures should include representatives from all key stakeholder groups and provide clear decision-making processes to maintain energy efficiency and economic impact over time.

Conclusion: Driving Change Through Energy-Efficient Eco-Industrial Parks

Real-world examples show that energy-efficient eco-industrial parks aren't just a concept - they deliver measurable results. These case studies highlight how thoughtful planning and collaboration can reshape industrial practices for the better.

To succeed, these parks rely on a few key elements: smart design that encourages industrial symbiosis, active collaboration among stakeholders, and expert guidance throughout the process. Add to that detailed energy mapping and continuous coordination, and you’ve got a strong foundation for future progress, particularly in the U.S.

Regional strategies play a huge role in making these parks effective. In the United States, adapting successful global models to fit local needs and economic conditions is critical. Learning from international successes, while tailoring them to domestic realities, ensures these parks can thrive. Expert organizations, like Council Fire, bring the know-how to align energy projects with broader economic and environmental goals. Their ability to foster collaboration and perform impact analysis helps ensure these parks deliver real benefits for businesses and communities alike.

Eco-industrial parks focused on energy efficiency bring lasting advantages: lower operating costs, better environmental outcomes, and stronger local economies. The real challenge isn’t whether these parks work - it’s how quickly industries and policymakers in the U.S. will embrace this collaborative approach to reshape the industrial landscape.

The path forward demands commitment from everyone involved. But the payoff - both financially and environmentally - makes eco-industrial parks one of the most promising ways to achieve large-scale sustainable industrial growth.

FAQs

How do eco-industrial parks help protect the environment while boosting local economies?

Eco-industrial parks (EIPs) play an important role in cutting down waste, conserving resources, and reducing pollution. These efforts result in cleaner production methods and help lower greenhouse gas emissions. By incorporating renewable energy sources and energy-efficient technologies, EIPs take sustainability efforts to the next level.

Beyond environmental benefits, EIPs contribute to local economies by generating jobs, attracting investments, and driving long-term economic growth. They create a collaborative space where businesses can share resources and cut costs, striking a balance between economic progress and environmental care.

What factors contribute to the success of eco-industrial parks in achieving energy efficiency and collaboration?

Eco-industrial parks thrive by encouraging resource-sharing partnerships among businesses. This means companies exchange energy, materials, and waste streams, reducing waste while boosting efficiency. The key to making this work lies in strong stakeholder involvement and adopting practices that save costs and use resources wisely.

Another driving force is the collaboration between government and industry, which helps set the stage for success. Performance monitoring systems and shared energy initiatives also play a vital role. Together, these efforts not only enhance energy efficiency but also build a cooperative atmosphere that benefits businesses and the local community alike.

What policies can the United States adopt to encourage energy-efficient eco-industrial parks?

The United States has the potential to lead the way in creating energy-efficient eco-industrial parks by implementing policies that promote renewable energy use and better resource management. This could involve providing incentives for adopting clean technologies, simplifying regulations to make investments easier, and encouraging industries to adopt energy-saving practices.

Laws that back market-driven incentives and encourage private sector innovation can push this effort even further. By connecting environmental objectives with economic advantages, such policies can pave the way for industrial hubs that support both businesses and local communities across the country.

Related posts

FAQ

01

What does a project look like?

02

How is the pricing structure?

03

Are all projects fixed scope?

04

What is the ROI?

05

How do we measure success?

06

What do I need to get started?

07

How easy is it to edit for beginners?

08

Do I need to know how to code?

Aug 21, 2025

Case Study: Energy Efficiency in Eco-Industrial Parks

Sustainability Strategy

case-study-energy-efficiency-in-eco-industrial-parks

case-study-energy-efficiency-in-eco-industrial-parks

Eco-industrial parks are reshaping how businesses operate by creating interconnected systems where resources, energy, and waste are shared. This approach reduces costs, improves energy use, and cuts environmental impact. These parks use shared renewable energy systems, advanced energy management tools, and collaborative business models to optimize operations. The result? Lower expenses for companies, cleaner air, and job opportunities for communities.

Key takeaways:

Energy Sharing: Businesses exchange resources like waste heat, steam, and electricity to reduce energy waste.

Energy Mapping: Real-time data identifies inefficiencies and matches renewable energy sources with demand.

Collaborative Management: Joint ownership of energy systems and shared infrastructure drives efficiency.

Global Examples: Kenya's geothermal park, Chicago's food hub, Finland's district heating network, and Canada’s integrated systems highlight successful models.

The U.S. can benefit by implementing policies that support these systems, tailoring solutions to local industries, and encouraging collaboration among businesses, governments, and communities. With the right approach, eco-industrial parks can reduce costs, improve resource use, and support economic growth.

Eco Industrial Park Development - The Ulsan Experience

Design Principles for Energy-Efficient Eco-Industrial Parks

Eco-industrial parks thrive on energy-efficient designs and shared resources, creating systems that cut waste and lower costs. These parks adopt strategies that encourage collaboration among businesses, turning them into interconnected networks. By following key principles, these parks achieve significant energy savings while promoting teamwork, as seen in projects around the globe.

Industrial Symbiosis and Resource Sharing

Industrial symbiosis connects businesses so that one company’s waste, like excess steam or heat, becomes another’s resource. This setup can lead to major energy savings. For example, companies can share steam, hot water, electricity, or even waste heat generated during manufacturing.

This method works best when businesses with complementary energy needs are located close to one another. Picture a steel mill producing excess steam that powers a nearby chemical plant. Or imagine a power plant supplying electricity to several manufacturers while using organic waste as biomass fuel. These partnerships align energy needs and reduce overall costs.

Instead of individual companies investing in smaller, separate renewable energy systems, the entire park can pool resources to install larger, more efficient systems like solar panels or wind turbines. This collective effort not only lowers the cost per kilowatt-hour but also ensures more stable power generation, benefiting all participants.

By aligning energy supply with demand, businesses can maximize the efficiency of shared resources, paving the way for precise energy mapping.

Energy Mapping and Flow Analysis

To optimize energy use, understanding how it flows through an eco-industrial park is critical. Energy mapping tracks power sources, consumption patterns, and waste heat production across all participating businesses. This detailed analysis uncovers opportunities that often go unnoticed when companies operate independently.

With tools like smart meters and sensors, real-time energy flows can be monitored, and inefficiencies quickly identified. For instance, waste heat from a textile manufacturer could be used to power a neighboring food processor’s drying operations. Such insights open doors to energy-sharing opportunities that benefit multiple businesses.

Material flow tracking adds another layer of efficiency by analyzing the movement of raw materials, water, and waste products. For example, a paper mill’s wastewater could generate biogas for electricity, while wood chips from packaging operations might fuel biomass boilers.

Energy mapping also improves the integration of renewable energy systems. Instead of relying on theoretical projections, data-driven insights help determine the best locations for solar panels, wind turbines, and energy storage systems based on actual consumption patterns. This approach ensures renewable energy is used where it’s needed most.

Collaborative Management Models

Identifying energy-saving opportunities is just the beginning - effective management structures are essential to put these ideas into action. Collaborative management models bring together representatives from participating companies to oversee shared infrastructure, energy purchasing, and resource distribution. This ensures that all businesses benefit from the park’s energy initiatives.

Joint ownership of renewable energy installations, like solar farms, allows companies to share costs and reap proportional benefits. Regular coordination meetings help align operations and identify new opportunities for synergy as businesses evolve or invest in new equipment.

Internal financial tools, such as carbon pricing or energy credits, encourage energy-efficient practices. Some parks reward companies that reduce consumption or share resources, while others offer revolving loan funds to support investments in energy-efficient technologies.

Collaboration often extends beyond the park itself. Engaging with local utilities, government agencies, and community stakeholders can secure benefits like favorable electricity rates, regulatory support, and public backing for future expansions. These partnerships make it easier to achieve shared energy goals.

The following case studies demonstrate how these principles come to life, showcasing real-world examples of energy-efficient practices in action.

Case Studies of Energy Efficiency in Eco-Industrial Parks

Examples from around the world show how eco-industrial parks turn energy efficiency concepts into real, measurable results. These parks rethink traditional industrial practices by fostering collaboration, integrating renewable energy, and using strategic planning to benefit both businesses and their surrounding communities.

Here are a few standout examples of how these principles are applied in practice:

KenGen Green Energy Park (Kenya)

Kenya's KenGen Green Energy Park in Naivasha is a trailblazer in renewable energy use across Africa. This facility combines geothermal power production with sustainable industrial operations, creating a blueprint for energy-efficient growth. By utilizing hybrid renewable systems and capturing waste heat to support local agriculture, the park demonstrates how efficient energy management can drive both community growth and operational harmony.

Testa Produce Inc. (Chicago, USA)

Testa Produce Inc., based in Chicago, has overhauled its operations by embracing renewable energy and smart energy solutions. The company has installed solar panels, upgraded to energy-saving lighting systems, and implemented advanced monitoring tools to track and reduce energy use. On top of that, efficient waste processing and optimized cold storage systems have helped the company make better use of resources while improving overall performance.

Harjavalta Eco-Industrial Park (Finland)

Finland’s Harjavalta Eco-Industrial Park highlights the benefits of transitioning to sustainable energy systems. The park has adopted district heating networks, significantly cutting down its reliance on fossil fuels. By fostering collaboration among the businesses within the park, it has enabled resource sharing that boosts energy efficiency while also supporting circular economy initiatives.

Sarnia-Lambton Eco-Industrial Park (Canada)

Located in Ontario, the Sarnia-Lambton Eco-Industrial Park has become a leader in eco-friendly industrial practices. The park integrates renewable energy systems with advanced resource management, bringing together multiple companies dedicated to cutting carbon emissions and improving energy efficiency. Features like diverse renewable installations, energy storage solutions, and integrated water and waste systems form the backbone of its sustainable setup. This transformation has been backed by strong government support and close collaboration among industry players, establishing a model for future eco-industrial developments.

These examples highlight the potential of eco-industrial parks to advance energy efficiency while addressing environmental and community needs. They also provide a foundation for exploring the key factors behind their success and the challenges they face.

Success Factors and Challenges

Success Factors

Transforming traditional industrial parks into energy-efficient eco-industrial systems is no small feat. It requires a well-coordinated effort across several key areas to ensure success:

Collaboration among stakeholders: Bringing together businesses, local governments, and community members is essential. This collective effort creates a foundation for shared goals and meaningful progress.

Access to financial resources and incentives: Government subsidies, tax breaks, and long-term energy savings make the transition more financially appealing, helping to offset initial costs and encourage sustainable practices.

Symbiotic business relationships: When companies within the park share by-products, energy, and water resources, waste is reduced, and overall efficiency improves. This interconnected approach benefits everyone involved.

Advanced technologies: Investments in modern tools like renewable energy systems, cleaner production methods, and advanced monitoring technologies drive continuous improvements and adaptability.

Supportive regulations: Policies and frameworks that encourage sustainable practices are critical for long-term success.

Knowledge sharing and training: Regular education and capacity-building efforts help stakeholders understand the benefits and processes of energy-efficient practices, speeding up adoption across the board.

By focusing on these factors, the transition to eco-industrial systems becomes more achievable, and the overall impact is maximized.

Role of Expert Consulting

Expert consultants play a pivotal role in turning these success factors into actionable strategies. They simplify the complex process of creating eco-industrial parks by aligning stakeholders and streamlining collaboration.

Consultants provide in-depth technical and financial analyses, helping businesses assess energy-sharing opportunities, calculate returns on investment, and design scalable energy models. They also guide organizations through regulatory requirements, ensuring compliance and helping them tap into available incentives.

Beyond analysis, consultants focus on capacity building. Through tailored training programs, they equip leaders and energy managers with the tools and knowledge needed to implement innovative solutions. This hands-on support often determines whether a project encounters roadblocks or achieves lasting success.

Recommendations for the United States

The United States has a unique opportunity to take the lead in developing energy-efficient eco-industrial parks. By learning from successful international models, several strategies can help accelerate progress and make a meaningful difference across the country’s industrial landscape. It all starts with implementing policies that create room for region-specific, tailored solutions.

Policy and Incentive Frameworks

Building a strong policy foundation is crucial for expanding eco-industrial parks nationwide. On the federal level, offering targeted tax credits to companies participating in industrial symbiosis networks could help offset the upfront costs of infrastructure for energy-sharing systems and waste-to-energy projects. At the state level, policies like streamlined permitting can provide additional support. For example, California’s renewable energy zones have shown how pre-approved utility connections and expedited environmental reviews can lower barriers for new projects.

Performance-based incentives can also play a significant role. Multi-year programs that reward companies for meeting specific energy reduction goals encourage ongoing efficiency improvements and innovation. Additionally, partnerships with regional utilities could be a game-changer. Public utility commissions might offer discounted rates to eco-industrial parks that stabilize the grid through demand balancing and distributed energy generation. This approach transforms these parks into assets for the energy grid, rather than just energy consumers.

Customized Solutions

Once supportive policies are in place, solutions tailored to regional needs become essential. The U.S. industrial landscape is incredibly diverse, and strategies should reflect local strengths and conditions. For instance:

In manufacturing-heavy regions like the Great Lakes, thermal energy-sharing networks can allow facilities to exchange waste heat and steam, making use of existing infrastructure.

Technology hubs in states like Texas, North Carolina, and Arizona can integrate data centers with nearby manufacturing plants. Here, the waste heat from data centers could support production processes, while their consistent electricity demand helps stabilize renewable energy sources.

Agricultural areas present opportunities for bio-industrial symbiosis. Food processing plants, biofuel producers, and livestock operations could collaborate to create closed-loop systems, turning organic waste into energy feedstock.

Coastal port cities can leverage their logistics advantages to develop eco-industrial clusters, combining container terminals, freight rail, and distribution centers to optimize energy use and transportation efficiency.

Financing mechanisms should also align with local economic realities. For example, USDA rural development programs could be adapted for eco-industrial projects, or municipal bonds could fund public-private partnerships in urban areas.

Stakeholder Collaboration and Impact Analysis

Collaboration among stakeholders is at the heart of successful eco-industrial initiatives. Regional economic development organizations can bring together manufacturers, utilities, local governments, and community leaders to work toward shared economic and environmental goals.

Data-driven impact analysis is key to keeping stakeholders engaged. Conducting baseline assessments of energy flows, waste streams, and economic impacts can highlight the benefits of eco-industrial practices, such as improved environmental performance, job creation, and increased tax revenue. These assessments also help demonstrate how these initiatives contribute to community well-being.

Pilot projects can serve as a starting point, allowing companies to test energy-sharing arrangements on a smaller scale. These demonstrations provide tangible results and cost-benefit data that can encourage broader participation. By building on proven collaborative models, stakeholders can establish clear impact metrics and foster community engagement, which helps secure the social support needed for eco-industrial development.

Expert consultants, such as Council Fire, can play a vital role in coordinating these efforts. With experience in energy infrastructure and sustainable development, they can help align technical requirements with economic and environmental goals, ensuring that these parks deliver both financial and ecological benefits.

Long-term governance structures are also essential. Eco-industrial parks need ongoing coordination mechanisms that can adapt to changing business conditions, new technologies, and regulatory updates. These structures should include representatives from all key stakeholder groups and provide clear decision-making processes to maintain energy efficiency and economic impact over time.

Conclusion: Driving Change Through Energy-Efficient Eco-Industrial Parks

Real-world examples show that energy-efficient eco-industrial parks aren't just a concept - they deliver measurable results. These case studies highlight how thoughtful planning and collaboration can reshape industrial practices for the better.

To succeed, these parks rely on a few key elements: smart design that encourages industrial symbiosis, active collaboration among stakeholders, and expert guidance throughout the process. Add to that detailed energy mapping and continuous coordination, and you’ve got a strong foundation for future progress, particularly in the U.S.

Regional strategies play a huge role in making these parks effective. In the United States, adapting successful global models to fit local needs and economic conditions is critical. Learning from international successes, while tailoring them to domestic realities, ensures these parks can thrive. Expert organizations, like Council Fire, bring the know-how to align energy projects with broader economic and environmental goals. Their ability to foster collaboration and perform impact analysis helps ensure these parks deliver real benefits for businesses and communities alike.

Eco-industrial parks focused on energy efficiency bring lasting advantages: lower operating costs, better environmental outcomes, and stronger local economies. The real challenge isn’t whether these parks work - it’s how quickly industries and policymakers in the U.S. will embrace this collaborative approach to reshape the industrial landscape.

The path forward demands commitment from everyone involved. But the payoff - both financially and environmentally - makes eco-industrial parks one of the most promising ways to achieve large-scale sustainable industrial growth.

FAQs

How do eco-industrial parks help protect the environment while boosting local economies?

Eco-industrial parks (EIPs) play an important role in cutting down waste, conserving resources, and reducing pollution. These efforts result in cleaner production methods and help lower greenhouse gas emissions. By incorporating renewable energy sources and energy-efficient technologies, EIPs take sustainability efforts to the next level.

Beyond environmental benefits, EIPs contribute to local economies by generating jobs, attracting investments, and driving long-term economic growth. They create a collaborative space where businesses can share resources and cut costs, striking a balance between economic progress and environmental care.

What factors contribute to the success of eco-industrial parks in achieving energy efficiency and collaboration?

Eco-industrial parks thrive by encouraging resource-sharing partnerships among businesses. This means companies exchange energy, materials, and waste streams, reducing waste while boosting efficiency. The key to making this work lies in strong stakeholder involvement and adopting practices that save costs and use resources wisely.

Another driving force is the collaboration between government and industry, which helps set the stage for success. Performance monitoring systems and shared energy initiatives also play a vital role. Together, these efforts not only enhance energy efficiency but also build a cooperative atmosphere that benefits businesses and the local community alike.

What policies can the United States adopt to encourage energy-efficient eco-industrial parks?

The United States has the potential to lead the way in creating energy-efficient eco-industrial parks by implementing policies that promote renewable energy use and better resource management. This could involve providing incentives for adopting clean technologies, simplifying regulations to make investments easier, and encouraging industries to adopt energy-saving practices.

Laws that back market-driven incentives and encourage private sector innovation can push this effort even further. By connecting environmental objectives with economic advantages, such policies can pave the way for industrial hubs that support both businesses and local communities across the country.

Related posts

FAQ

01

What does a project look like?

02

How is the pricing structure?

03

Are all projects fixed scope?

04

What is the ROI?

05

How do we measure success?

06

What do I need to get started?

07

How easy is it to edit for beginners?

08

Do I need to know how to code?

Aug 21, 2025

Case Study: Energy Efficiency in Eco-Industrial Parks

Sustainability Strategy

case-study-energy-efficiency-in-eco-industrial-parks

case-study-energy-efficiency-in-eco-industrial-parks

Eco-industrial parks are reshaping how businesses operate by creating interconnected systems where resources, energy, and waste are shared. This approach reduces costs, improves energy use, and cuts environmental impact. These parks use shared renewable energy systems, advanced energy management tools, and collaborative business models to optimize operations. The result? Lower expenses for companies, cleaner air, and job opportunities for communities.

Key takeaways:

Energy Sharing: Businesses exchange resources like waste heat, steam, and electricity to reduce energy waste.

Energy Mapping: Real-time data identifies inefficiencies and matches renewable energy sources with demand.

Collaborative Management: Joint ownership of energy systems and shared infrastructure drives efficiency.

Global Examples: Kenya's geothermal park, Chicago's food hub, Finland's district heating network, and Canada’s integrated systems highlight successful models.

The U.S. can benefit by implementing policies that support these systems, tailoring solutions to local industries, and encouraging collaboration among businesses, governments, and communities. With the right approach, eco-industrial parks can reduce costs, improve resource use, and support economic growth.

Eco Industrial Park Development - The Ulsan Experience

Design Principles for Energy-Efficient Eco-Industrial Parks

Eco-industrial parks thrive on energy-efficient designs and shared resources, creating systems that cut waste and lower costs. These parks adopt strategies that encourage collaboration among businesses, turning them into interconnected networks. By following key principles, these parks achieve significant energy savings while promoting teamwork, as seen in projects around the globe.

Industrial Symbiosis and Resource Sharing

Industrial symbiosis connects businesses so that one company’s waste, like excess steam or heat, becomes another’s resource. This setup can lead to major energy savings. For example, companies can share steam, hot water, electricity, or even waste heat generated during manufacturing.

This method works best when businesses with complementary energy needs are located close to one another. Picture a steel mill producing excess steam that powers a nearby chemical plant. Or imagine a power plant supplying electricity to several manufacturers while using organic waste as biomass fuel. These partnerships align energy needs and reduce overall costs.

Instead of individual companies investing in smaller, separate renewable energy systems, the entire park can pool resources to install larger, more efficient systems like solar panels or wind turbines. This collective effort not only lowers the cost per kilowatt-hour but also ensures more stable power generation, benefiting all participants.

By aligning energy supply with demand, businesses can maximize the efficiency of shared resources, paving the way for precise energy mapping.

Energy Mapping and Flow Analysis

To optimize energy use, understanding how it flows through an eco-industrial park is critical. Energy mapping tracks power sources, consumption patterns, and waste heat production across all participating businesses. This detailed analysis uncovers opportunities that often go unnoticed when companies operate independently.

With tools like smart meters and sensors, real-time energy flows can be monitored, and inefficiencies quickly identified. For instance, waste heat from a textile manufacturer could be used to power a neighboring food processor’s drying operations. Such insights open doors to energy-sharing opportunities that benefit multiple businesses.

Material flow tracking adds another layer of efficiency by analyzing the movement of raw materials, water, and waste products. For example, a paper mill’s wastewater could generate biogas for electricity, while wood chips from packaging operations might fuel biomass boilers.

Energy mapping also improves the integration of renewable energy systems. Instead of relying on theoretical projections, data-driven insights help determine the best locations for solar panels, wind turbines, and energy storage systems based on actual consumption patterns. This approach ensures renewable energy is used where it’s needed most.

Collaborative Management Models

Identifying energy-saving opportunities is just the beginning - effective management structures are essential to put these ideas into action. Collaborative management models bring together representatives from participating companies to oversee shared infrastructure, energy purchasing, and resource distribution. This ensures that all businesses benefit from the park’s energy initiatives.

Joint ownership of renewable energy installations, like solar farms, allows companies to share costs and reap proportional benefits. Regular coordination meetings help align operations and identify new opportunities for synergy as businesses evolve or invest in new equipment.

Internal financial tools, such as carbon pricing or energy credits, encourage energy-efficient practices. Some parks reward companies that reduce consumption or share resources, while others offer revolving loan funds to support investments in energy-efficient technologies.

Collaboration often extends beyond the park itself. Engaging with local utilities, government agencies, and community stakeholders can secure benefits like favorable electricity rates, regulatory support, and public backing for future expansions. These partnerships make it easier to achieve shared energy goals.

The following case studies demonstrate how these principles come to life, showcasing real-world examples of energy-efficient practices in action.

Case Studies of Energy Efficiency in Eco-Industrial Parks

Examples from around the world show how eco-industrial parks turn energy efficiency concepts into real, measurable results. These parks rethink traditional industrial practices by fostering collaboration, integrating renewable energy, and using strategic planning to benefit both businesses and their surrounding communities.

Here are a few standout examples of how these principles are applied in practice:

KenGen Green Energy Park (Kenya)

Kenya's KenGen Green Energy Park in Naivasha is a trailblazer in renewable energy use across Africa. This facility combines geothermal power production with sustainable industrial operations, creating a blueprint for energy-efficient growth. By utilizing hybrid renewable systems and capturing waste heat to support local agriculture, the park demonstrates how efficient energy management can drive both community growth and operational harmony.

Testa Produce Inc. (Chicago, USA)

Testa Produce Inc., based in Chicago, has overhauled its operations by embracing renewable energy and smart energy solutions. The company has installed solar panels, upgraded to energy-saving lighting systems, and implemented advanced monitoring tools to track and reduce energy use. On top of that, efficient waste processing and optimized cold storage systems have helped the company make better use of resources while improving overall performance.

Harjavalta Eco-Industrial Park (Finland)

Finland’s Harjavalta Eco-Industrial Park highlights the benefits of transitioning to sustainable energy systems. The park has adopted district heating networks, significantly cutting down its reliance on fossil fuels. By fostering collaboration among the businesses within the park, it has enabled resource sharing that boosts energy efficiency while also supporting circular economy initiatives.

Sarnia-Lambton Eco-Industrial Park (Canada)

Located in Ontario, the Sarnia-Lambton Eco-Industrial Park has become a leader in eco-friendly industrial practices. The park integrates renewable energy systems with advanced resource management, bringing together multiple companies dedicated to cutting carbon emissions and improving energy efficiency. Features like diverse renewable installations, energy storage solutions, and integrated water and waste systems form the backbone of its sustainable setup. This transformation has been backed by strong government support and close collaboration among industry players, establishing a model for future eco-industrial developments.

These examples highlight the potential of eco-industrial parks to advance energy efficiency while addressing environmental and community needs. They also provide a foundation for exploring the key factors behind their success and the challenges they face.

Success Factors and Challenges

Success Factors

Transforming traditional industrial parks into energy-efficient eco-industrial systems is no small feat. It requires a well-coordinated effort across several key areas to ensure success:

Collaboration among stakeholders: Bringing together businesses, local governments, and community members is essential. This collective effort creates a foundation for shared goals and meaningful progress.

Access to financial resources and incentives: Government subsidies, tax breaks, and long-term energy savings make the transition more financially appealing, helping to offset initial costs and encourage sustainable practices.

Symbiotic business relationships: When companies within the park share by-products, energy, and water resources, waste is reduced, and overall efficiency improves. This interconnected approach benefits everyone involved.

Advanced technologies: Investments in modern tools like renewable energy systems, cleaner production methods, and advanced monitoring technologies drive continuous improvements and adaptability.

Supportive regulations: Policies and frameworks that encourage sustainable practices are critical for long-term success.

Knowledge sharing and training: Regular education and capacity-building efforts help stakeholders understand the benefits and processes of energy-efficient practices, speeding up adoption across the board.

By focusing on these factors, the transition to eco-industrial systems becomes more achievable, and the overall impact is maximized.

Role of Expert Consulting

Expert consultants play a pivotal role in turning these success factors into actionable strategies. They simplify the complex process of creating eco-industrial parks by aligning stakeholders and streamlining collaboration.

Consultants provide in-depth technical and financial analyses, helping businesses assess energy-sharing opportunities, calculate returns on investment, and design scalable energy models. They also guide organizations through regulatory requirements, ensuring compliance and helping them tap into available incentives.

Beyond analysis, consultants focus on capacity building. Through tailored training programs, they equip leaders and energy managers with the tools and knowledge needed to implement innovative solutions. This hands-on support often determines whether a project encounters roadblocks or achieves lasting success.

Recommendations for the United States

The United States has a unique opportunity to take the lead in developing energy-efficient eco-industrial parks. By learning from successful international models, several strategies can help accelerate progress and make a meaningful difference across the country’s industrial landscape. It all starts with implementing policies that create room for region-specific, tailored solutions.

Policy and Incentive Frameworks

Building a strong policy foundation is crucial for expanding eco-industrial parks nationwide. On the federal level, offering targeted tax credits to companies participating in industrial symbiosis networks could help offset the upfront costs of infrastructure for energy-sharing systems and waste-to-energy projects. At the state level, policies like streamlined permitting can provide additional support. For example, California’s renewable energy zones have shown how pre-approved utility connections and expedited environmental reviews can lower barriers for new projects.

Performance-based incentives can also play a significant role. Multi-year programs that reward companies for meeting specific energy reduction goals encourage ongoing efficiency improvements and innovation. Additionally, partnerships with regional utilities could be a game-changer. Public utility commissions might offer discounted rates to eco-industrial parks that stabilize the grid through demand balancing and distributed energy generation. This approach transforms these parks into assets for the energy grid, rather than just energy consumers.

Customized Solutions

Once supportive policies are in place, solutions tailored to regional needs become essential. The U.S. industrial landscape is incredibly diverse, and strategies should reflect local strengths and conditions. For instance:

In manufacturing-heavy regions like the Great Lakes, thermal energy-sharing networks can allow facilities to exchange waste heat and steam, making use of existing infrastructure.

Technology hubs in states like Texas, North Carolina, and Arizona can integrate data centers with nearby manufacturing plants. Here, the waste heat from data centers could support production processes, while their consistent electricity demand helps stabilize renewable energy sources.

Agricultural areas present opportunities for bio-industrial symbiosis. Food processing plants, biofuel producers, and livestock operations could collaborate to create closed-loop systems, turning organic waste into energy feedstock.

Coastal port cities can leverage their logistics advantages to develop eco-industrial clusters, combining container terminals, freight rail, and distribution centers to optimize energy use and transportation efficiency.

Financing mechanisms should also align with local economic realities. For example, USDA rural development programs could be adapted for eco-industrial projects, or municipal bonds could fund public-private partnerships in urban areas.

Stakeholder Collaboration and Impact Analysis

Collaboration among stakeholders is at the heart of successful eco-industrial initiatives. Regional economic development organizations can bring together manufacturers, utilities, local governments, and community leaders to work toward shared economic and environmental goals.

Data-driven impact analysis is key to keeping stakeholders engaged. Conducting baseline assessments of energy flows, waste streams, and economic impacts can highlight the benefits of eco-industrial practices, such as improved environmental performance, job creation, and increased tax revenue. These assessments also help demonstrate how these initiatives contribute to community well-being.

Pilot projects can serve as a starting point, allowing companies to test energy-sharing arrangements on a smaller scale. These demonstrations provide tangible results and cost-benefit data that can encourage broader participation. By building on proven collaborative models, stakeholders can establish clear impact metrics and foster community engagement, which helps secure the social support needed for eco-industrial development.

Expert consultants, such as Council Fire, can play a vital role in coordinating these efforts. With experience in energy infrastructure and sustainable development, they can help align technical requirements with economic and environmental goals, ensuring that these parks deliver both financial and ecological benefits.

Long-term governance structures are also essential. Eco-industrial parks need ongoing coordination mechanisms that can adapt to changing business conditions, new technologies, and regulatory updates. These structures should include representatives from all key stakeholder groups and provide clear decision-making processes to maintain energy efficiency and economic impact over time.

Conclusion: Driving Change Through Energy-Efficient Eco-Industrial Parks

Real-world examples show that energy-efficient eco-industrial parks aren't just a concept - they deliver measurable results. These case studies highlight how thoughtful planning and collaboration can reshape industrial practices for the better.

To succeed, these parks rely on a few key elements: smart design that encourages industrial symbiosis, active collaboration among stakeholders, and expert guidance throughout the process. Add to that detailed energy mapping and continuous coordination, and you’ve got a strong foundation for future progress, particularly in the U.S.

Regional strategies play a huge role in making these parks effective. In the United States, adapting successful global models to fit local needs and economic conditions is critical. Learning from international successes, while tailoring them to domestic realities, ensures these parks can thrive. Expert organizations, like Council Fire, bring the know-how to align energy projects with broader economic and environmental goals. Their ability to foster collaboration and perform impact analysis helps ensure these parks deliver real benefits for businesses and communities alike.

Eco-industrial parks focused on energy efficiency bring lasting advantages: lower operating costs, better environmental outcomes, and stronger local economies. The real challenge isn’t whether these parks work - it’s how quickly industries and policymakers in the U.S. will embrace this collaborative approach to reshape the industrial landscape.

The path forward demands commitment from everyone involved. But the payoff - both financially and environmentally - makes eco-industrial parks one of the most promising ways to achieve large-scale sustainable industrial growth.

FAQs

How do eco-industrial parks help protect the environment while boosting local economies?

Eco-industrial parks (EIPs) play an important role in cutting down waste, conserving resources, and reducing pollution. These efforts result in cleaner production methods and help lower greenhouse gas emissions. By incorporating renewable energy sources and energy-efficient technologies, EIPs take sustainability efforts to the next level.

Beyond environmental benefits, EIPs contribute to local economies by generating jobs, attracting investments, and driving long-term economic growth. They create a collaborative space where businesses can share resources and cut costs, striking a balance between economic progress and environmental care.

What factors contribute to the success of eco-industrial parks in achieving energy efficiency and collaboration?

Eco-industrial parks thrive by encouraging resource-sharing partnerships among businesses. This means companies exchange energy, materials, and waste streams, reducing waste while boosting efficiency. The key to making this work lies in strong stakeholder involvement and adopting practices that save costs and use resources wisely.

Another driving force is the collaboration between government and industry, which helps set the stage for success. Performance monitoring systems and shared energy initiatives also play a vital role. Together, these efforts not only enhance energy efficiency but also build a cooperative atmosphere that benefits businesses and the local community alike.

What policies can the United States adopt to encourage energy-efficient eco-industrial parks?

The United States has the potential to lead the way in creating energy-efficient eco-industrial parks by implementing policies that promote renewable energy use and better resource management. This could involve providing incentives for adopting clean technologies, simplifying regulations to make investments easier, and encouraging industries to adopt energy-saving practices.

Laws that back market-driven incentives and encourage private sector innovation can push this effort even further. By connecting environmental objectives with economic advantages, such policies can pave the way for industrial hubs that support both businesses and local communities across the country.

Related posts

FAQ

What does a project look like?

How is the pricing structure?

Are all projects fixed scope?

What is the ROI?

How do we measure success?

What do I need to get started?

How easy is it to edit for beginners?

Do I need to know how to code?